Efficient powder-liquid mixing device and rotor thereof

A kind of mixing equipment, powder-liquid technology, applied in the direction of mixer, mixer with rotating stirring device, dissolving, etc., can solve the problems of high powder content and online production process, inconvenient assembly and disassembly, maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

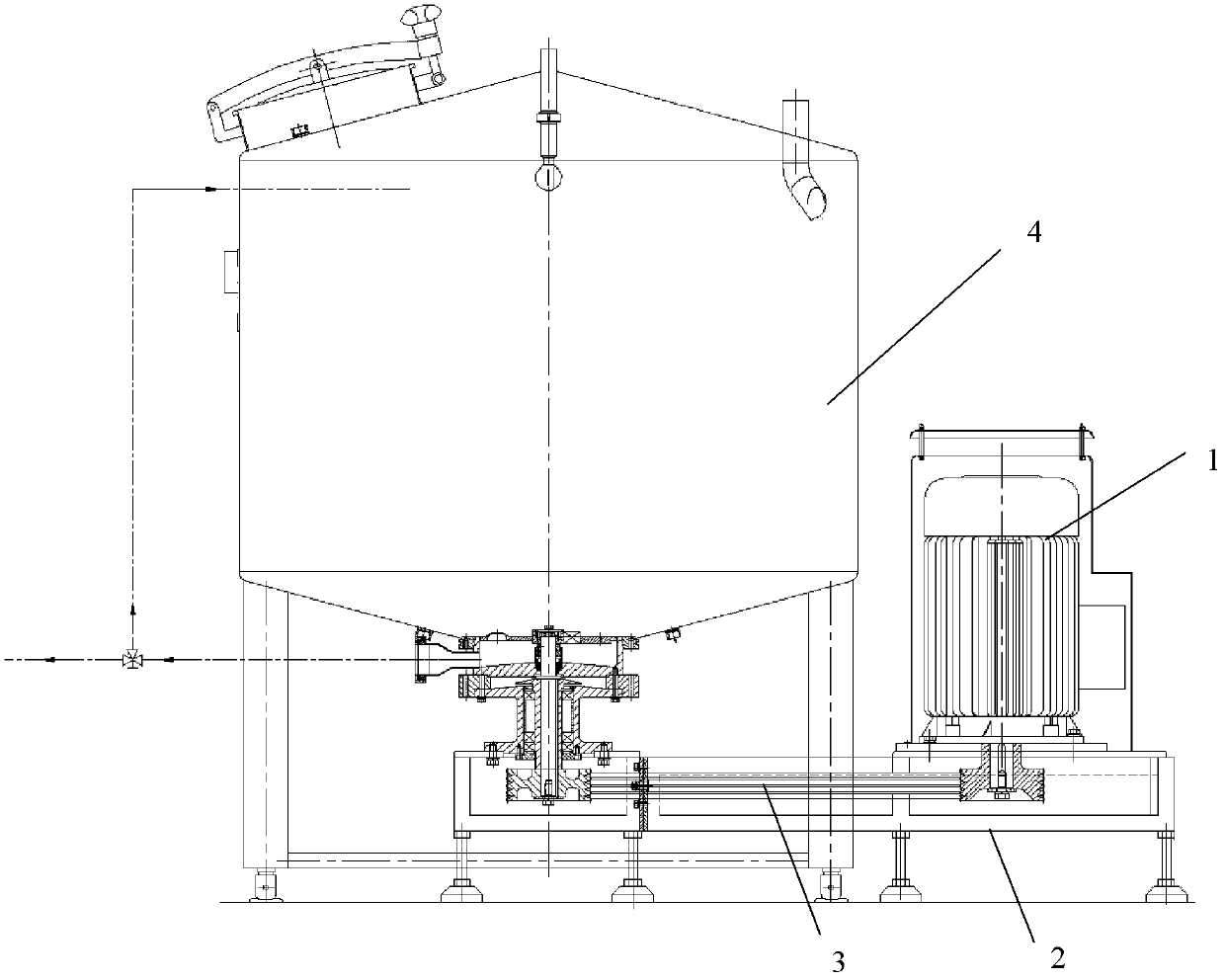

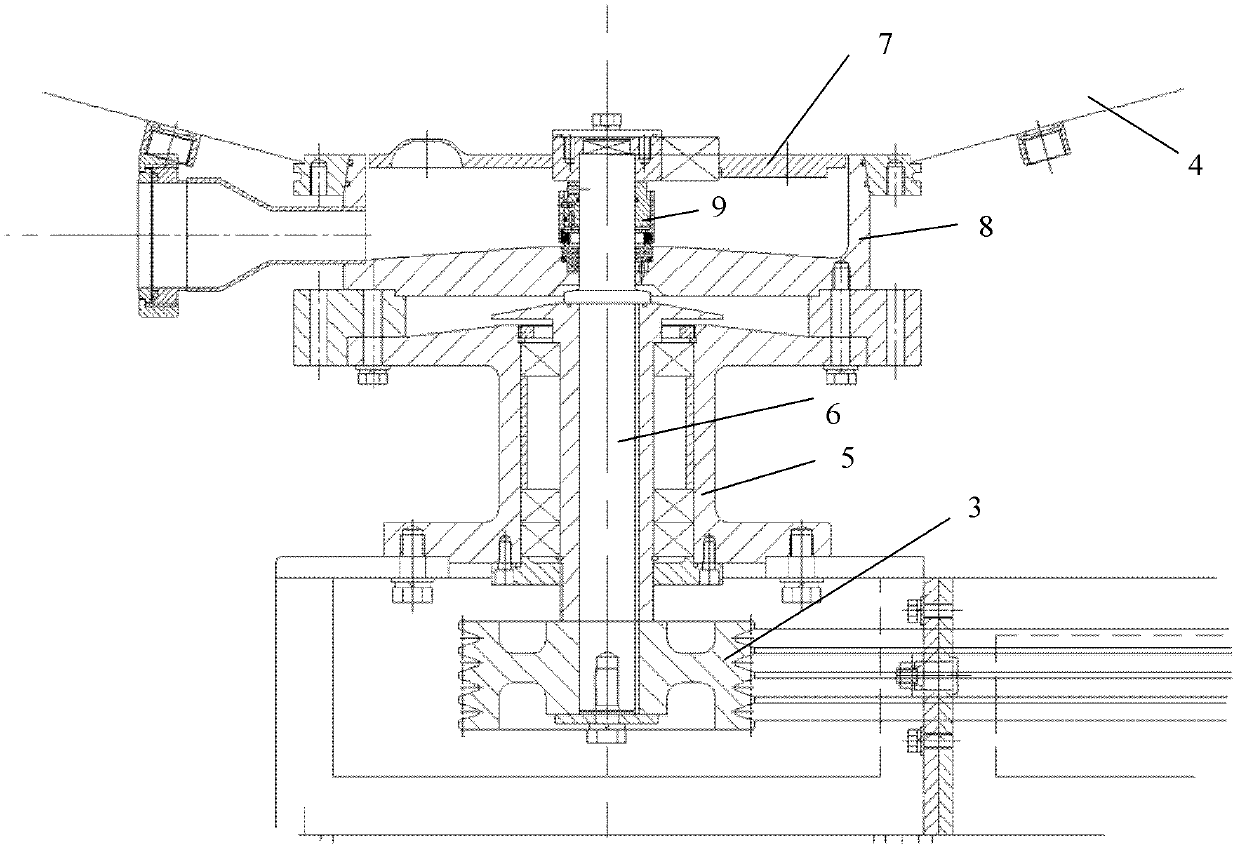

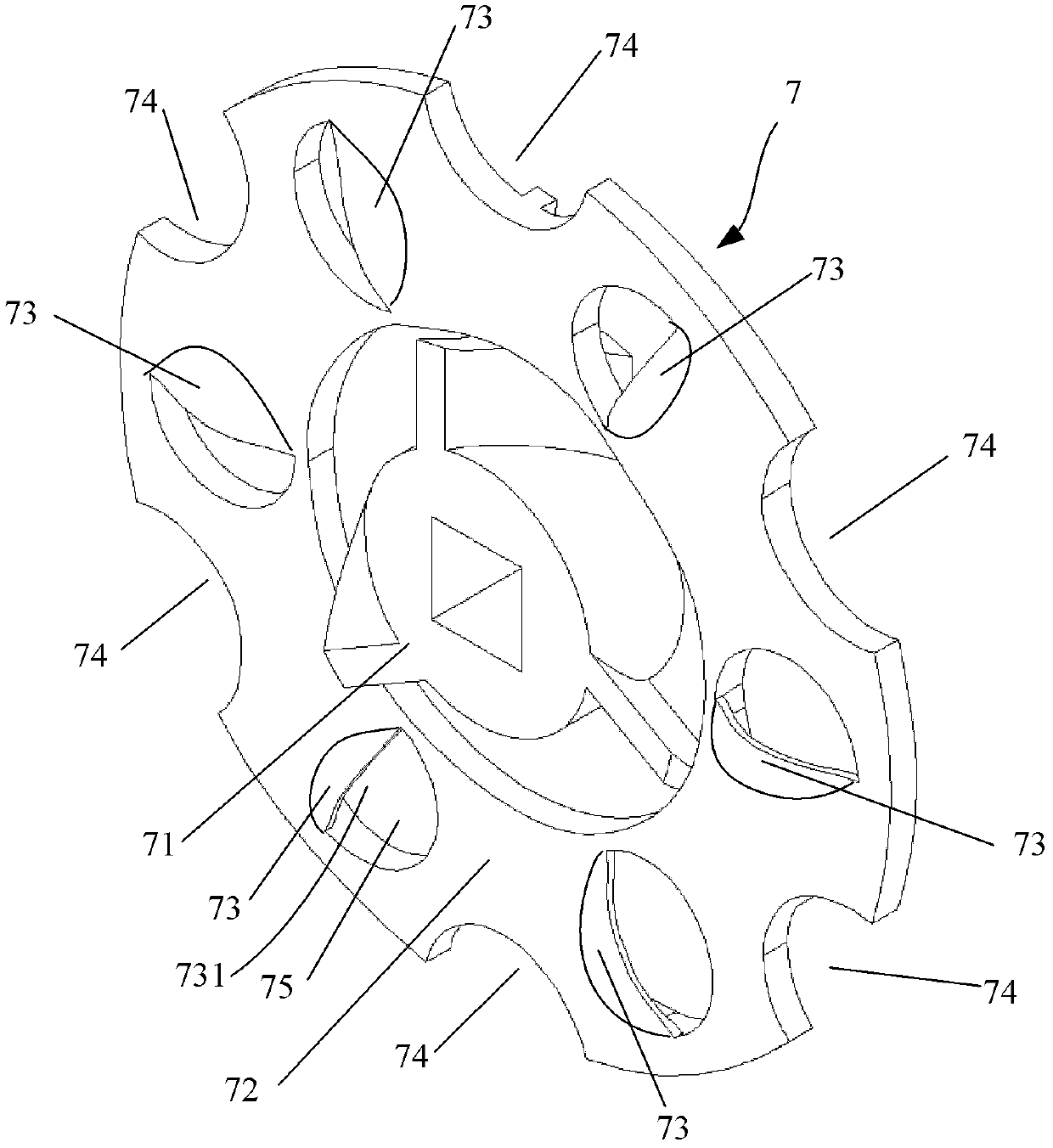

[0016] like figure 1 and figure 2 As shown, the powder-liquid mixing equipment includes a motor 1, a base 2, a belt transmission mechanism 3, a bearing housing 5, a main shaft 6, a rotor 7, a working chamber 8, a mechanical seal assembly 9, and a reaction kettle 4.

[0017] A separate motor 1 and a main shaft 6 are installed on the base 2, and the motor 1 and the main shaft 6 are connected by a belt transmission mechanism 3. The main shaft 6 is rotatably supported by a bearing box 5, and the bearing box 5 is installed on the base 2. The bearing box 5 A working cavity 8 is installed above, and the working cavity 8 is connected to the bottom of the reactor 4 by bolts, and the rotor 7 is installed on the main shaft 6 and is located at the bottom center of the reactor 4 . The hole between the main shaft 9 and the working chamber 8 is sealed by a mechanical seal assembly 9 to prevent powder liquid from penetrating into the gap between the main shaft 9 and the hole of the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com