Fan blade producing method and fan device

A manufacturing method and fan blade technology, applied to other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of weakening the heat dissipation performance of thin fans, limiting the heat dissipation performance of thin fans, and affecting the operation of thin fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The fan device and the method for making the fan blades of the present invention will be further described below with reference to the figures.

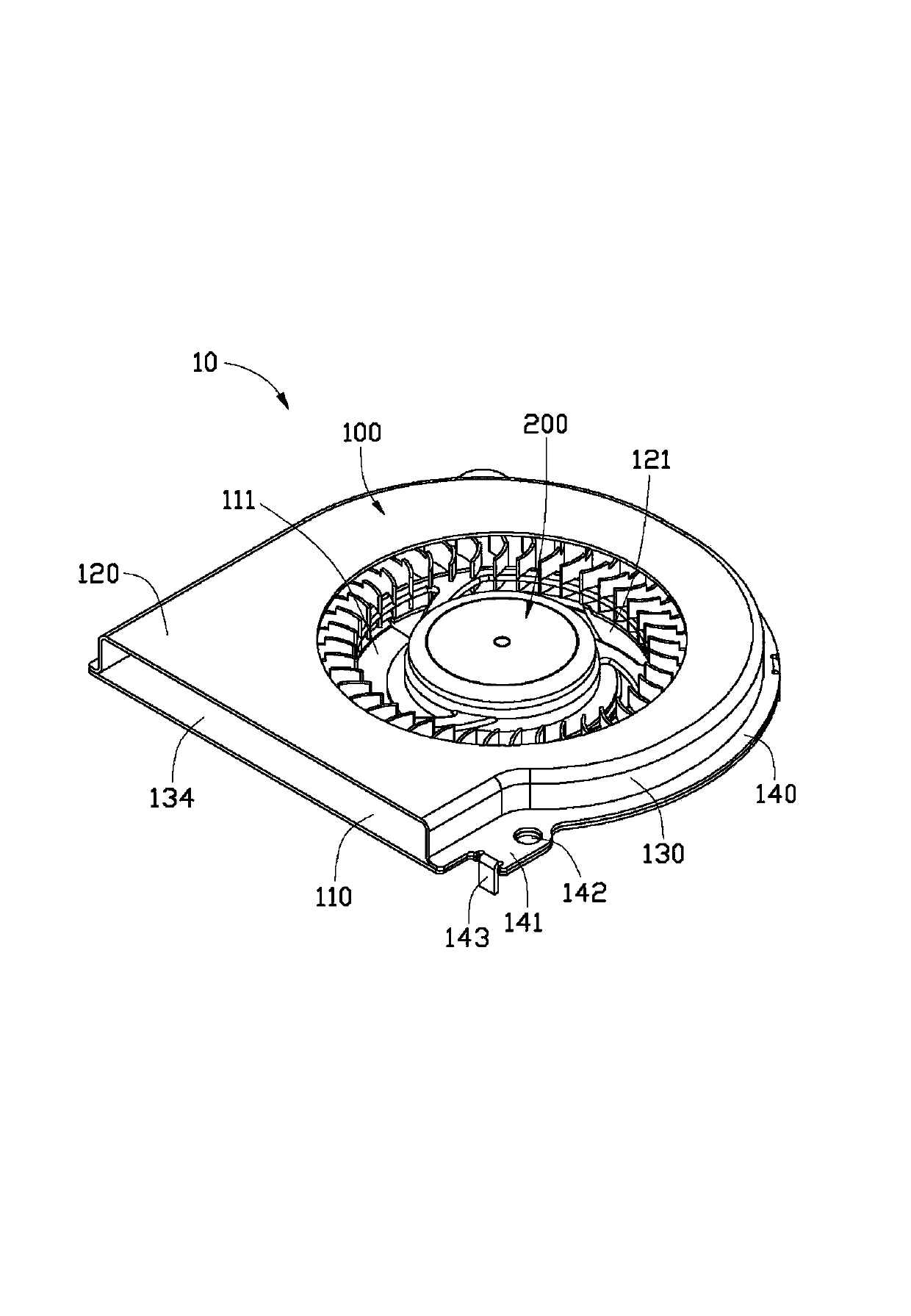

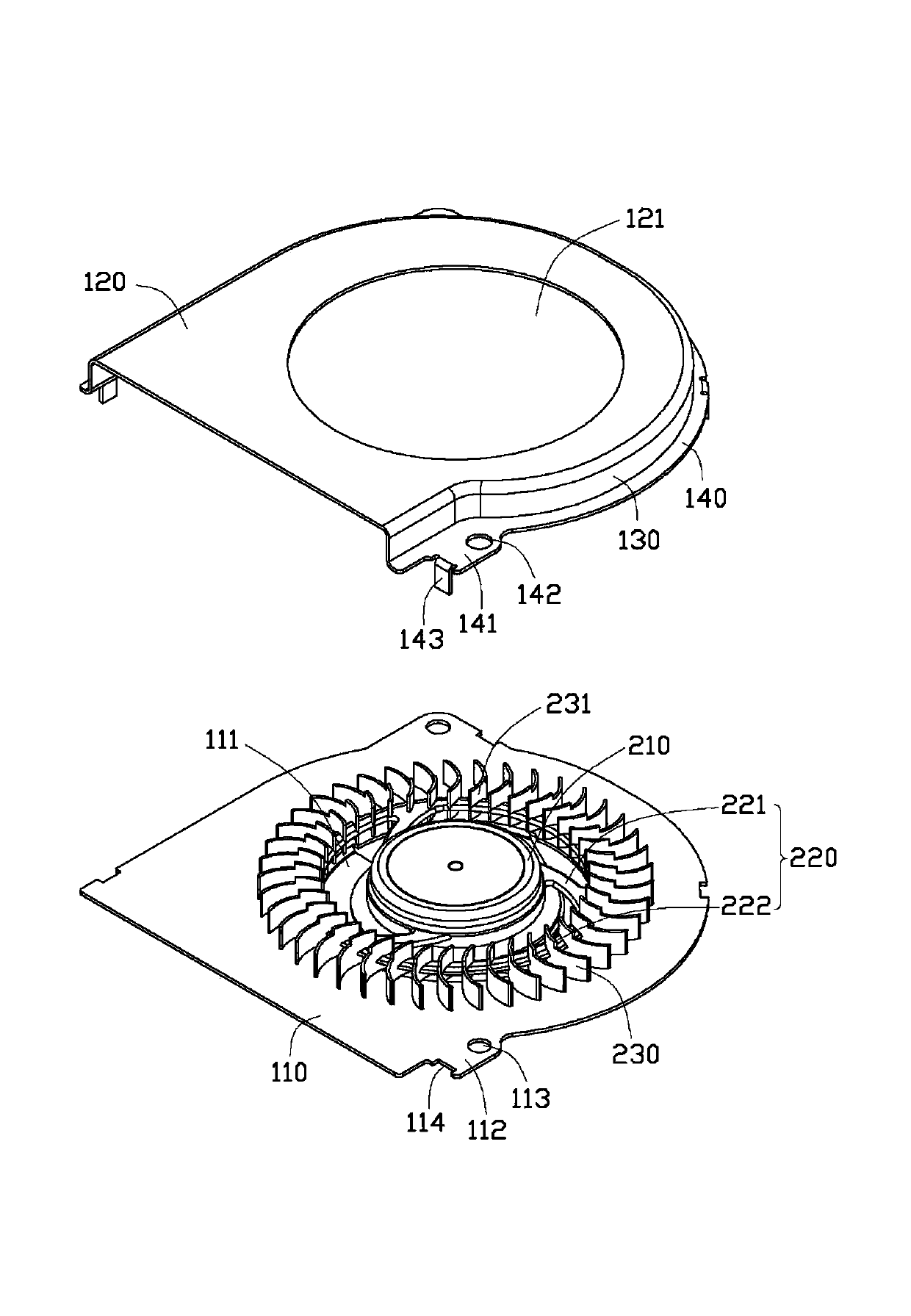

[0021] see figure 1 The fan device 10 provided by the embodiment of the present invention includes a fan frame 100 and a fan blade structure 200 accommodated in the fan frame 100 . The airflow generated by the fan device 10 is used to assist the electronic components to dissipate heat.

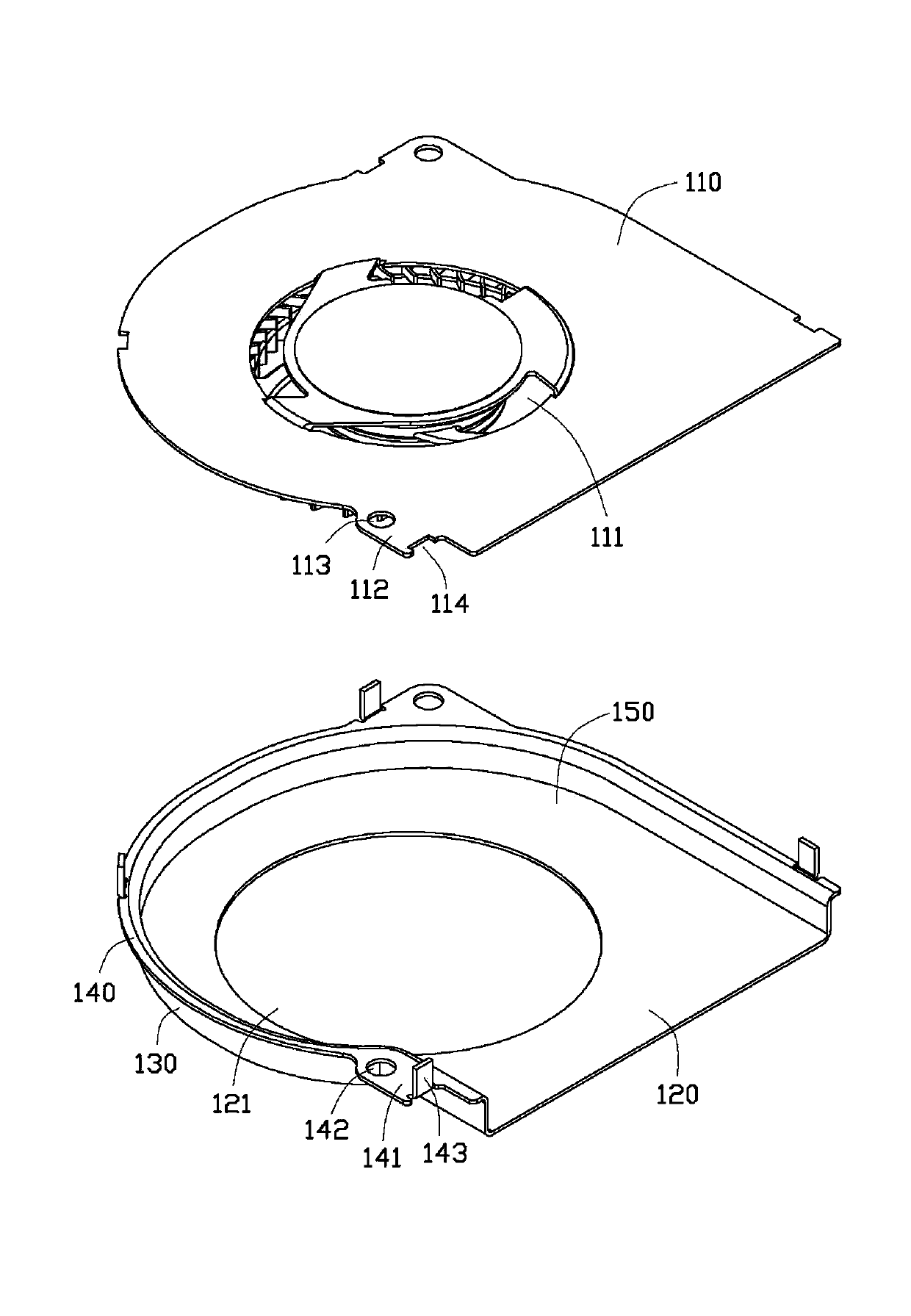

[0022] Please also refer to figure 2 with image 3 The fan frame 100 includes a bottom plate 110 , a cover plate 120 disposed on the bottom plate 110 , and a side wall 130 extending downward from the edge of the cover plate 120 and connected between the bottom plate 110 and the cover plate 120 . An outwardly extending connecting portion 140 is formed at one end of the side wall 130 close to the bottom plate 110 , and the connecting portion 140 is closely attached to the bottom plate 110 . In this embodiment, the cover plate 120 , the side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com