Shaft sealing system for steam turbines

A shaft seal and turbine technology, applied in the field of independent shaft seal systems, can solve problems such as damage to seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] At least one embodiment of the invention is described hereinafter with reference to its application in connection with steam turbine operation. While embodiments of the invention are described with respect to steam turbines, it should be understood that the present teachings are equally applicable to other turbomachinery, including but not limited to compressors. Furthermore, at least one embodiment of the invention is described hereinafter with reference to nominal dimensions and including a set of nominal dimensions. However, it should be apparent to those skilled in the art that the invention is equally applicable to any suitable turbine and / or compressor. Furthermore, it should be apparent to those skilled in the art that the present invention is equally applicable to various orders of magnitude and / or nominal dimensions.

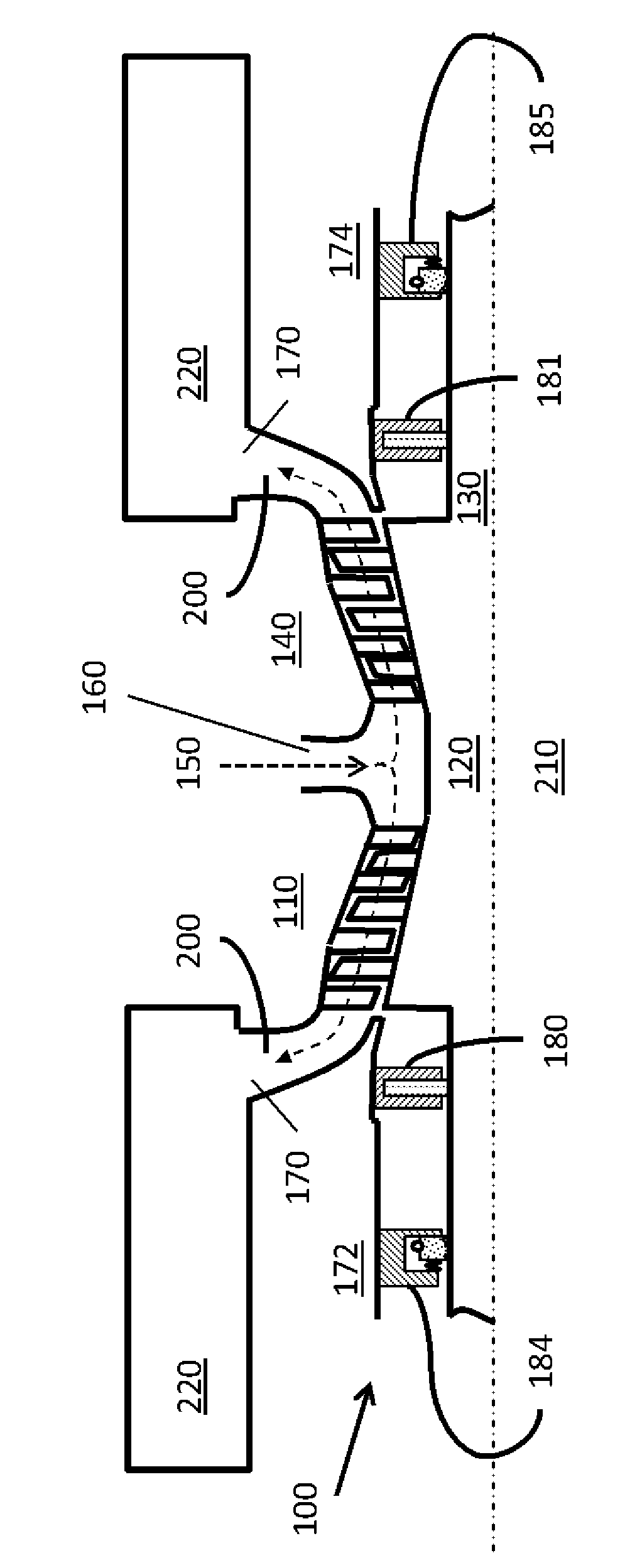

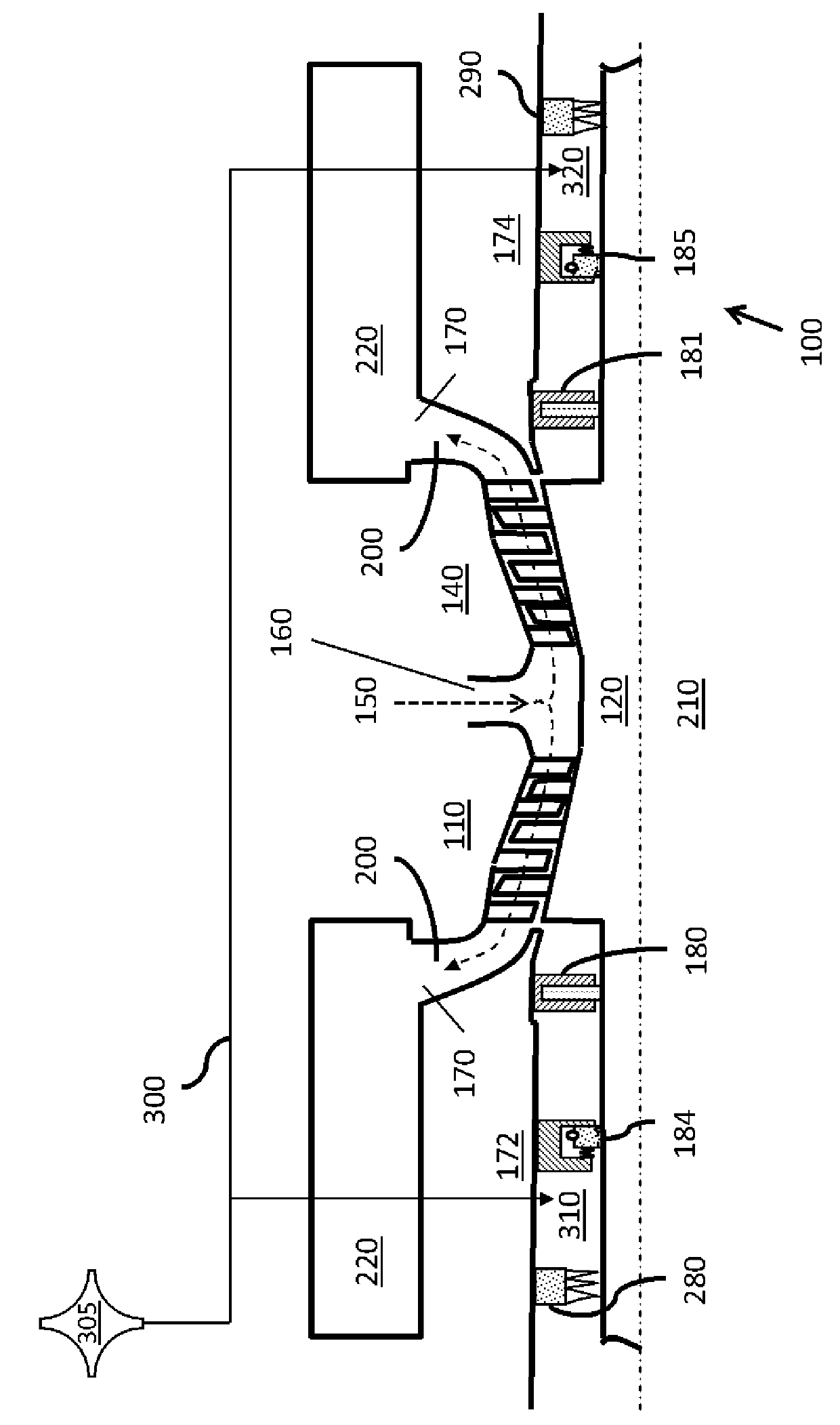

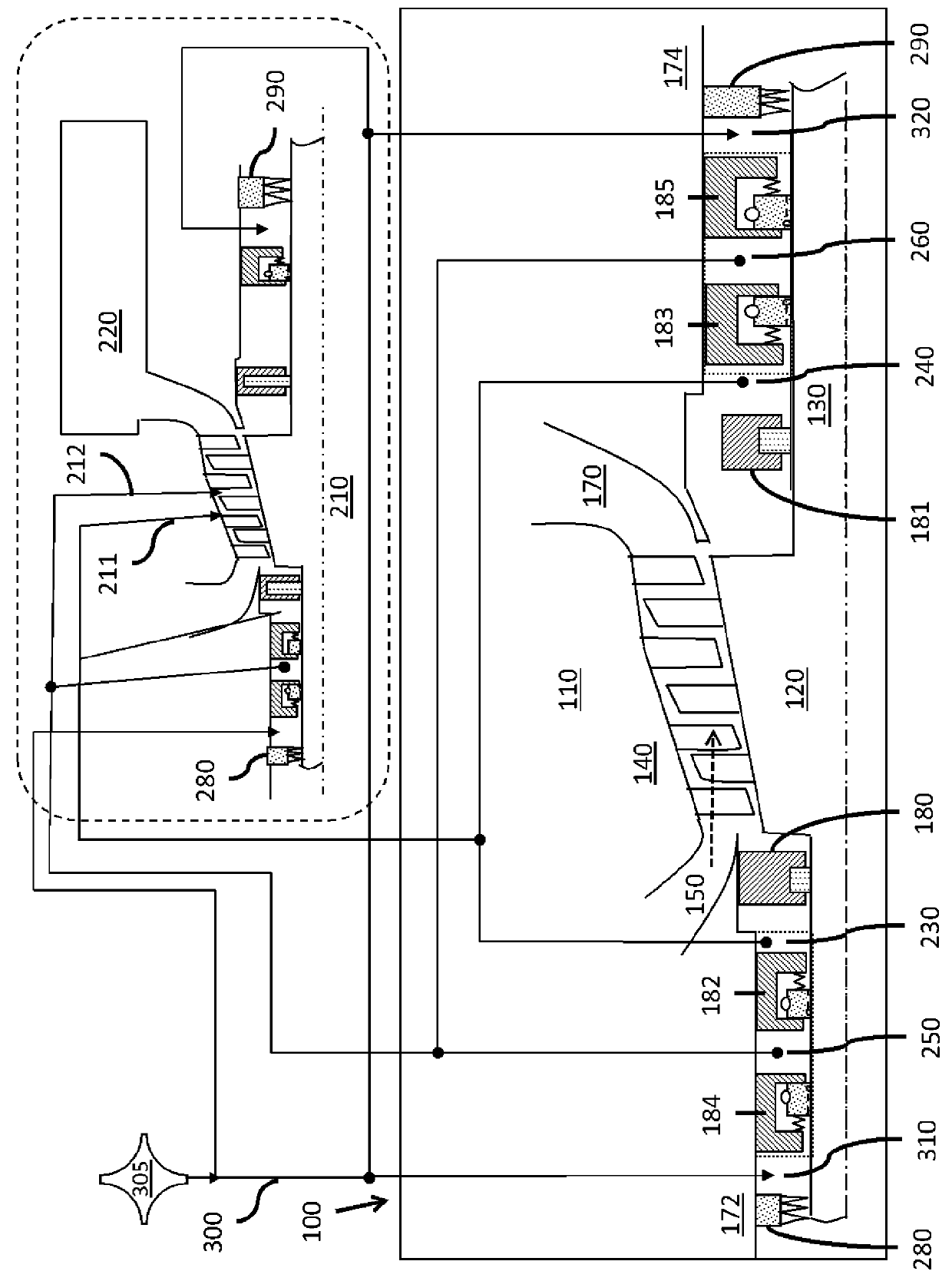

[0057] As noted above, aspects of the present invention provide a shaft sealing system 100, various aspects of which are Figure 1 to Figure 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com