One-step, one-pot process for preparing multiblock and gradient copolymer

A technology for block copolymers and copolymers, applied in the field of one-step, one-pot methods for preparing multi-block and gradient copolymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

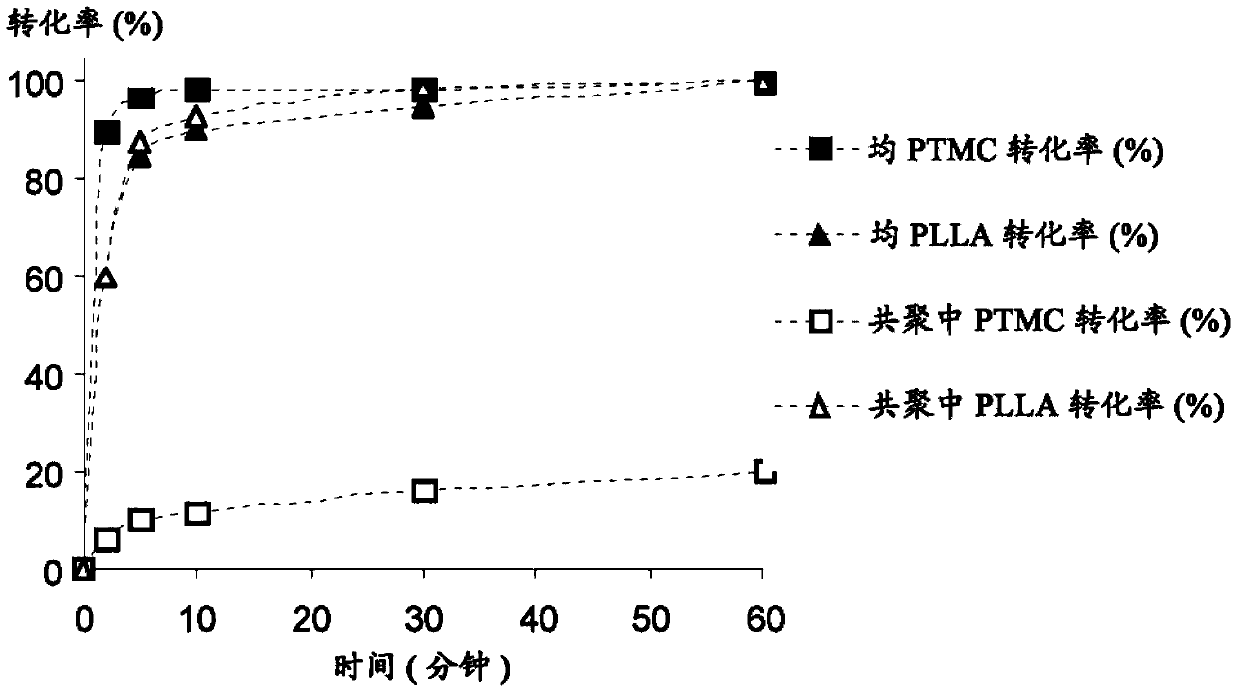

[0093] Using the organometallic complex (BDI) Zn[N(SiMe 3 ) 2 ] Copolymerization of TMC and L-LA in one step, one pot.

[0094]

[0095] Option 4

[0096] The initial ratio [TMC] / [L-LA] / [Zn] / [BnOH] is fixed at 250 / 250 / 1 / 5. The reaction was stopped after a period of 3-360 minutes. The results are shown in Table 1.

[0097] Table 1.

[0098]

[0099]

[0100] a: Mn 理论 is as {[TMC] / [BnOH]×M TMC × conversion rate TMC +([L-LA] / [BnOH]×M L-LA × conversion rate LLA}+M BnOH Calculated, where M L-LA =144g / mol, M TMC =102g / mol, M BnOH =108g / mol.

[0101] b: Determined by SEC (Size Exclusion Chromatography) using polystyrene as reference with correction coefficients of 0.58 for PLLA and 0.73 for PTMC.

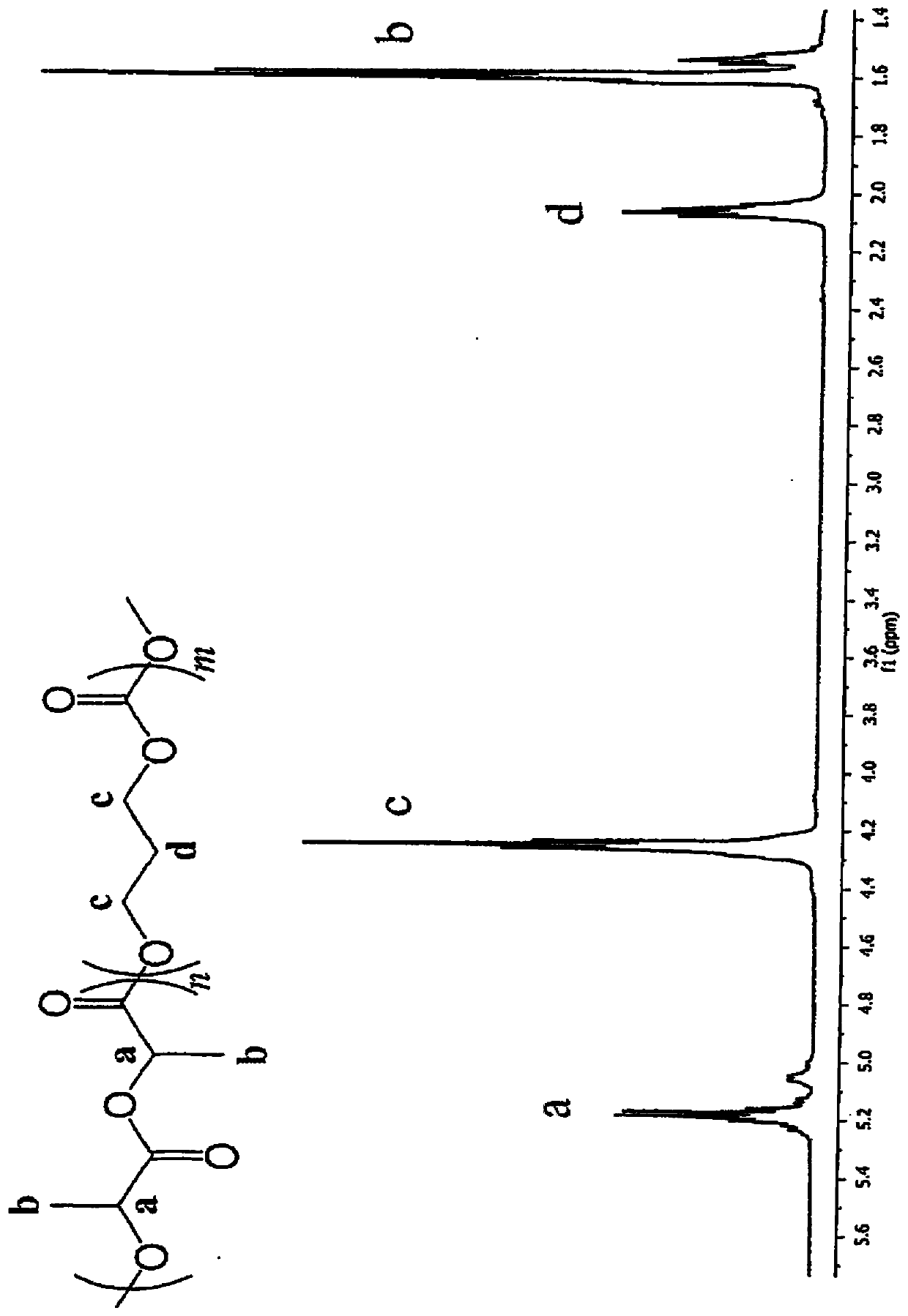

[0102] These results show that for the same ratio of TMC and L-LA, consumption of lactide is much faster than that of cyclic carbonate. Theoretical and experimental molecular weights are in good agreement, and the molecular weight distribution, defined as the rat...

Embodiment 2

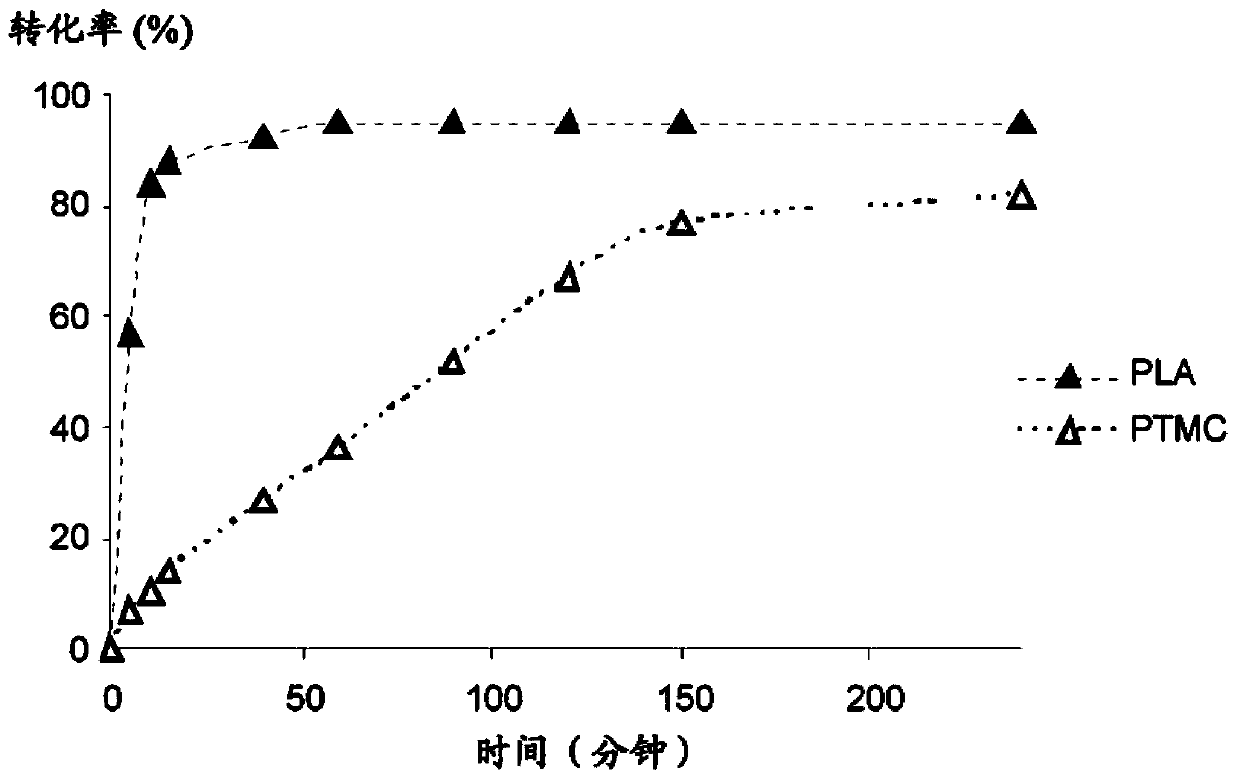

[0110] The percentage of TMC relative to L-LA was varied between 2 and 20% by weight. In toluene solution (2.0M) and at a temperature of 110°C, in the organometallic complex (BDI) Zn[N(SiMe 3 ) 2 ] and benzyl alcohol (BnOH) in the presence of polymerization. The ratio of [LLA] / [Zn] / [BnOH] is fixed at 1500 / 1 / 5. The reaction was stopped after a period of 0.5-24 hours to ensure that complete conversion of the monomers was achieved. The results are shown in Table 3.

[0111] table 3.

[0112]

[0113] a: The reaction time corresponds to the time necessary for complete conversion of each monomer.

[0114] b: Mn 理论 is as {[TMC] / [BnOH]×M TMC × conversion rate TMC +([LLA] / [BnOH]×M LLA × conversion rate LLA}+M BnOH Calculated, where M LLA =144g / mol, M TMC =102g / mol, M BnOH =108g / mol.

[0115] c: Determined by SEC (Size Exclusion Chromatography) using polystyrene as reference, with correction coefficients of 0.58 for PLLA and 0.73 for PTMC.

[0116] As can be seen f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com