Screen frame positioner for screen photosensitive plate making and rapid and accurate positioning method thereof

A technology of positioner and screen frame, which is used in printing plate preparation, printing and other directions, can solve the problems of difficult to guarantee positioning accuracy, poor positioning accuracy, and unsatisfactory manual positioning accuracy, and achieve the effect of improving positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

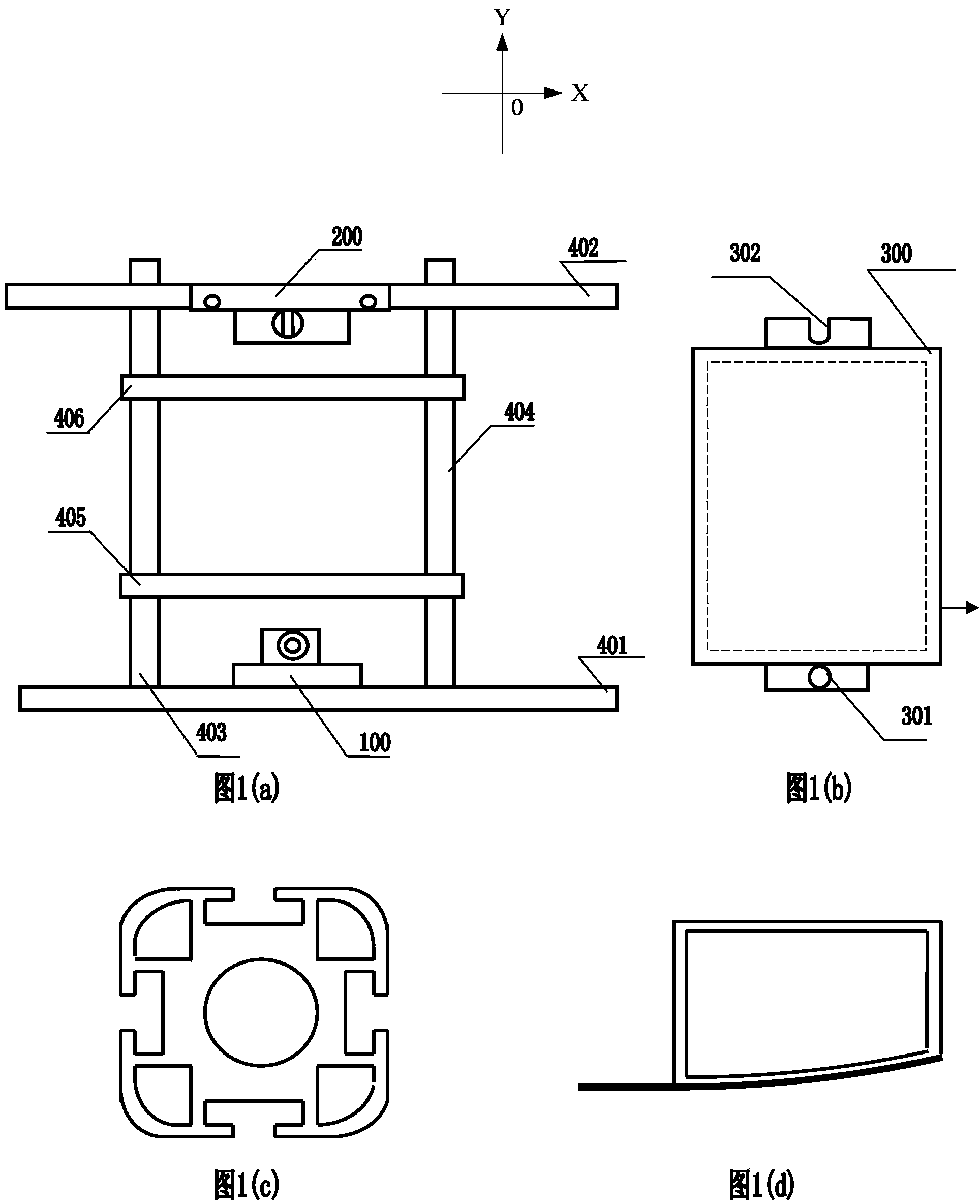

[0038] like figure 1 As shown, the screen frame positioner for the screen photosensitive plate-making of the fixed platen screen printing is composed of a conical ejector pin positioning device 100, a trapezoidal ejector pin positioning device 200, a screen frame 300 for installing a polymer photosensitive film screen, and a positioning screen frame The fixed frame composition;

[0039] The fixed frame adopts MC-8-4040B aluminum profile, and the fixed frame includes X-axis positioning rod 401, X-axis auxiliary positioning rod 402, first Y-axis positioning rod 403, second Y-axis positioning rod 404, and first Z-axis positioning rod 405 and the second Z-axis positioning rod 406,

[0040] The X-axis positioning rod 401, the X-axis auxiliary positioning rod 402, the first Y-axis positioning rod 403, and the second Y-axis positioning rod 404 are assembled to form a rectangular frame, and the first Z-axis positioning rod 405 and the second Z-axis positioning rod 406 are placed Abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com