A marking mechanism of a solar film thermal transfer marking machine

A thermal transfer printing and marking machine technology, applied in typewriters, printing, etc., can solve the problems of damaged marked items, failure to meet different needs of customers, and inability to place large blocks of engraved patterns, etc., to achieve the effect of ensuring normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

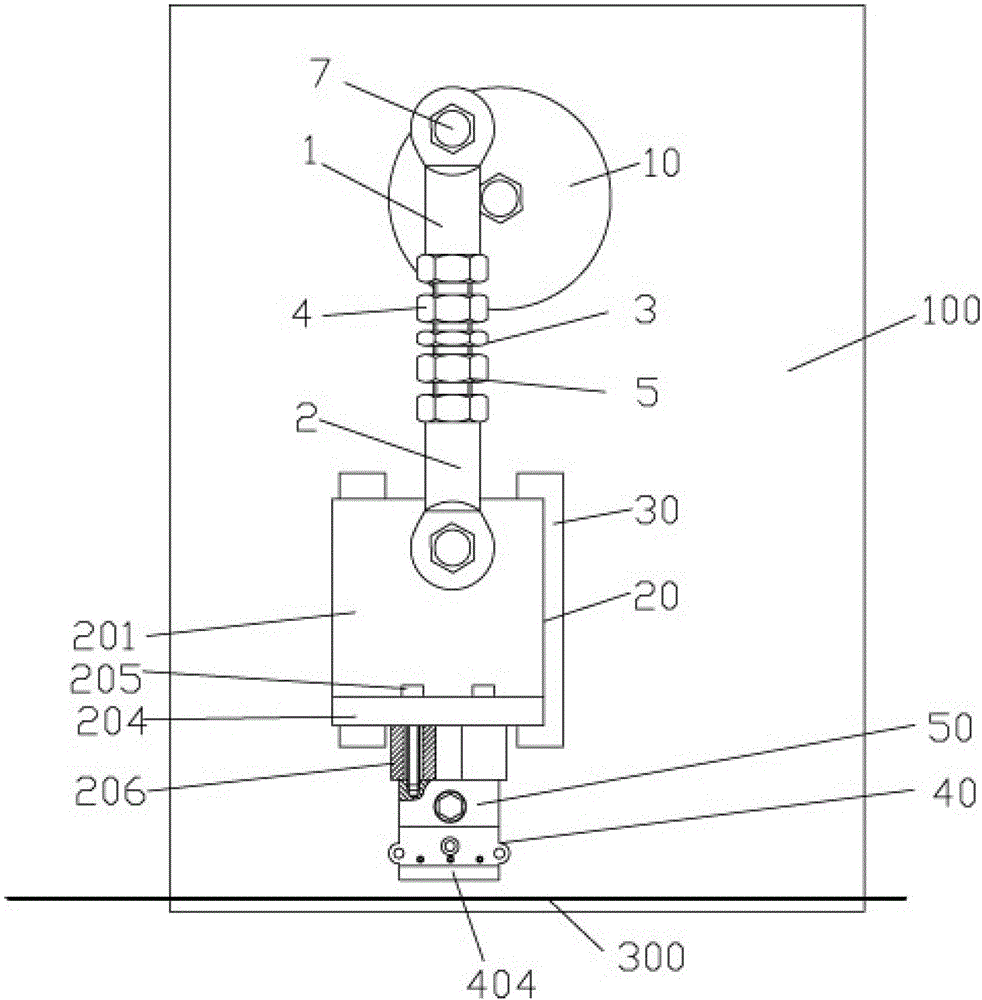

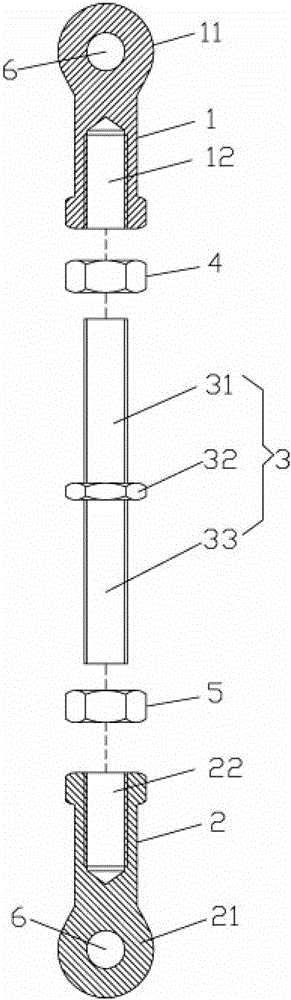

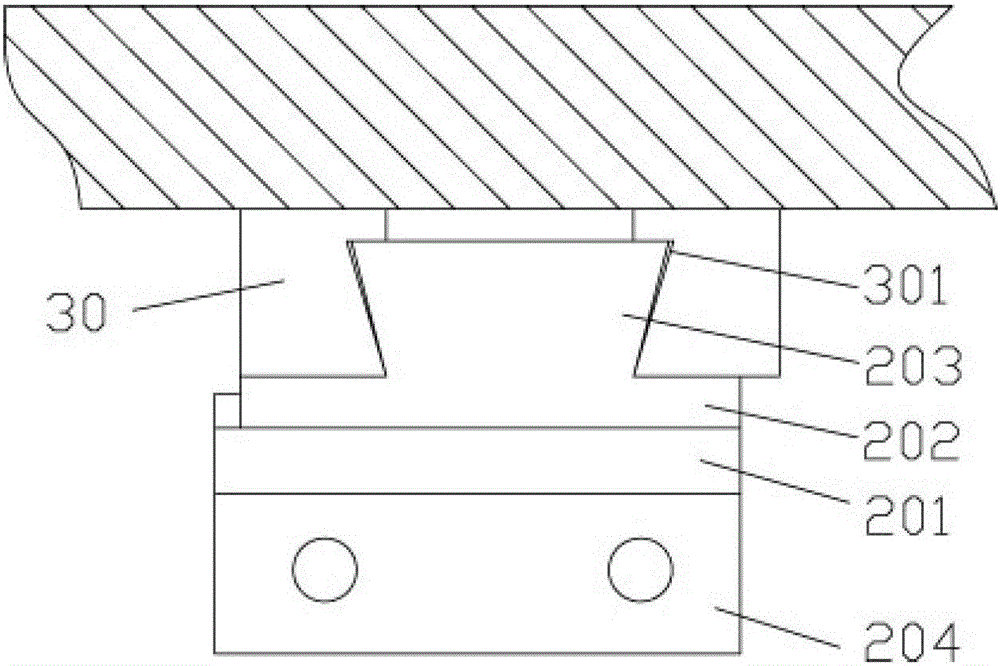

[0025] Examples, see e.g. Figures 1 to 8 As shown, a marking mechanism of a solar film thermal transfer marking machine includes a support plate 100 and a servo motor 200, the servo motor 200 is fixed on the back of the support plate 100, and the rotating shaft 2001 of the servo motor 200 is inserted into the support plate 100 Up and out the front of the support plate 100, the top of the rotating shaft 2001 is fixed with a rotating disk 10, the first oblate part 11 of the upper connection sleeve rod 1 of the telescopic device is fixed on the side of the rotating disk 10, the lower part of the telescopic device The second oblate part 21 of the connecting sleeve rod 2 is hinged on the sliding block 20, and the sliding block 20 is inserted into the sliding rail 30 fixed on the front of the support plate 100, and the bottom of the sliding block 20 is fixed with a heating block 50 for heating. A marking device 40 is fixed on the bottom surface of the block 50 , and the marking blo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap