Flame-retardant wool blended yarn and production method thereof

A technology of wool blending and yarn, which is applied in the direction of yarn, textiles and papermaking, etc. It can solve the problems of poor air permeability, low thermal performance of yarn, and low strength of blended yarn, so as to overcome strong rigidity, ensure yarn quality, reduce The effect of electrostatic phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

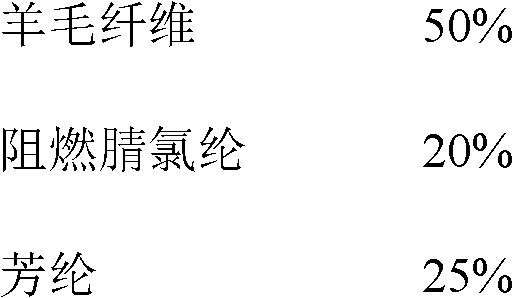

[0035] Formula: (percentage by weight)

[0036]

[0037]

[0038] 2% of the total weight of wool fiber, flame retardant acrylic fiber, aramid fiber and conductive fiber and wool oil;

[0039] The yarn number is 21tex;

[0040] Preparation:

[0041] (1) Raw material pretreatment:

[0042] Add wool fiber, flame retardant acrylic fiber, aramid fiber and conductive fiber, and let it stand for 24 hours for health treatment;

[0043] (2) Cotton blending step: send the pretreated raw materials into the cotton blender, and mix each fiber;

[0044] (3) Opening: The beater speed of the cotton opener is configured at 500r / min; the distance between the dust rods: the inlet group is 12mm, the middle two groups are 8mm, and the outlet group is 6mm; the distance between the beater and the feeding roller is 9mm; the distance between the beater and the dust rod The inlet is 16mm and the outlet is 20mm; the distance between beater and cotton stripper is 1.5mm;

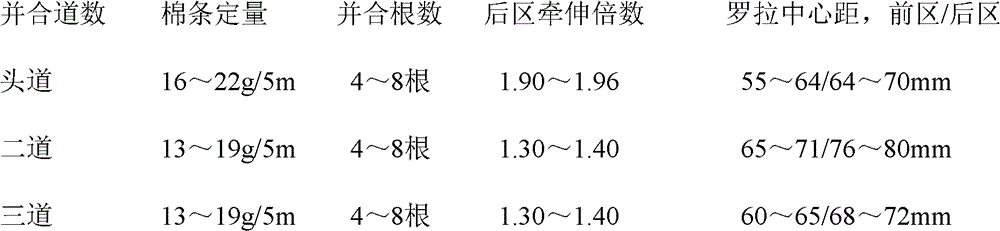

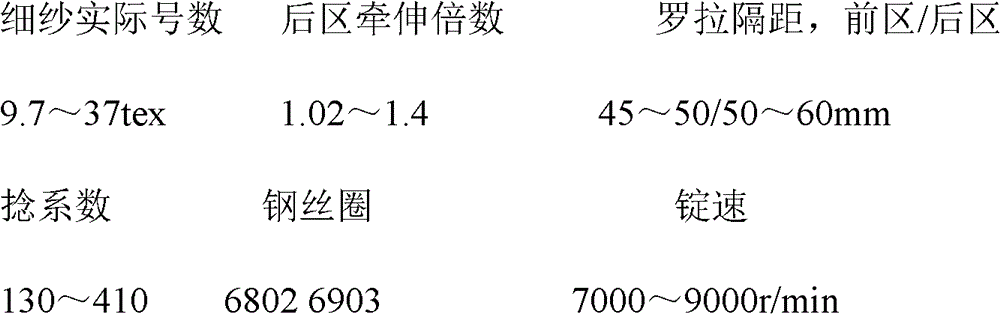

[0045] (4) Clear flow...

Embodiment 2

[0060] formula:

[0061]

[0062] 1.5% of the total weight of wool fiber, flame-retardant acrylic fiber, aramid fiber and conductive fiber and wool oil;

[0063] The yarn number is 37tex

[0064] Preparation:

[0065] (1) Raw material pretreatment:

[0066] Add wool fiber, flame retardant acrylic fiber, aramid fiber and conductive fiber, and let it stand for 30 hours for health treatment;

[0067] (2) Cotton blending step: the pretreated raw materials are sent into a cotton blender, and each fiber is mixed, and the cotton blender can adopt general equipment;

[0068] (3) Opening: The beater speed of the cotton opener is configured at 600r / min; the distance between the dust rods: the inlet group is 11mm, the middle two groups are 6mm, the outlet group is 4mm; the distance between the beaters and the feeding rollers is 8mm; the distance between the beaters and the dust rods The inlet is 10mm and the outlet is 16mm; the distance between beater and cotton stripper is 1.5mm....

Embodiment 3

[0084] formula:

[0085]

[0086] 1% of the total weight of wool fiber, flame-retardant acrylic fiber, aramid fiber and conductive fiber and wool oil;

[0087] The yarn number is 14.6tex

[0088] Preparation:

[0089] (1) Raw material pretreatment:

[0090] Add wool fiber, flame retardant acrylic fiber, aramid fiber and conductive fiber, and let it stand for 24 hours for health treatment;

[0091] (2) Cotton blending step: the pretreated raw materials are sent into a cotton blender, and each fiber is mixed, and the cotton blender can adopt general equipment;

[0092] (3) Opening: The beater speed of the cotton opener is configured as 450r / min; the distance between the dust rods: the inlet group is 15mm, the middle two groups are 10mm, the outlet group is 7mm; the distance between the beaters and the feeding rollers is 8mm; the distance between the beaters and the dust rods The inlet is 10mm and the outlet is 16mm; the distance between beater and cotton stripper is 2mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com