Triangle of high device number towel machine and design method

A towel machine, high machine gauge technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of knitting needles falling, easy knocking off of needle heels, and inability to produce terry cloth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

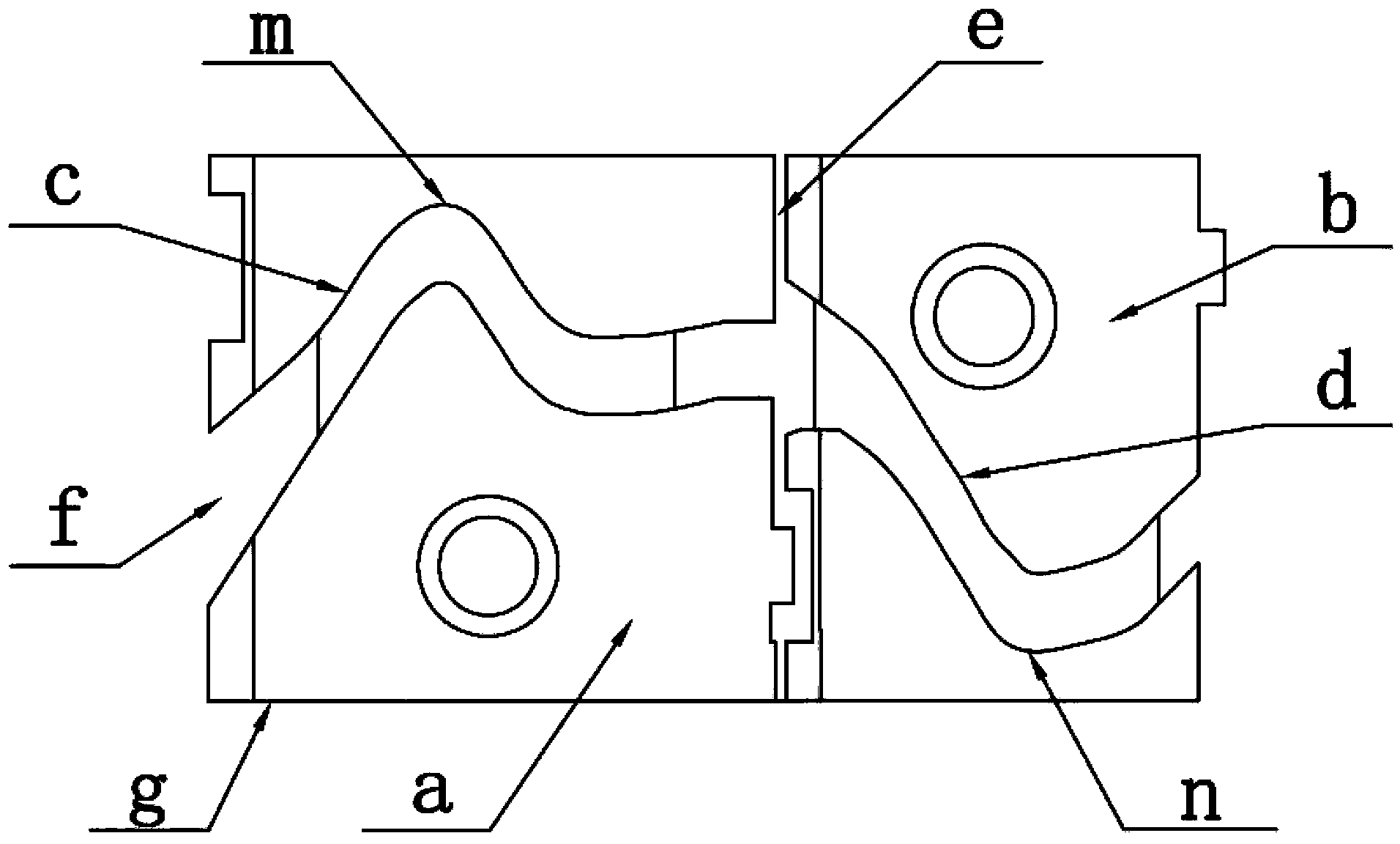

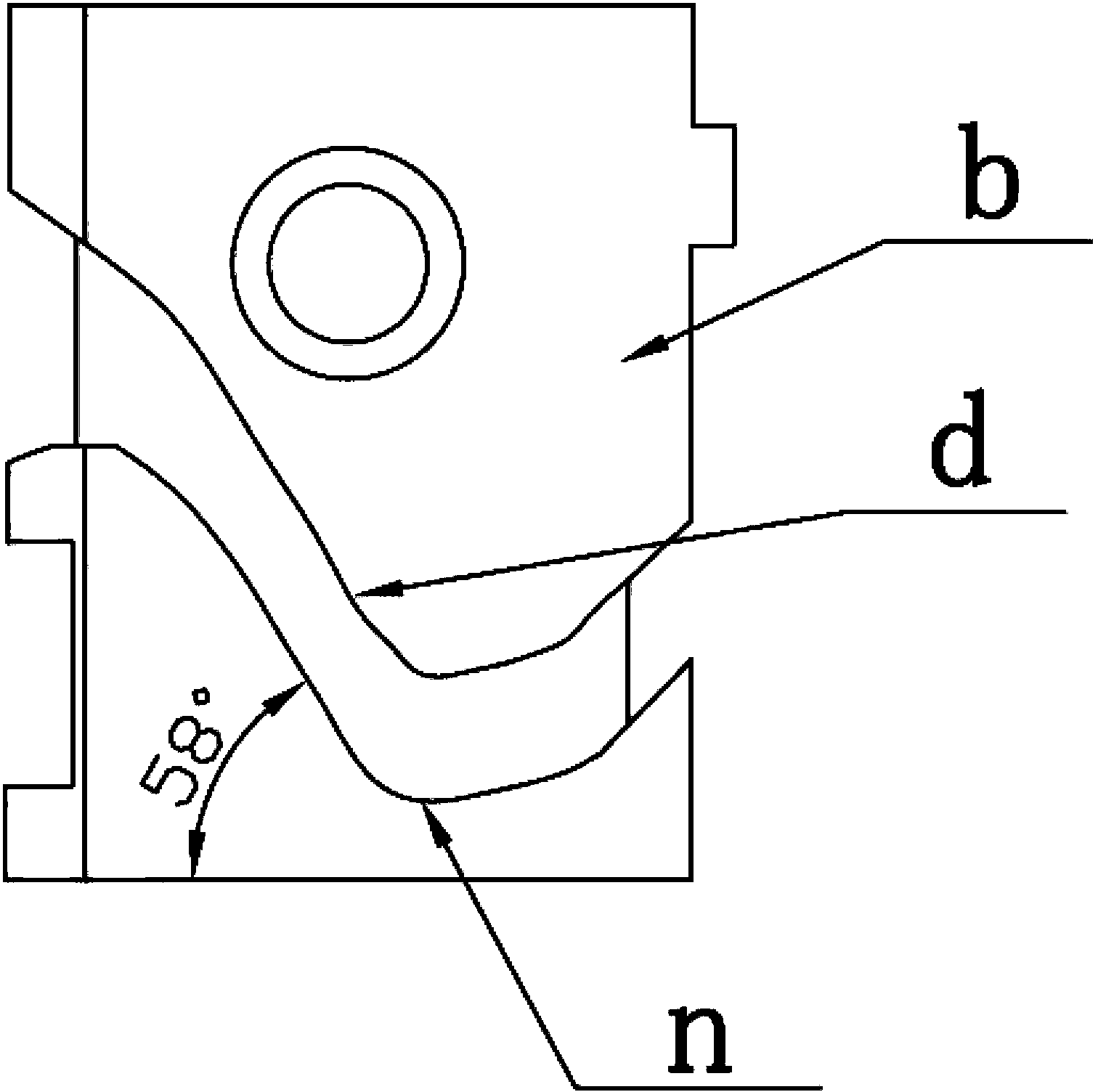

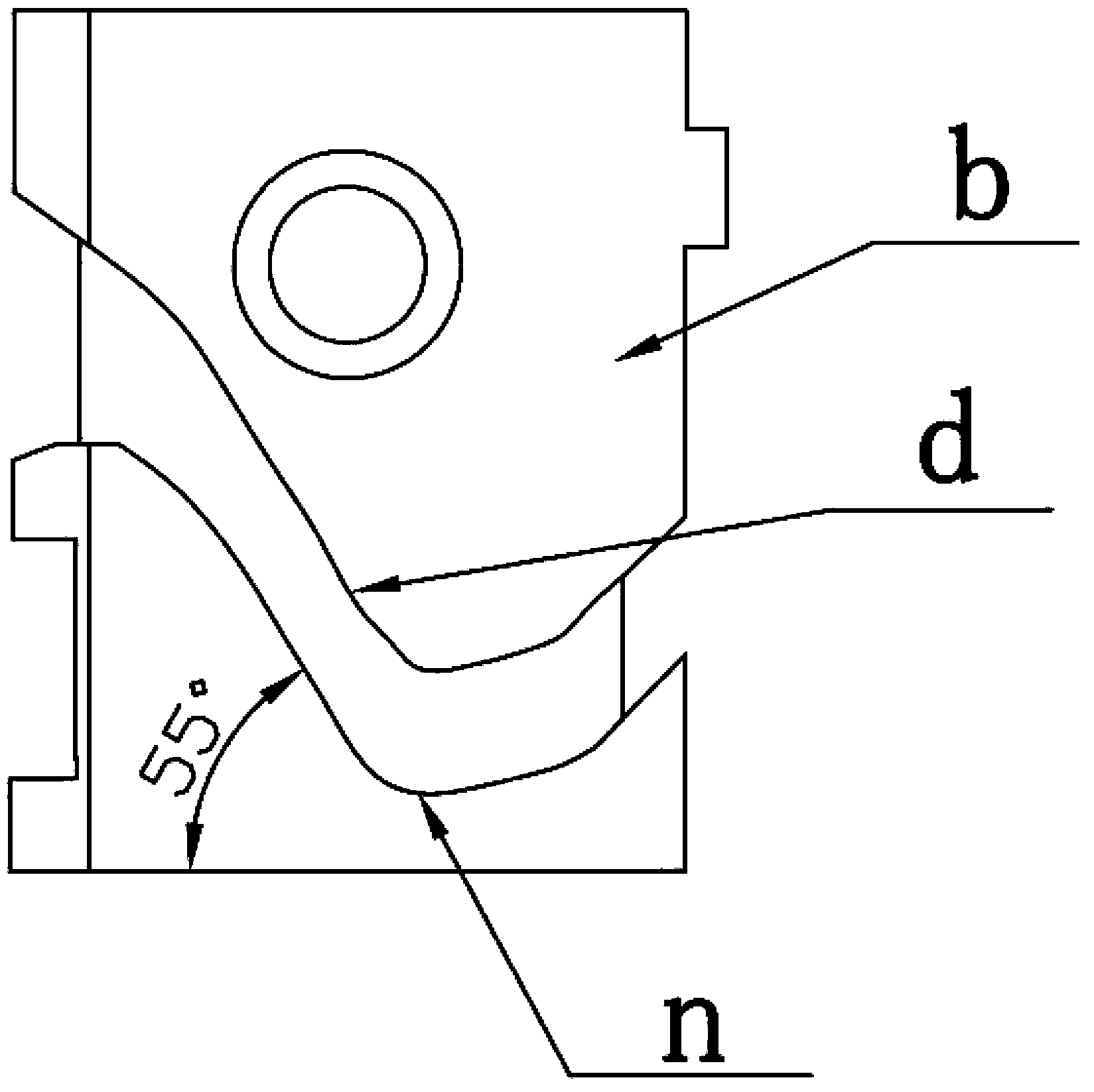

[0025] The high-gauge circular knitting machine uses the regular 26” / 24G towel machine of Singapore Lida Company, with a total of 52 channels. The 36G high-gauge needle cylinder is replaced, and the total number of needles is 2940N. The highest point m of the needle on the needle triangle a is designed 0.50mm lower than the original triangle, the corresponding starting curve track c slows down accordingly, reducing the triangle gap e from the original 0.20mm to 0.10mm, preventing the knitting needle from falling, and maintaining the bending yarn on the bending triangle b On the basis that the height of the lowest point n remains unchanged, the width of the bending triangle b is made 0.10 mm, and the corresponding bending curve track d is correspondingly slowed down. The slope of the bending curve track d is changed from the original 58 degrees to a suitable The high machine number towel machine runs at 55 degrees, which flattens the triangular curve track and reduces the load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com