Armored pipeline butterfly optical cable and production method thereof

A butterfly-shaped optical cable and a manufacturing method technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of poor protection of optical cables and inability to pass through horizontal pipes in batches, etc., and achieve the effects of simple and reliable manufacturing process, good bending performance, and increased capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

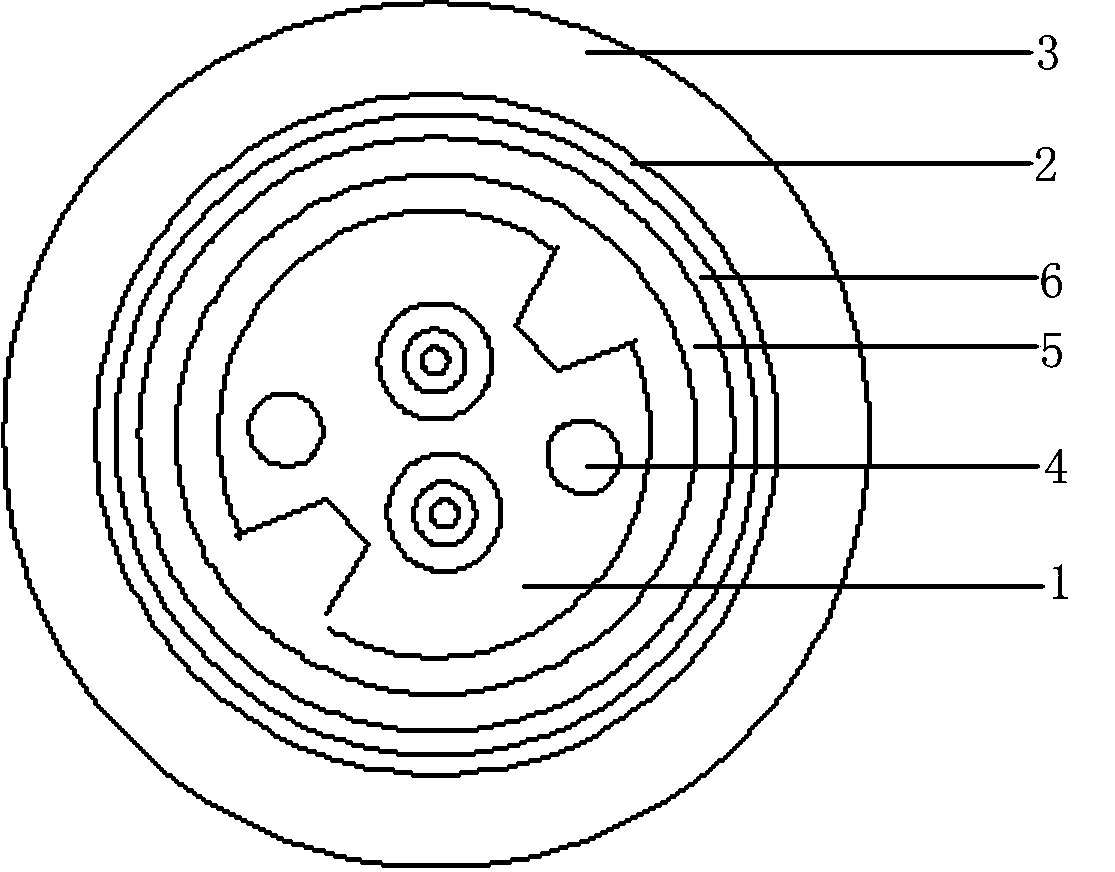

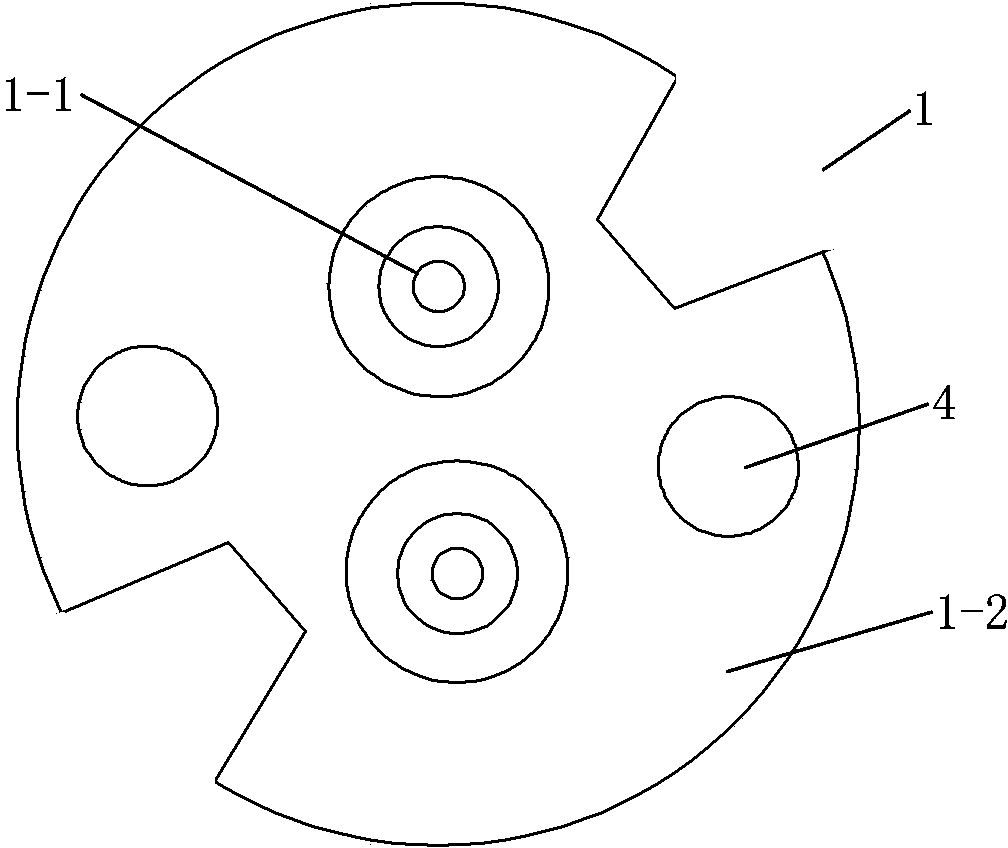

[0033] Referring to attachments 1 and 2, the armored butterfly cable includes a circular butterfly cable unit 1, parallel metal or non-metallic reinforcements 4, water-blocking tape layer 6, steel tape armored longitudinal cladding 2 and outer sheath 3. An optical fiber 1-1 is arranged in the circular butterfly cable unit 1 . The optical fiber 1-1 is a tight-packed optical fiber, and parallel metal or non-metallic reinforcements 4 are arranged on both sides of the optical fiber 1-1 to improve tensile performance, and the outside is covered with a slotted sheath 1-2. The circular butterfly optical cable unit 1 is provided with non-metallic tensile elements (aramid fiber or tearing rope) 5 up and down, and the circular butterfly optical cable unit 1 is longitudinally covered with a water-blocking tape layer 6, which is armored outside the water-blocking tape layer 6 Steel tape armored longitudinal cladding 2 is provided, and an outer sheath 3 is molded outside the steel tape arm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com