Multi-channel symmetrical flushing device and method for micro-hole EDM-electrolysis combined machining

A technology of combined machining and EDM, which is applied in the fields of liquid flushing devices, multi-channel symmetrical flushing devices for micro-hole EDM-electrolysis combined processing, and EDM-electrolysis combined processing flushing devices. Problems such as combined processing, inability to realize the internal flushing process, and inability to use EDM to achieve the effect of improving the hole-making effect, improving the machining accuracy and surface quality, and simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

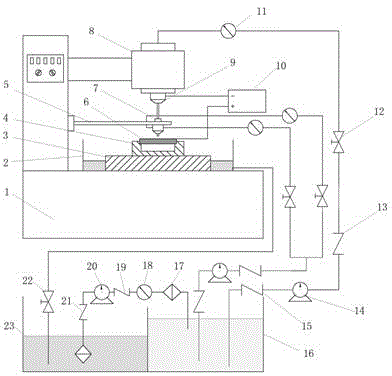

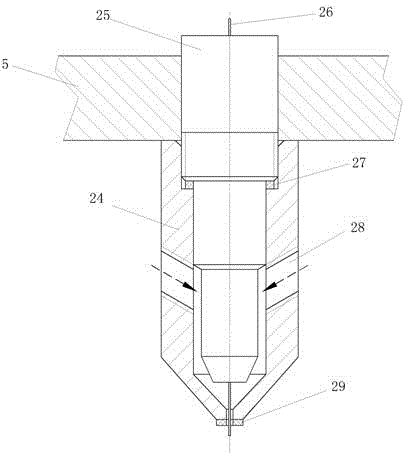

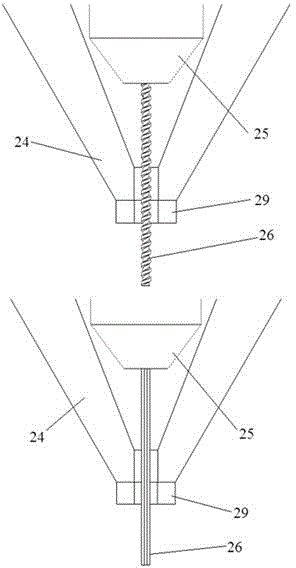

[0033] figure 1 In the EDM-electrolysis combined machining system shown, the machine bed 1, the working tank 2, the workbench 3, the fixture 4, the flushing device support 5, the machine tool spindle 8, the electrolytic machining power supply 10, and the tool electrode 26 constitute the machine tool body . By flushing device 7, tool electrode clamping device 9, first pressure gauge 11 and second pressure gauge 18, first stop valve 12 and second stop valve 22, first check valve 13, second check valve 15 , The third check valve 19 and the fourth check valve 21, multi-stage centrifugal pump 14, clean liquid tank 16, fine filter 17, pressure pump 20, turbid liquid tank 23, flow guiding device 24, clamping guide device 25 , gasket 27, flushing liquid sealing device 29, combined clamping module 30 and pipelines constitute the working fluid circulation system of the machine tool, supplying working fluid for processing and discharging processed products.

[0034]The above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com