Tapping clamp

A wire clamp and clamp handle technology, which is applied in the direction of manufacturing tools, metal processing equipment, thread cutting devices, etc., can solve the problems of time-consuming, labor-intensive, and low efficiency of manual tapping, and achieve the effect of simple thread processing, high efficiency, and avoiding processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

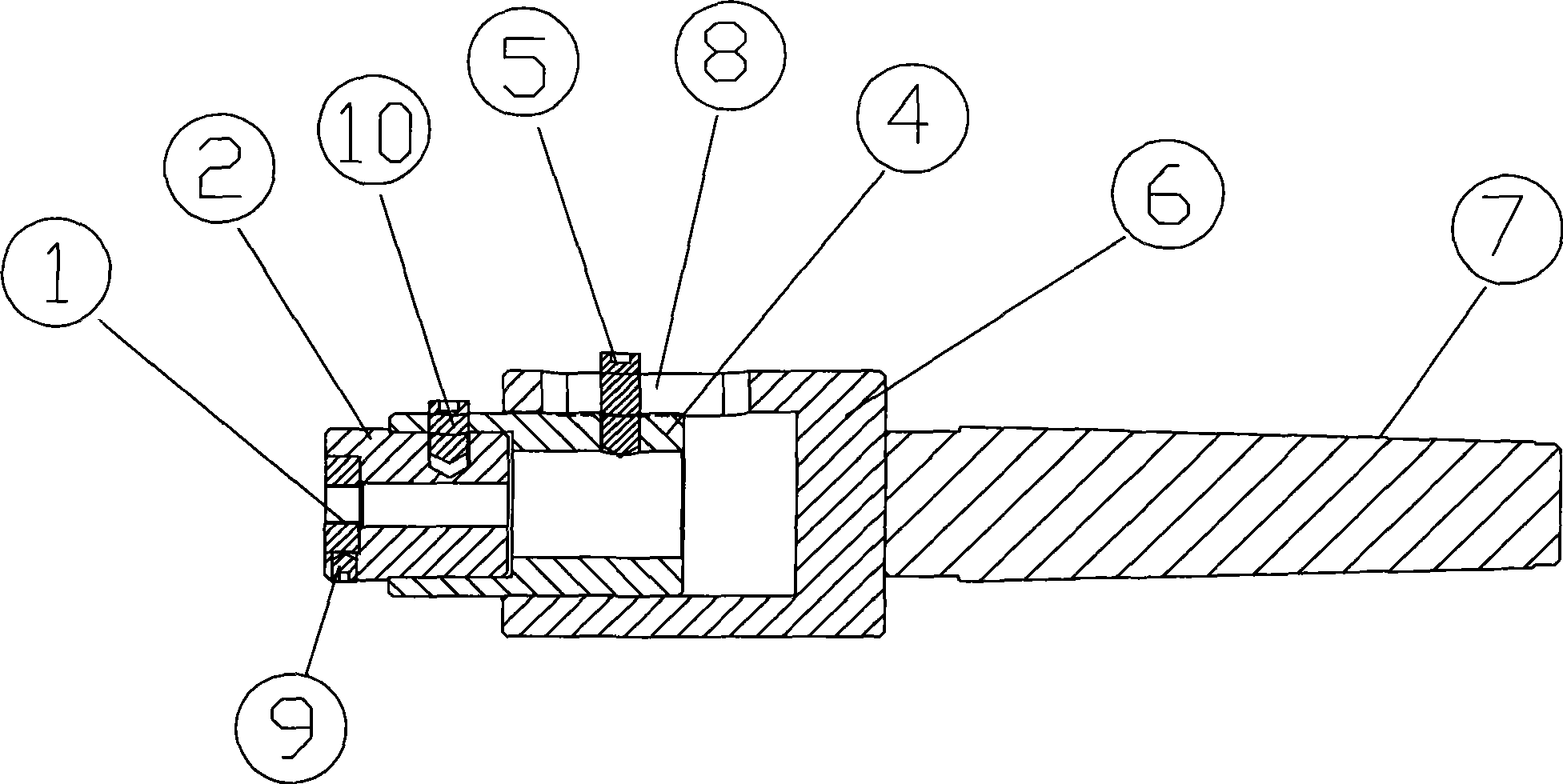

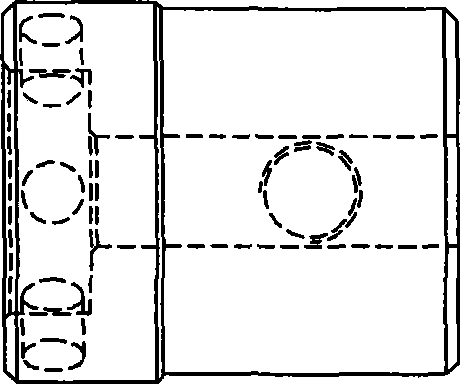

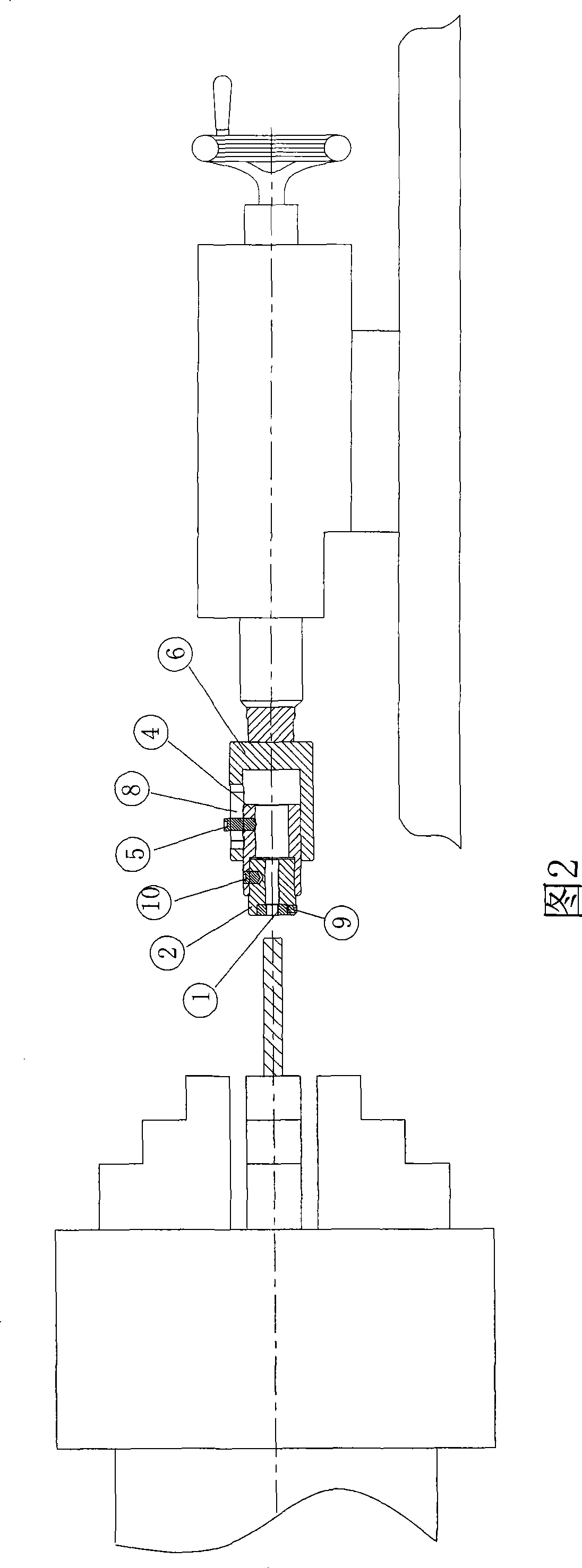

[0012] see Figure 1-3 , the tapping fixture includes a clamping handle 7 for connecting to the thimble of the machine tool, a sleeve 6 welded at the end of the clamping handle, a telescopic sleeve 4 that is axially slidably connected with the sleeve, and connected on the telescopic sleeve The screw tap fixed sleeve 2, the screw tap 1 that is connected with the screw tap fixed sleeve. The clamping handle, the sleeve, the telescopic sleeve, the tap fixing sleeve and the tap are all coaxial.

[0013] On the sleeve wall parallel to the axial direction of the sleeve, a limit groove 8 is opened, and a limit screw hole is opened in the radial direction of the telescopic sleeve, and the guide screw 5 matched with the limit screw hole stretches into the limit groove.

[0014] On the same cross-section of the screw tap fixed sleeve, three adjustment screws 9 extending into the inside of the screw tap fixed sleeve to contact with the outer periphery of the screw tap are radially connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com