Method for controlling welding deformation of box column

A welding deformation and control box technology, which is applied in the field of steel structure welding, can solve the problems of box-shaped columns with different widths and narrow sections, affect the overall quality of components, and have large geometrical size errors, etc., so as to solve the problem of column body section deformation and ensure The effect of improving the internal quality of the weld and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail with the accompanying drawings and specific embodiments.

[0027] A method for controlling welding deformation of a box-shaped column, the method comprising the following steps:

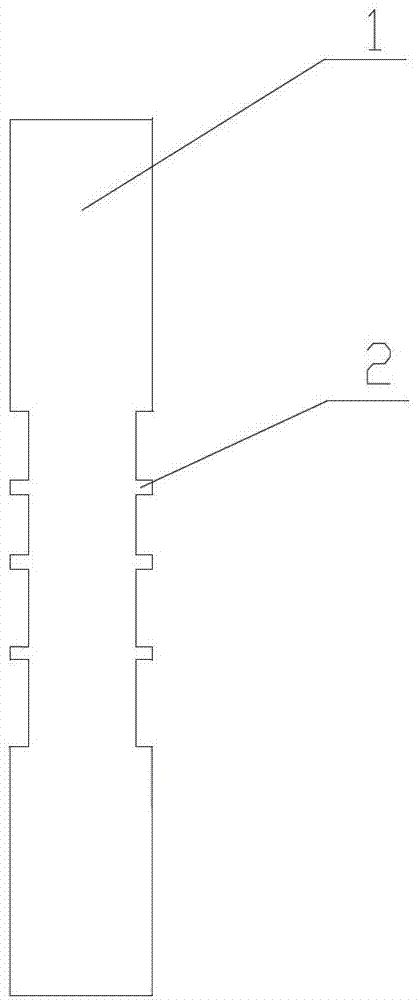

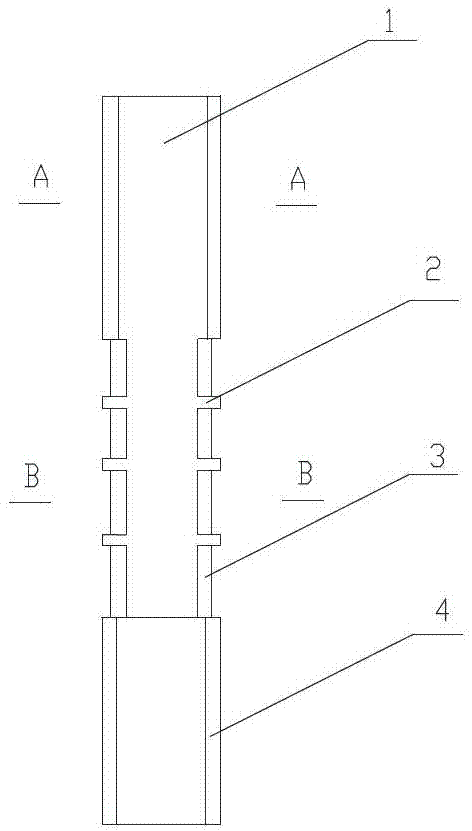

[0028] 1) if figure 1 As shown, three support points 2 are set on the Class I weld area on either side of the symmetrical two sides of the web 1, and the distance between each two support points 2 is 300-400mm, and the support points 2 protrude from the web 1 side edge, and its length along the 1 side edge of the web is 20~40mm;

[0029] 2) if figure 2 As shown, the edges of both sides of the web 1 are processed into grooves;

[0030] 3) After the groove processing is completed, the web 1 and the flange plate 7 are assembled together with the support point 2 as the welding point;

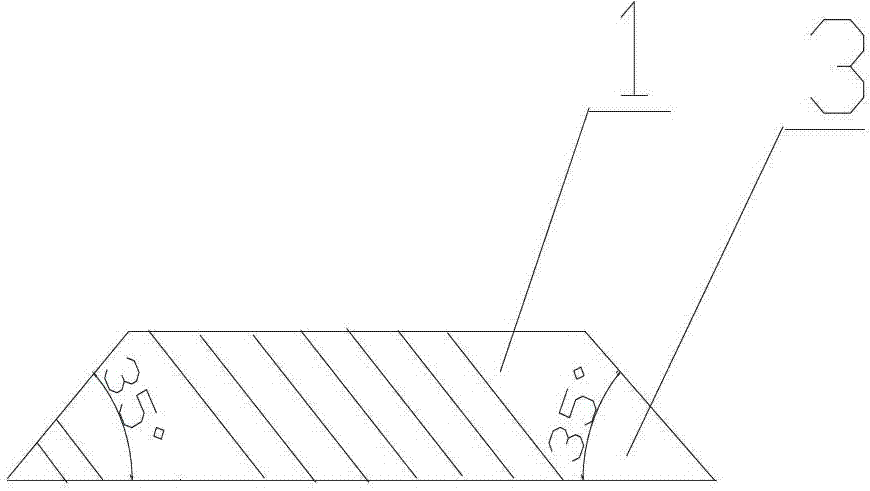

[0031] 4) if Figure 5 As shown, the backing plate is spot welded on the back of weld 6, and the CO 2 Gas shielded welding is used for backing welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com