Full-mechanical drive feeding and sampling device of reactor with high solid concentration

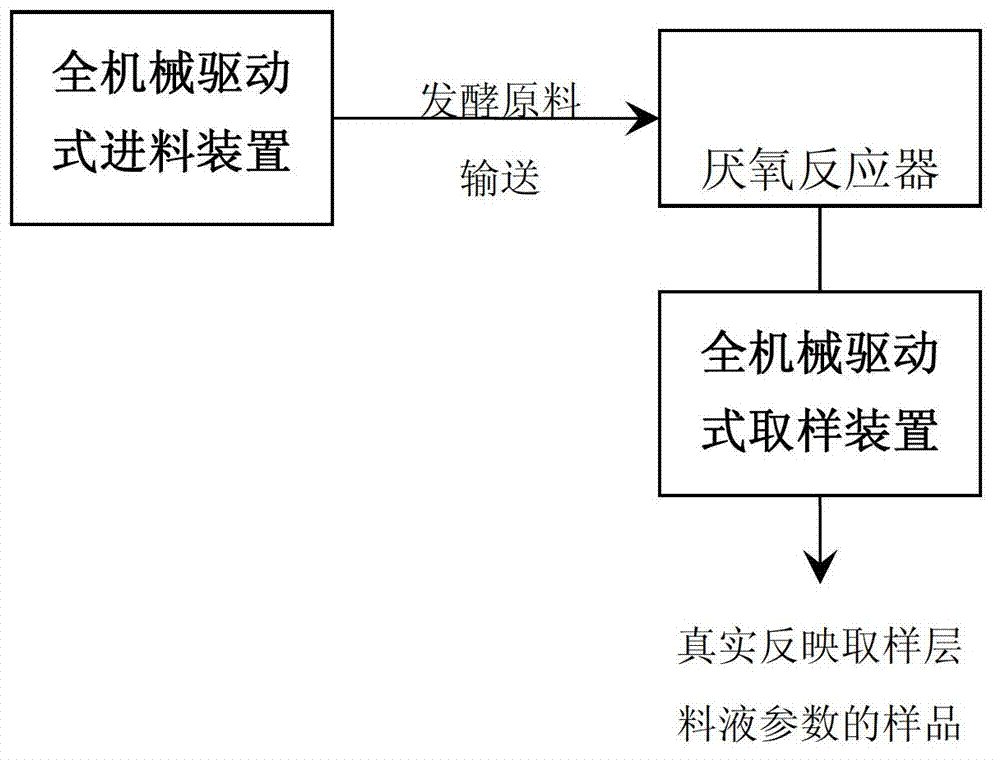

A high solid concentration, driving device technology, applied in the direction of gas production bioreactors, biological material sampling methods, etc., can solve the problems of collecting more liquids, less solids, and not being able to reflect the true composition of the sampling layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

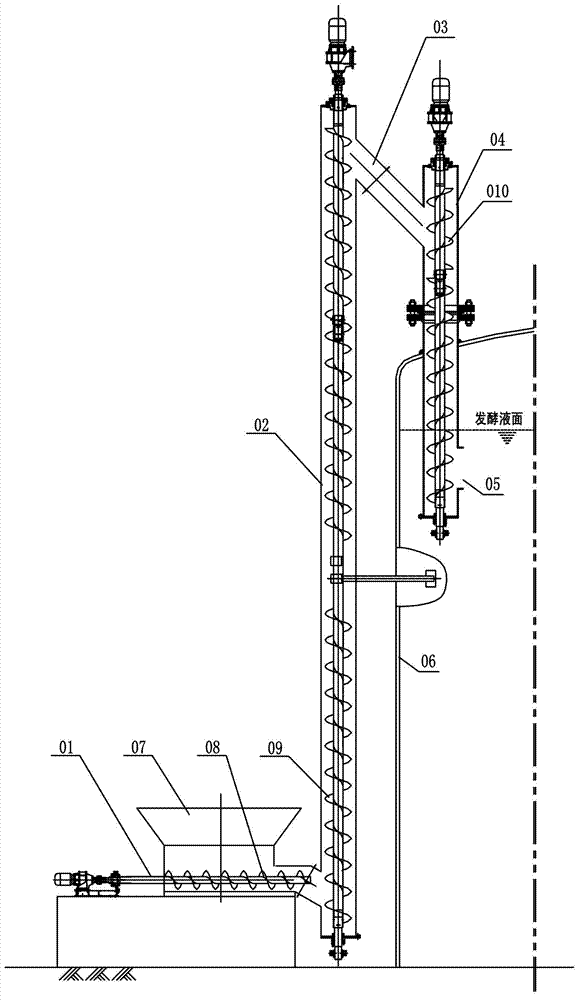

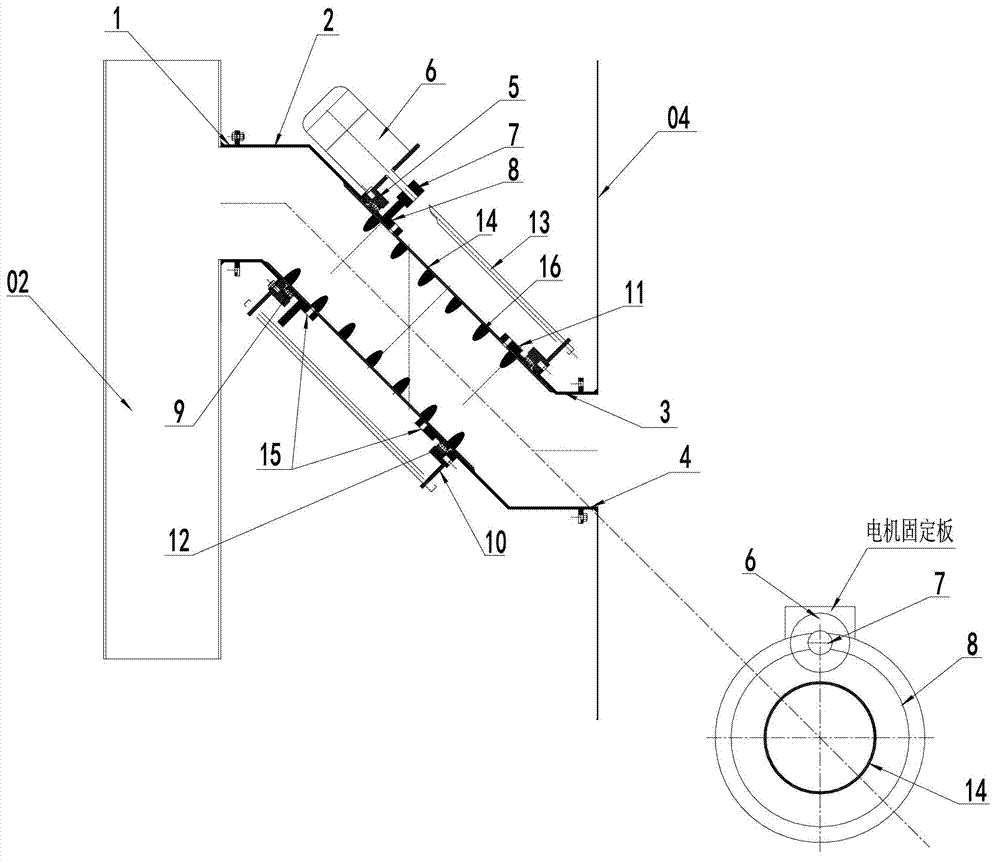

[0027] see figure 1 and figure 2 As mentioned above, the fully mechanically driven feeding and sampling device for the high solid concentration reactor includes a fully mechanically driven feeding device and a fully mechanically driven sampling device. The fully mechanically driven feeding device in this embodiment mainly includes: Horizontal screw feeder 01 for horizontally conveying materials, vertical screw feeder 02 for lifting materials upward, vertical screw feeder 04 for feeding into anaerobic reactor 06, and connecting vertical screw feeder 02 The key mechanical conveying equipment at the upper end and the upper end of the vertical screw feeder 04—the drum screw feeder 03; the fully mechanically driven sampling device is installed on the wall of the anaerobic reactor 06 and the material to be sampled in the anaerobic reactor 06 Liquid layer position, it comprises piston cylinder 17, and piston cylinder 17 part is in anaerobic reactor 06 and has sampling port 18, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com