Single-point fixing adjustable cantilever tripod

A tripod and cantilever technology, applied in the erection/assembly of bridges, connection parts of formwork/formwork/work frame, bridges, etc., can solve the problems of main structure damage, high risk and difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

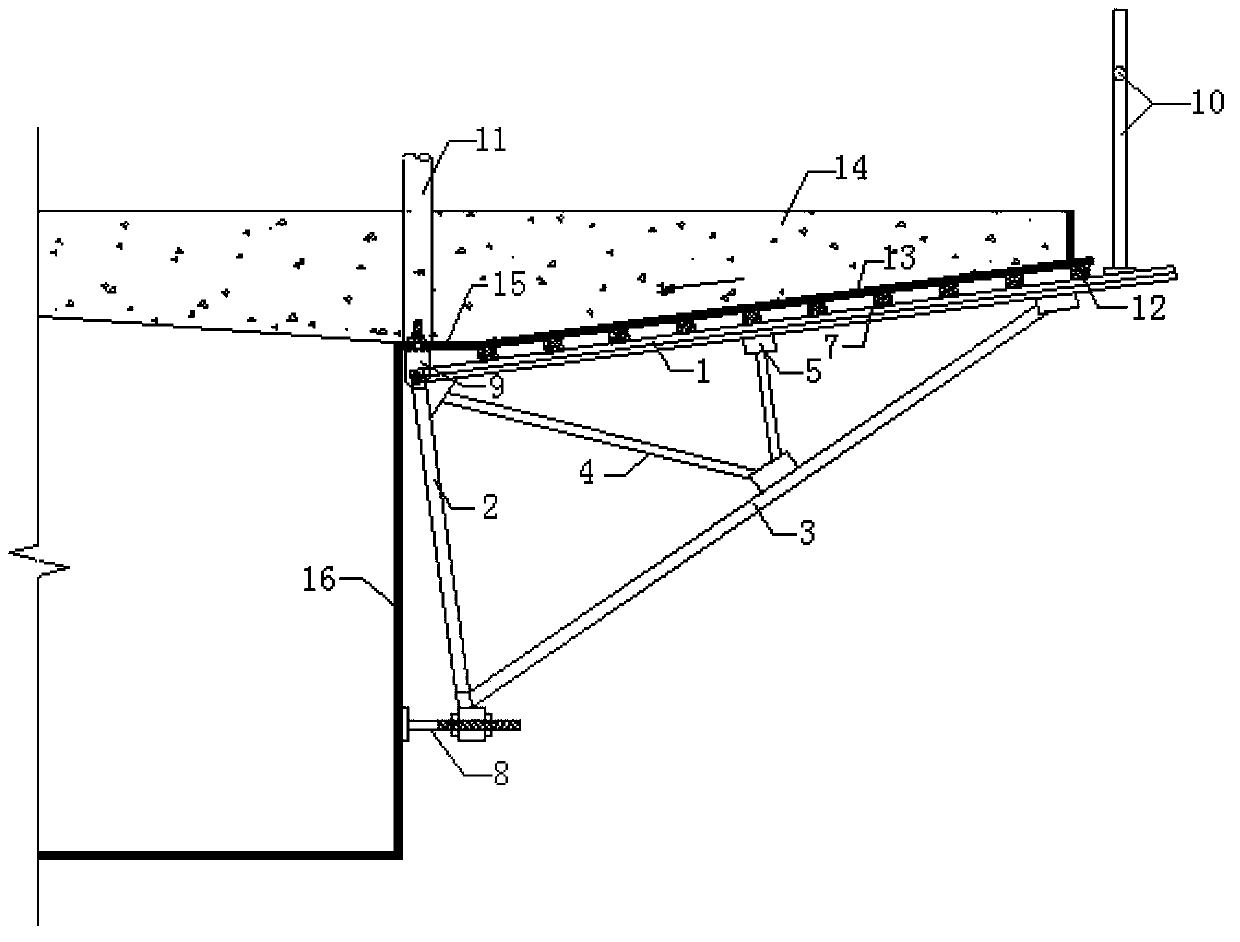

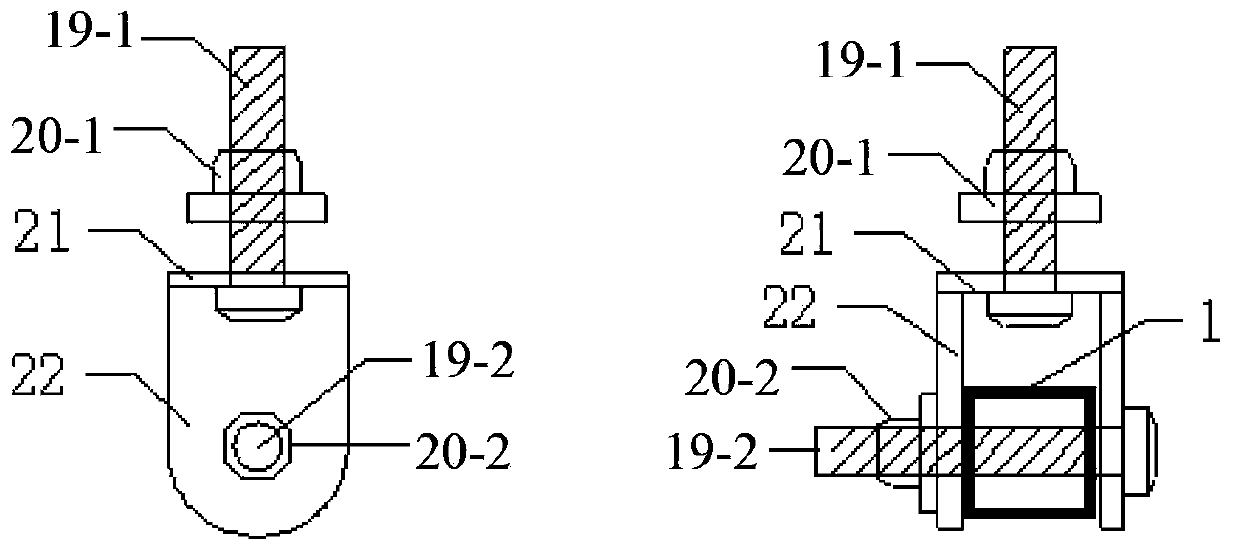

[0024] Such as figure 1 As shown, the single-point fixed adjustable cantilever tripod according to an embodiment of the present invention belongs to a construction temporary support structure, including horizontal bars 1, vertical bars 2, oblique bars 3, web bars 4, connecting plates 5, and stiffeners 6( Image 6 ), baffle plate 7, adjustable bearing 8, rotating bearing 9 and guardrail 10. Among them, horizontal bar 1, vertical bar 2, inclined bar 3, web bar 4, connecting plate 5, stiffener 6, and baffle plate 7 constitute the main structure of the cantilevered tripod, which bears the weight of the newly poured concrete and the load during construction The adjustable support 8 and the rotating support 9 are supports for fixing or supporting the tripod and adjusting the angle of the tripod; the guardrail 10 is used for edge protection during construction to ensure construction safety.

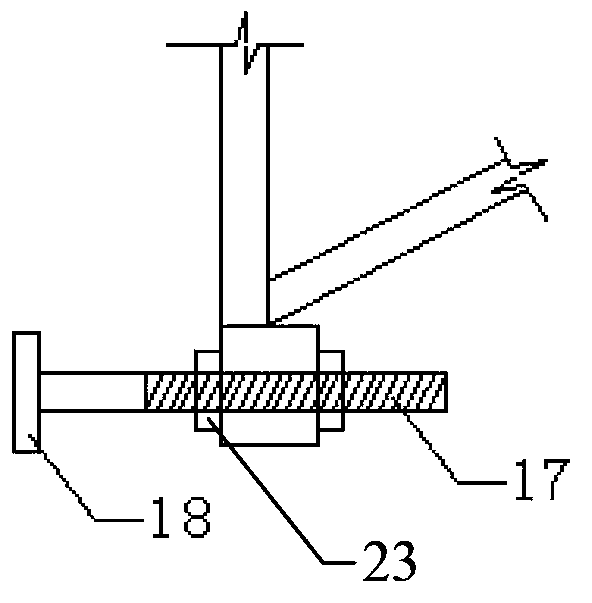

[0025] Such as figure 2 As shown, the adjustable support 8 includes a screw rod 17 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com