Buffer nail assembly tool

A technology for assembling tooling and buffer nails, applied in the field of machinery, can solve the problems of not being able to ensure that the cushioning nails are fully assembled in place, unable to ensure that the cushioning nails are missing, not suitable for mass production, etc., so as to improve production efficiency and economic benefits and improve stability. performance, reducing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

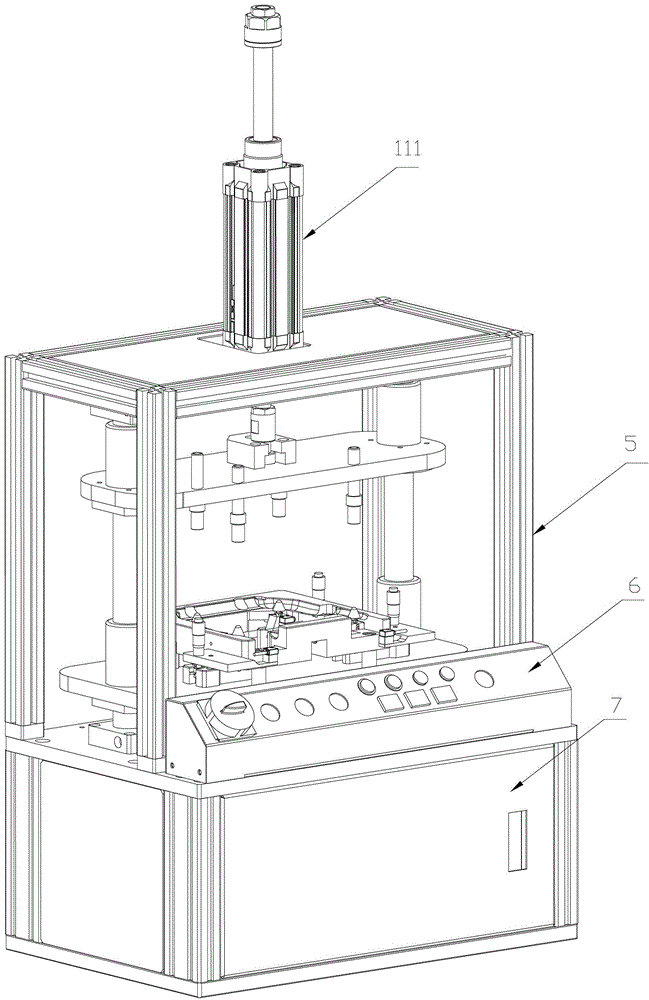

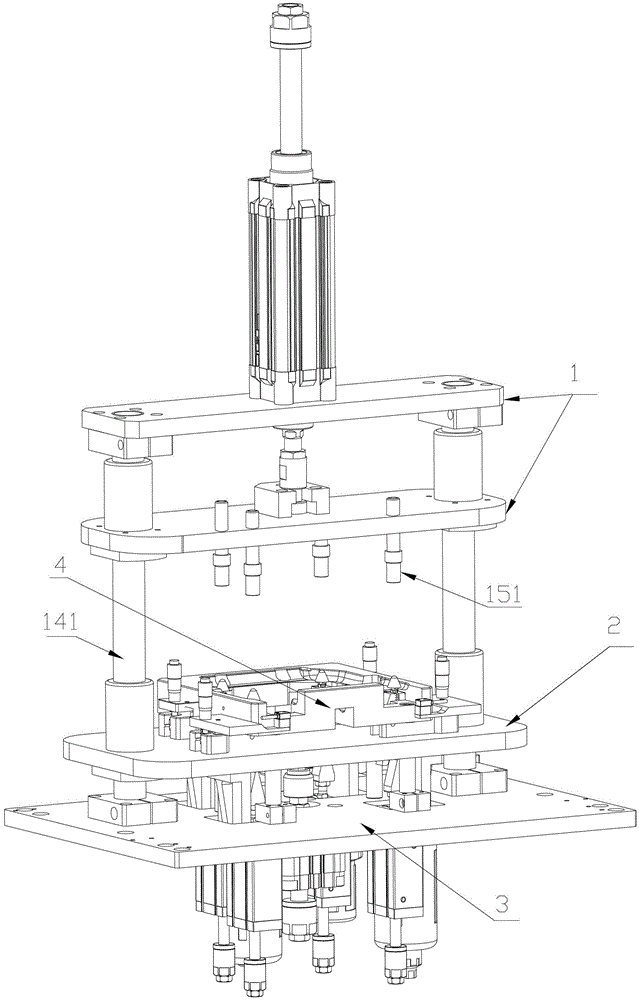

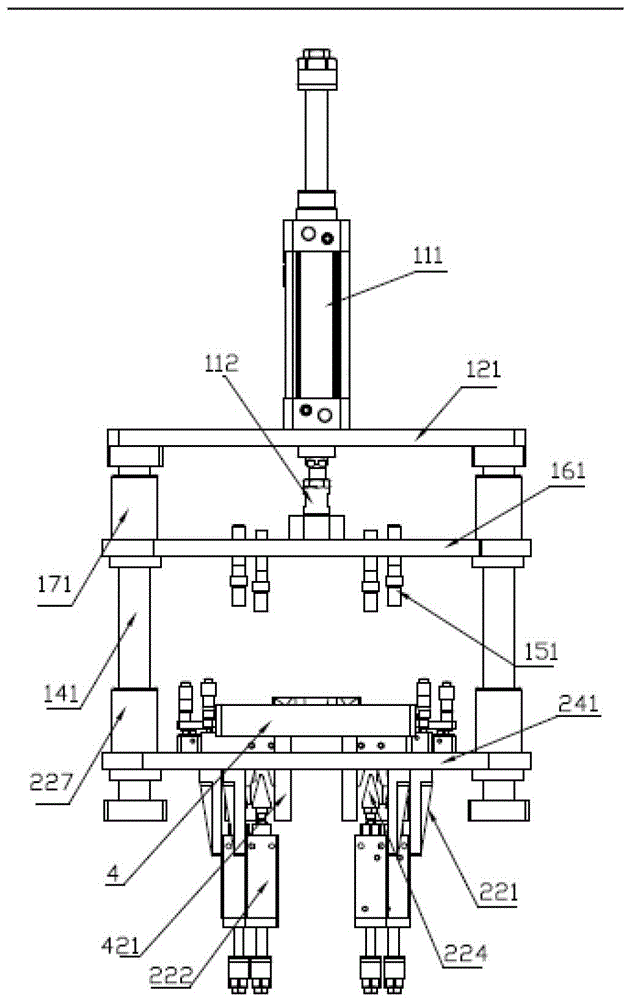

[0026] see figure 1 ~ Figure 9 , The present invention includes a casing positioning tool, a frame, a press-in cylinder module, a clamping cylinder module, and a stretching cylinder module. A guide post 141, along the guide post 141 from top to bottom, are provided with a pressing cylinder module 1, a clamping cylinder module 2, and a stretching cylinder module 3, and a number of indenters 151 are arranged on the lower surface of the pressing cylinder module 1. A plurality of indenters 151 correspond to the positions of the buffer nails to be assembled one-to-one, and a casing positioning tool 4 is provided above the clamping cylinder module 2; Moving up and down, the stretching cylinder module 3 controls the clamping cylinder module 2 to move up and down along the guide post 141 .

[0027] see Figure 4 , the press-in cylinder module 1 described in this example adopts a horizontally placed cylinder fixing plate 121, and the top of the guide post 141 is respectively fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com