Current-conducting rod spring assembling device

A technology of assembling device and conductive rod, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of inability to increase the assembly speed, easy sliding of the spring 8, and inability to assemble smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

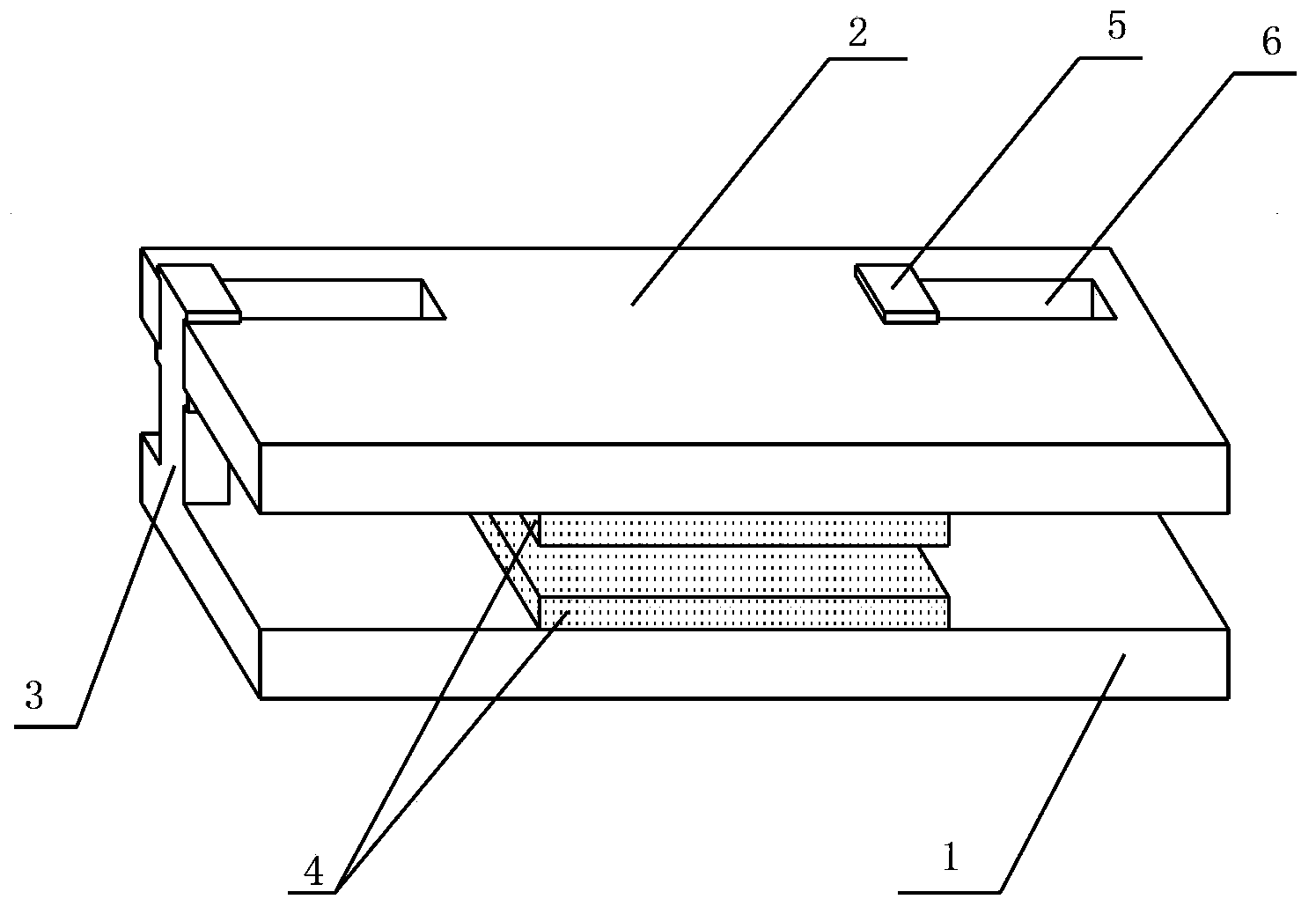

[0010] Such as figure 2 as shown, figure 2 It is a structural schematic diagram of a conductive rod spring assembly device proposed by the present invention.

[0011] refer to figure 2 , a conductive rod spring assembly device proposed by the present invention is used to fit the spring on the conductive rod, including a first plate 1 and a second plate 2; two sides of the first plate 1 are provided with sliders 3, so The opposite position on the second plate 2 is provided with a slide groove 6, the first plate 1 can slide relative to the second plate 2, and the corresponding position on the opposite surface of the first plate 1 and the second plate 2 A soft layer 4 is provided, and the areas of the soft layer 4 on the first board 1 and the second board 2 are equal in size.

[0012] In this embodiment, one end of the slider 3 is fixedly connected to the first plate 1, and the other end is provided with a baffle plate 5 that can prevent falling off from the chute 6, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com