Method for mounting submerged buoy in ultra-deep water

An installation method and ultra-deep water technology, applied in anchoring arrangement, transportation and packaging, ship parts, etc., can solve the problems of consuming a lot of man-hours and increasing the installation cost of buoys, and achieve the effect of easy operation, reduction of operation difficulty and cost avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

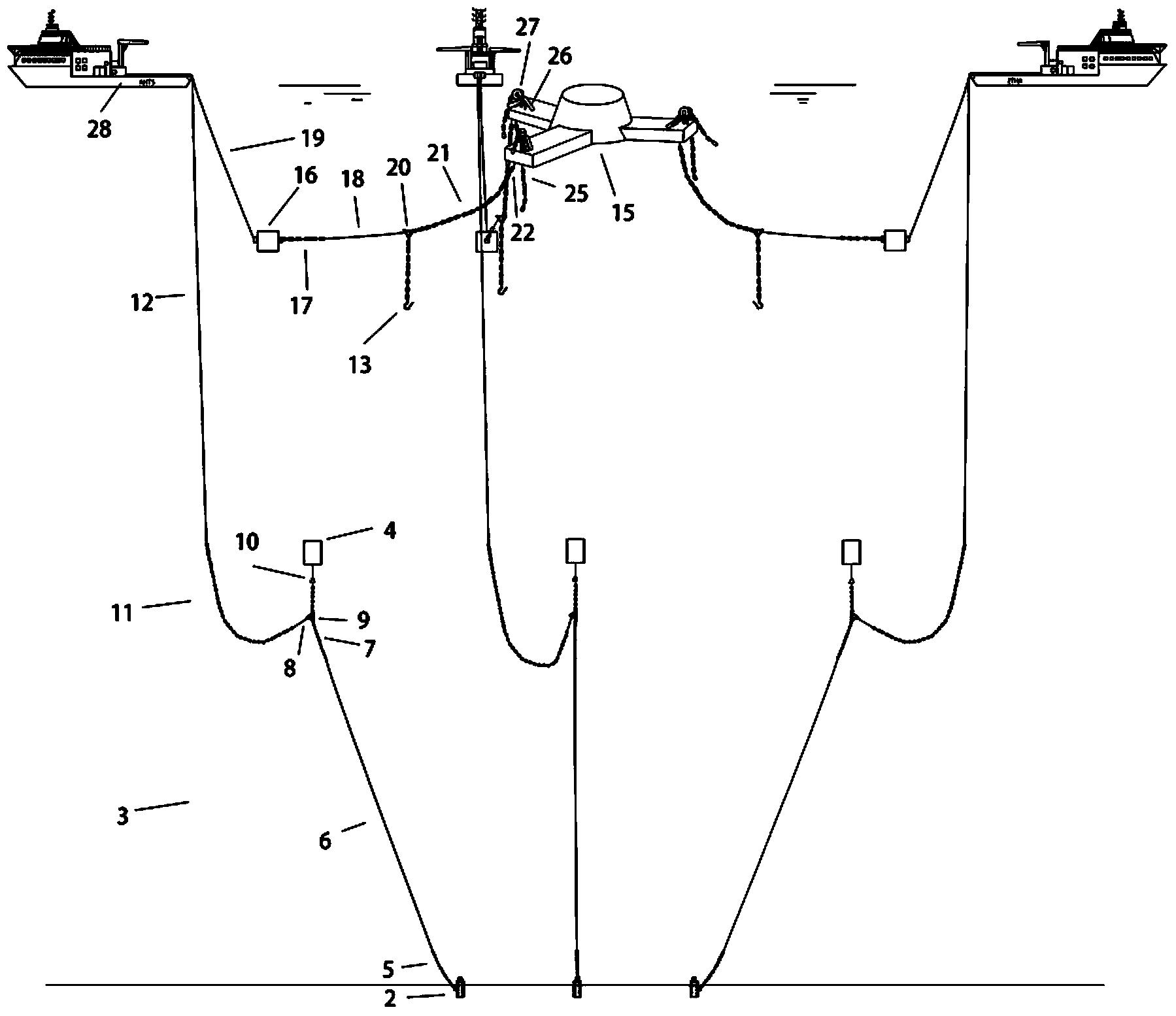

[0046] The present invention will be further described below in conjunction with the accompanying drawings. The invention is illustrated by way of example of the installation of a buoy with three anchor leg connection points.

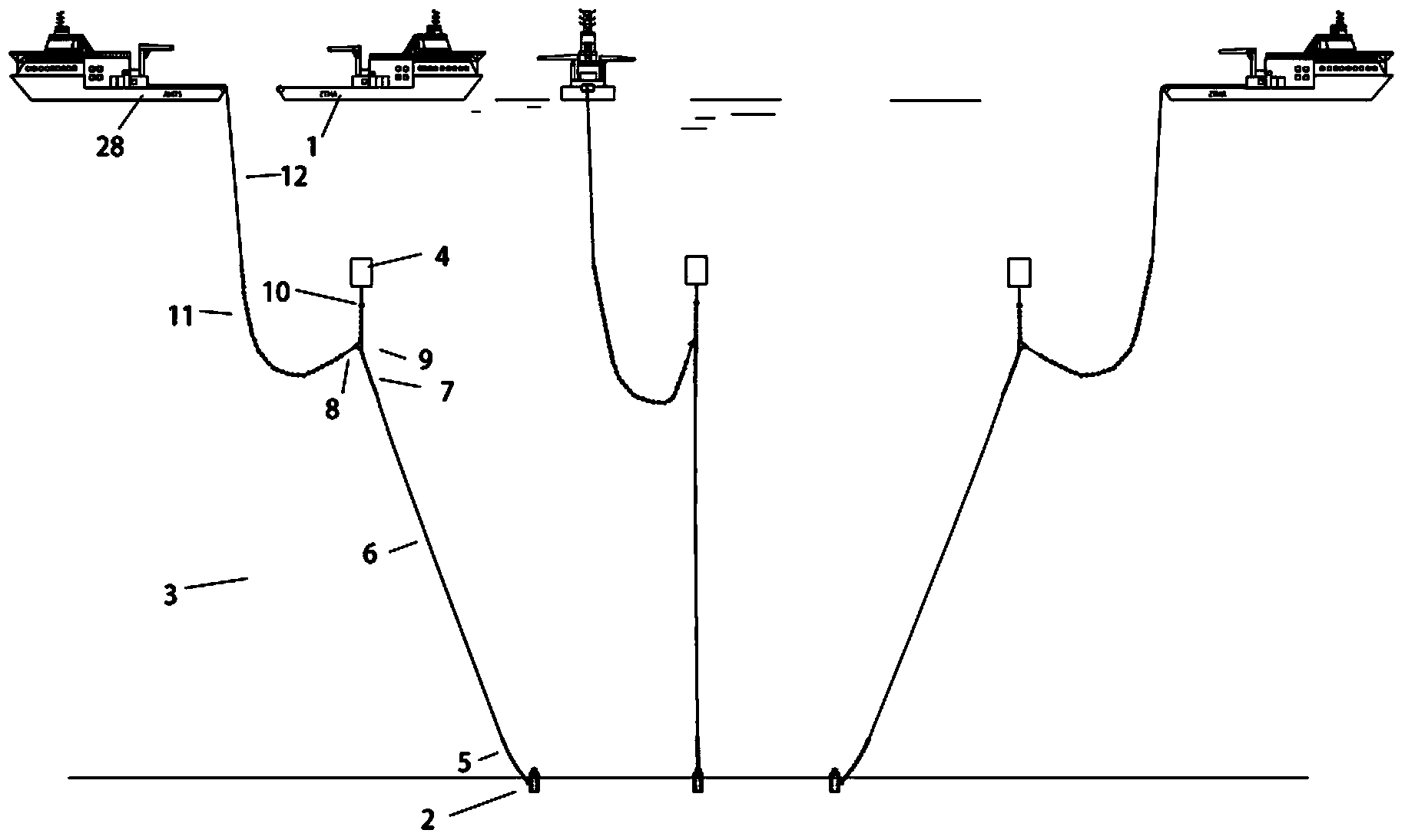

[0047] Such as figure 1 As shown, the synchronous installation of the deepwater anchor 2 and the anchor leg 3 is completed through the cooperation of the workboat A1 and the workboat B28. The anchor leg 3 (including the bottom anchor chain section 5, the anchor cable 6, and part of the top anchor chain section A7) is kept tensioned in the water under the action of the auxiliary buoy 4 and the chain section A11, and is inclined at a certain angle so that the buckle 10 is in the water. A certain position is maintained in the water to facilitate connection with the hook 13 and to prevent interference between different anchor legs.

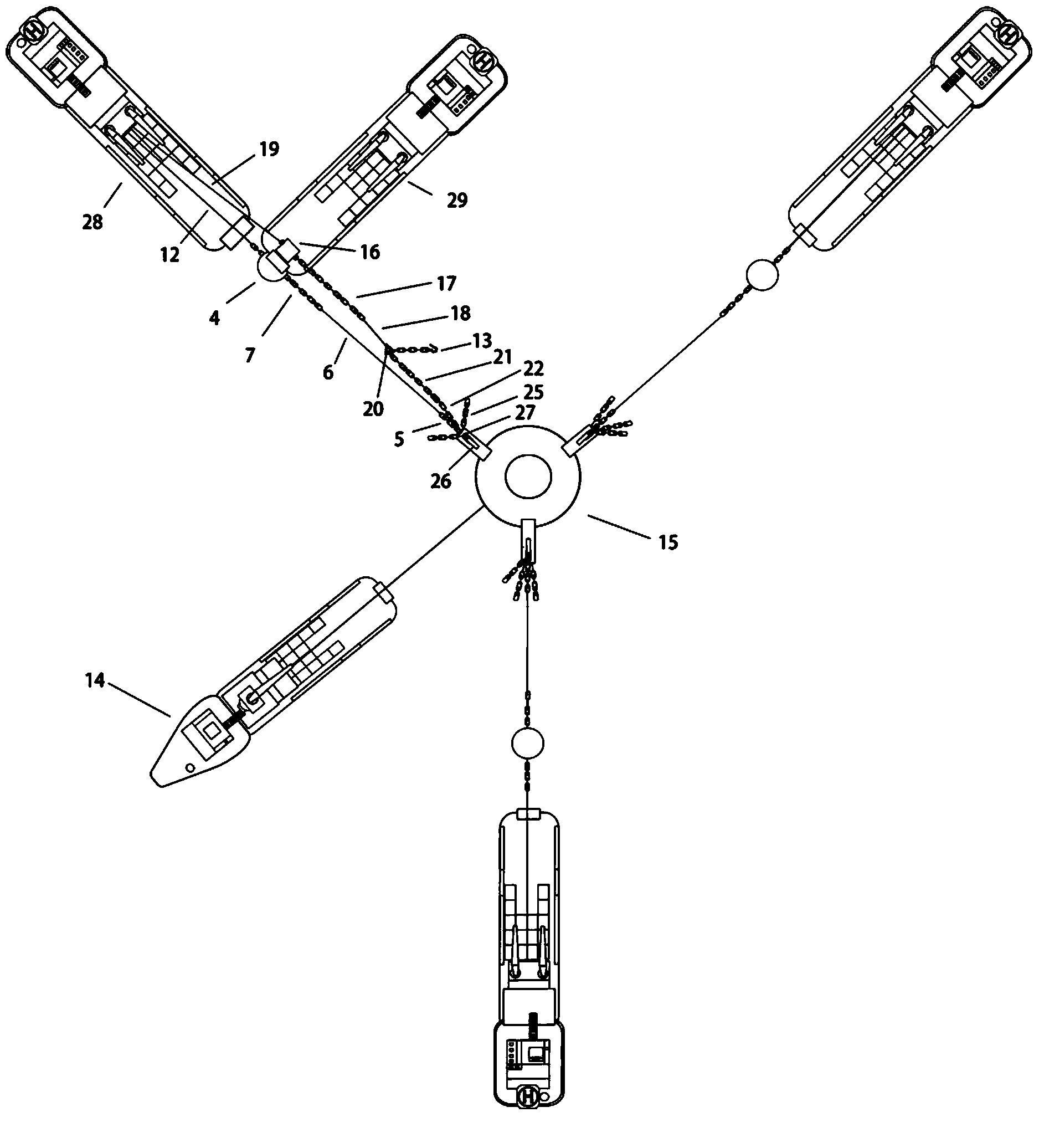

[0048] Such as figure 2As shown, with the assistance of another workboat C29, three groups of ballast systems are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com