Full-automatic garbage can

A garbage can, fully automatic technology, applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve problems such as physical health threats, garbage overflow, inconvenience in using garbage cans, etc., to avoid environmental pollution and solve the effect of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

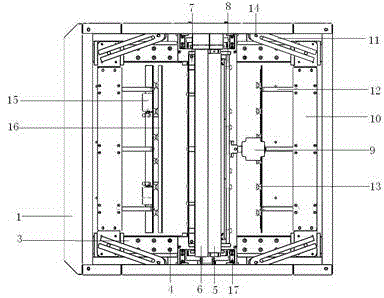

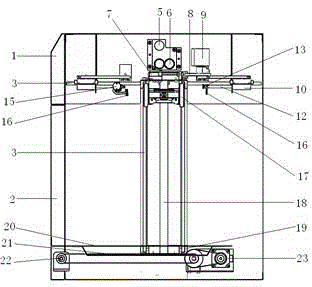

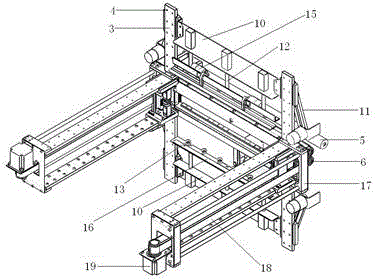

[0022] Example 1: Such as figure 1 , figure 2 , image 3 As shown, a fully automatic trash bin includes a box body 1 and a box door 2. It is characterized in that two slide rails 3 are arranged on the upper part of the box body 1, a bag feeding device is arranged above the slide rail 3, and a bag feeding device is arranged below the bag feeding device. A bag cutting device is provided, the bag cutting device is arranged on the slide rail 3, a bag opening device is arranged under the bag cutting device, a bag sealing device is arranged under the bag opening device, a bag pulling device is arranged under the bag sealing device, and the bag pulling device is arranged Below the slide rail 3, a sliding door device is provided in the lower part of the box 1. The two slide rails 3 are T-shaped and are arranged on both sides of the box 1 in parallel. The slide rail 3 is provided with two rows of circular screw holes 4 for bag delivery. The device is composed of a winding frame 5 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com