Dispersible fully-degradable spunlace nonwoven fabric, preparation method and production line

A technology of spunlace non-woven fabrics and production methods, which is applied in the direction of textiles and papermaking, needle punching machines, non-woven fabrics, etc., which can solve the problems of weak non-woven fabrics, secondary pollution of the environment, and failure to release features. Achieve the effect of promoting mutual entanglement, avoiding secondary pollution, and good flushability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

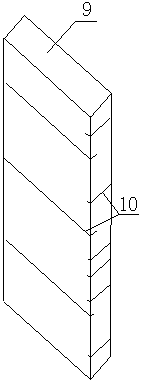

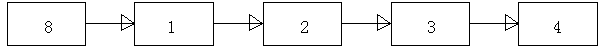

[0017] Embodiment 1: with reference to attached figure 1 and 2 . A flushable and fully degradable spunlaced nonwoven fabric, which is composed of 35-50% zigzag flat viscose fiber 9 and 65-50% wood pulp. The zigzag flat viscose fiber 9 is a deformed viscose fiber 10 after being spun and cut. The zigzag flat viscose fiber (deformed viscose fiber 10) has a length of 5-20 mm. Of the 35-50% zigzag flat viscose fibers (deformed viscose fibers 10), 70-80% have a fiber length greater than 10 mm and less than or equal to 20 mm, and 70-80% have a fiber length greater than or equal to 5 mm and less than or equal to 10 mm. 20-30%. The length of the wood pulp fiber is 1-5mm. Among the 65-50% wood pulp, 20-30% of the fiber length is greater than or equal to 1mm and less than or equal to 3mm, and 80-70% of the fiber length is greater than 3mm and less than or equal to 5mm. The technical indicators of the fully degradable spunlace non-woven fabric that can be washed away are as follows:...

Embodiment 1-1

[0020] Example 1-1: On the basis of Example 1, a fully degradable spunlaced nonwoven fabric that can be flushed is composed of 35% zigzag flat viscose fiber 9 and 65% wood pulp. The zigzag flat viscose fiber 9 is a deformed viscose fiber 10 after being cut off (see figure 1 mid-swing tangent). Among the 35-50% zigzag flat deformed viscose fibers, 70-80% have a fiber length greater than 10 mm and less than or equal to 20 mm, and 20-30% have a fiber length greater than or equal to 5 mm and less than or equal to 10 mm. Among the 65-50% wood pulp, 20% of the fiber length is greater than or equal to 1mm and less than or equal to 3mm, and 80% of the fiber length is greater than 3mm and less than or equal to 5mm.

Embodiment 1-2

[0021] Example 1-2: On the basis of Example 1, a fully degradable spunlaced nonwoven fabric that can be flushed is composed of 50% zigzag flat viscose fiber 9 and 50% wood pulp. The zigzag flat viscose fiber 9 is a deformed viscose fiber 10 after being spun and cut. Among the 35-50% zigzag flat deformed viscose fibers, 70-80% have a fiber length greater than 10 mm and less than or equal to 20 mm, and 20-30% have a fiber length greater than or equal to 5 mm and less than or equal to 10 mm. Among the 65-50% wood pulp, 30% of the fiber length is greater than or equal to 1mm and less than or equal to 3mm, and 70% of the fiber length is greater than 3mm and less than or equal to 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com