Oil return structure for cooling fan

A cooling fan and oil return tank technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of reducing the service life of cooling fans, polluting the internal structure of cooling fans, condensation and other problems, to reduce noise and friction, improve service life, and ensure cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

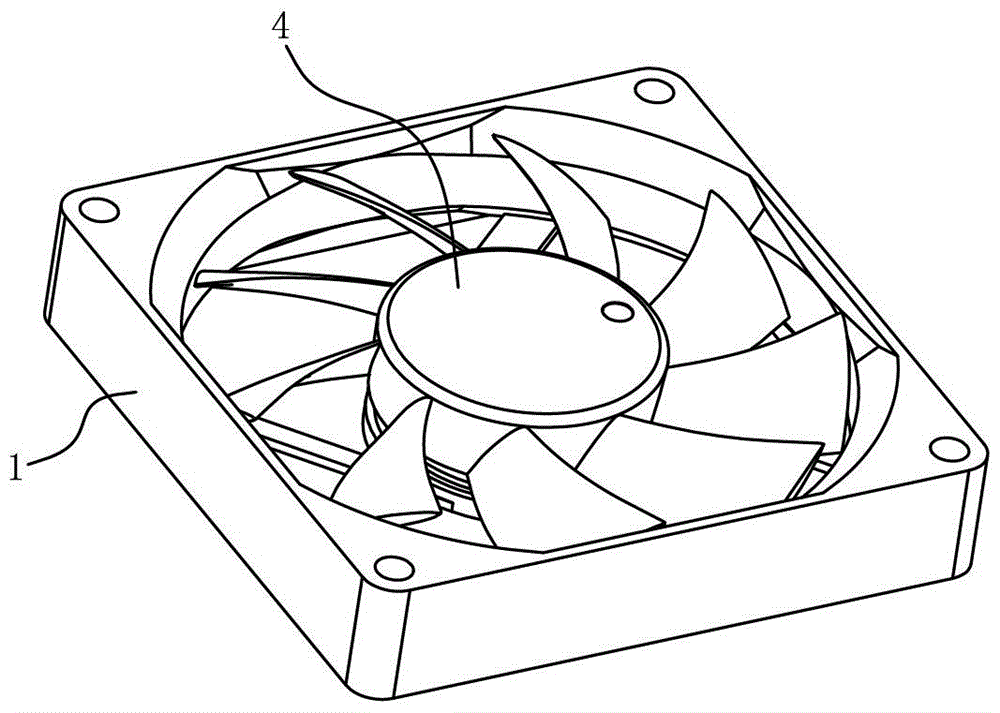

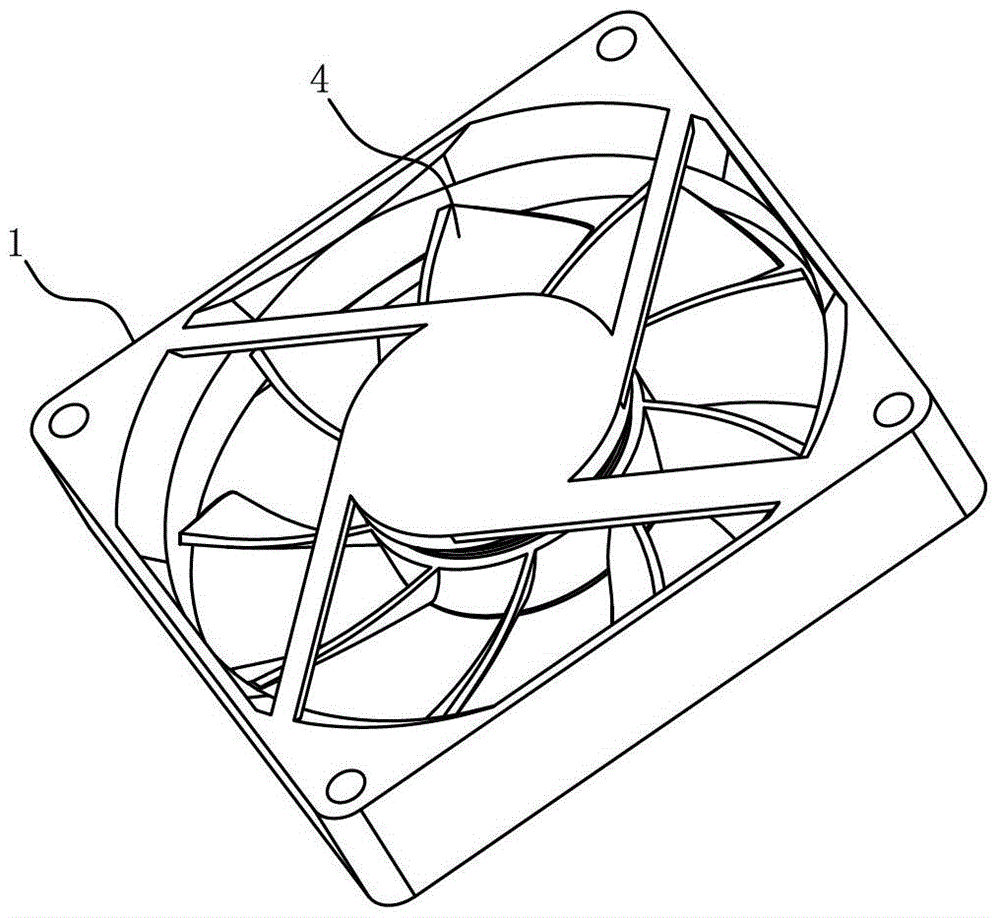

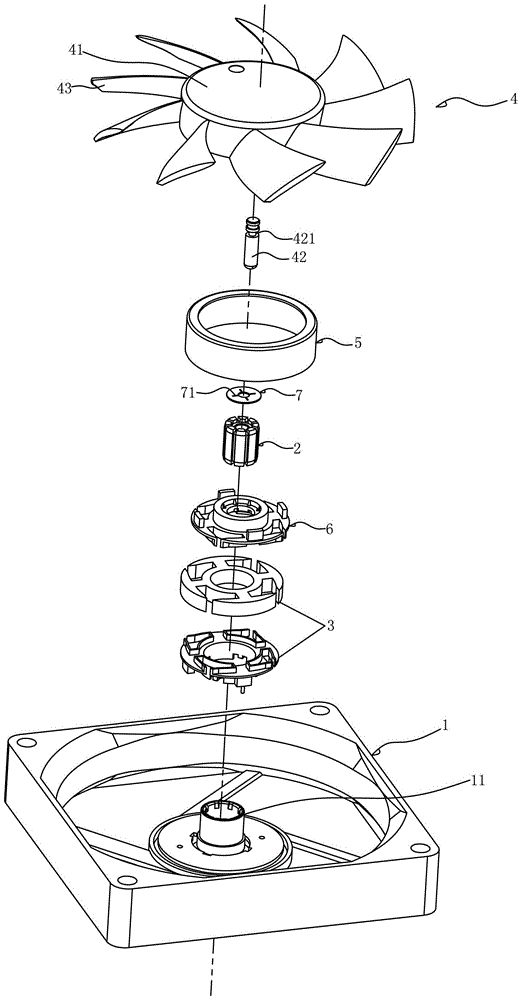

[0032] see Figure 1-11 As shown, an oil return structure for a cooling fan includes: a base frame 1, a bearing 2 mounted on the base frame 1, a stator 3, a fan blade 4, and a rotor 5 matched with the fan blade 4, wherein the rotor 5 is located at The periphery of the stator 3 , wherein the fan blade 4 is arranged on the base frame 1 through a rotating shaft 42 in cooperation with the bearing 2 .

[0033] The middle part of the base frame 1 is formed with an upwardly protruding and hollow center column 11 , and the bearing 2 is installed in the center column 11 . The upper end surface of the central column 11 is provided with several fourth oil return grooves 111, and the bottom of the fourth oil return grooves 111 is an inclined surface, which is convenient for the return of lubricating grease. An oil return frame 6 and an insulating ring piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com