Detection method for parallelism and coaxiality of flanges at two ends of pylon

A detection method and parallelism technology, which is applied in the field of parallelism and coaxiality detection of flanges at both ends of the tower section, can solve problems such as poor precision, large influence on workshop production process, long adjustment time, etc., and achieve the goal of reducing human factors Effects of interference, mitigation of site turnover issues, and simple detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

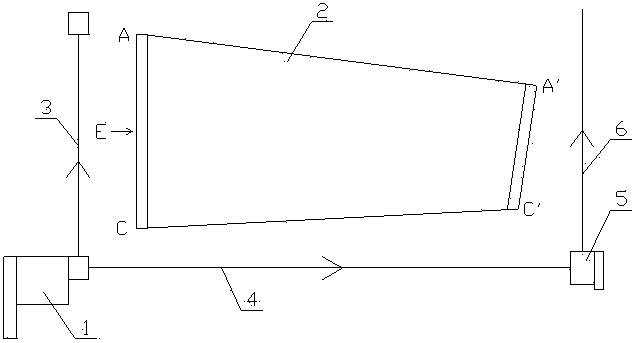

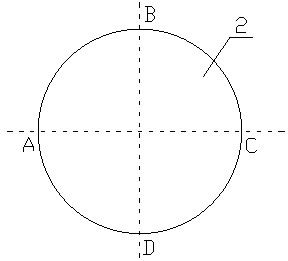

[0020] Such as figure 1 with figure 2 An embodiment of the method for detecting the parallelism and coaxiality of the flanges at both ends of the tower section of the present invention is shown, which includes the following steps:

[0021] A. Measuring parallelism:

[0022] a. Place the laser transmitter 1 on the large diameter end of the tower section 2, the large diameter end is the proximal end, that is, the small diameter end is the distal end;

[0023] b. Adjust the first laser beam 3 emitted by the laser transmitter 1 so that the rotating surface of the first laser beam 3 is parallel to the proximal flange surface. Specifically, the three-point leveling method is used: first use the tripod of the laser transmitter for rough adjustment , To ensure that the first laser beam can hit the target frame of the three reference points, and then use the coarse and fine adjustment screws on the laser transmitter to make fine adjustments, and adjust the height difference of the three poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com