Engineering optimization method for adjusting composite material layering

A composite material and engineering optimization technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of focusing on one thing and losing another, and achieve the effect of reducing the probability of modification, reducing the amount of data, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Embodiment: The present invention comprehensively analyzes the structural features of the composite material layup storehouse and composite material parts when carrying out multi-thickness area composite material laminate layup design, so as to obtain the layup that meets the professional requirements such as structure, strength, and manufacturing. layer design results.

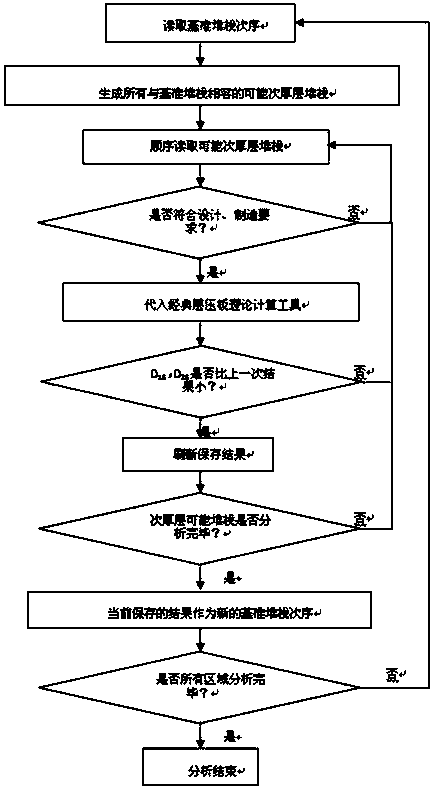

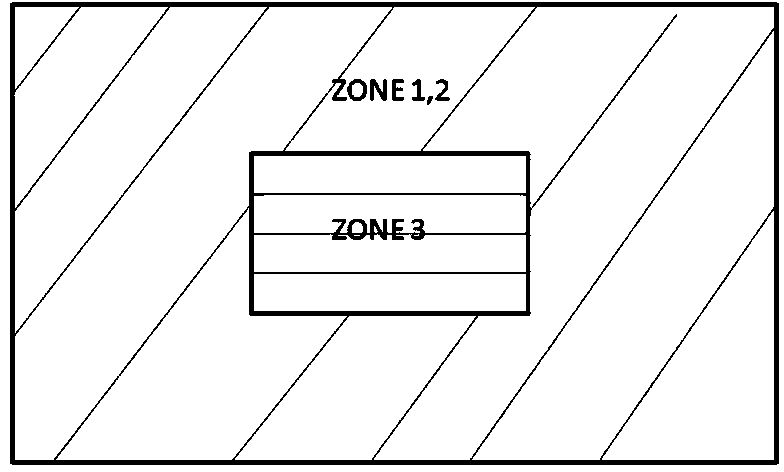

[0056]In order to realize the above-mentioned technical solution, the present invention includes a ply ratio adjustment and optimization method and a directional ply stack adjustment method. The ply ratio adjustment and optimization method is based on the initial ply data of the current structure of the composite material laminate part input by design, including The division of the ply area, the total number of ply layers in each area, and the number of ply layers at each angle in each area, with the minimum change in the ply angle ratio difference AML index of the overall structure as the optimization ...

example

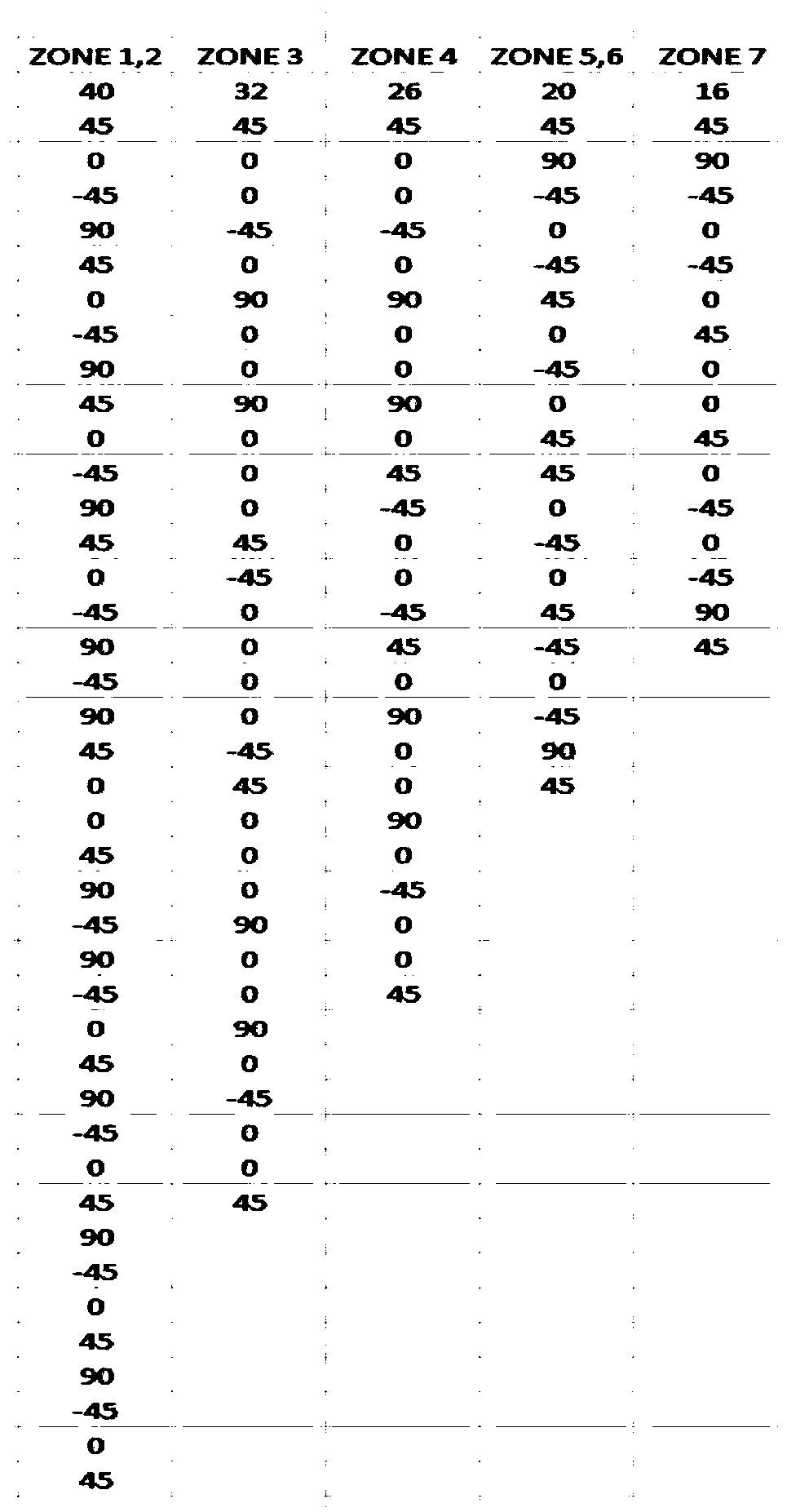

[0122] According to the practice of an international civil aircraft project, the original lay-up design scheme shown in Figure 7(a), the result of the optimization method of the present invention, and the result of manual adjustment in the real product are compared as shown in Figure 7(b); Figure 8 Shown is a comparison of the safety margins of the two. The results show that the two have the same level of safety margin, but the work efficiency is increased by 10 times, and the designer does not need a high level of experience.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com