Submersible motor with easily disassembled angular contact ball bearing

A technology for angular contact ball bearings and submersible motors, which is applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as affecting work efficiency, increasing costs, and difficulty in disassembly, and achieves the effect of reducing losses, easy disassembly, and solving maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

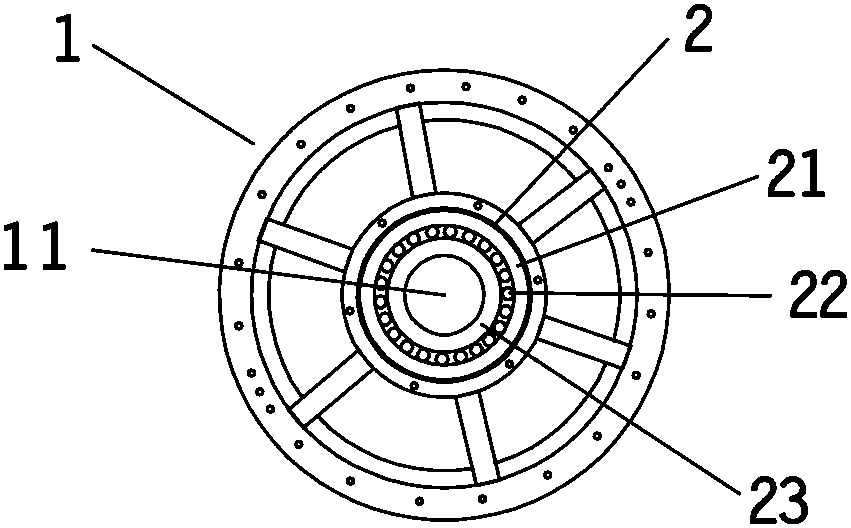

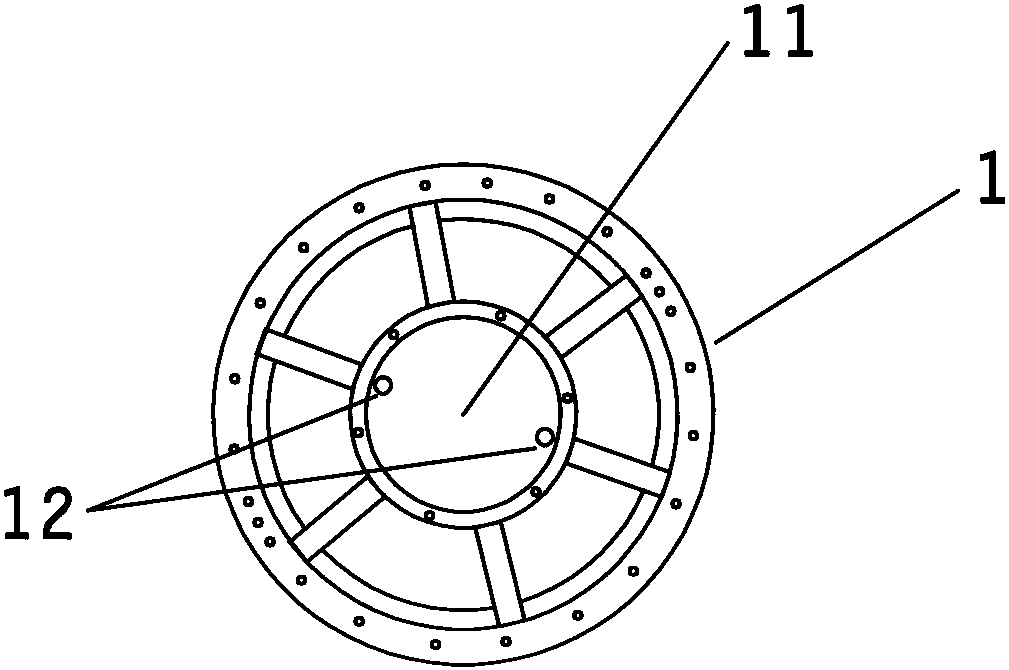

[0017] Embodiment 1: A submersible motor with easy-to-remove angular contact ball bearings, including a bearing support 1 and an angular contact ball bearing 2, the bearing support 1 includes a bearing chamber 11, and the angular contact ball bearing 2 is located in the bearing chamber 11 Inside, the angular contact ball bearing 2 includes an outer ring 21, balls 22, and an inner ring 23. There are at least two screw holes 12 at the bottom of the bearing support body 1, and the screw holes 12 are located at the corresponding angular contact of the bearing support body 1. There are 21 places on the outer ring of the ball bearing 2, which are symmetrically distributed around the axis.

[0018] When the angular contact ball bearing 2 needs to be disassembled, the outer ring 21 of the angular contact ball bearing 2 can be pushed out of the bearing chamber 11 by screwing a sufficiently long bolt into the screw hole 12 of the bearing support body 1 .

Embodiment 2

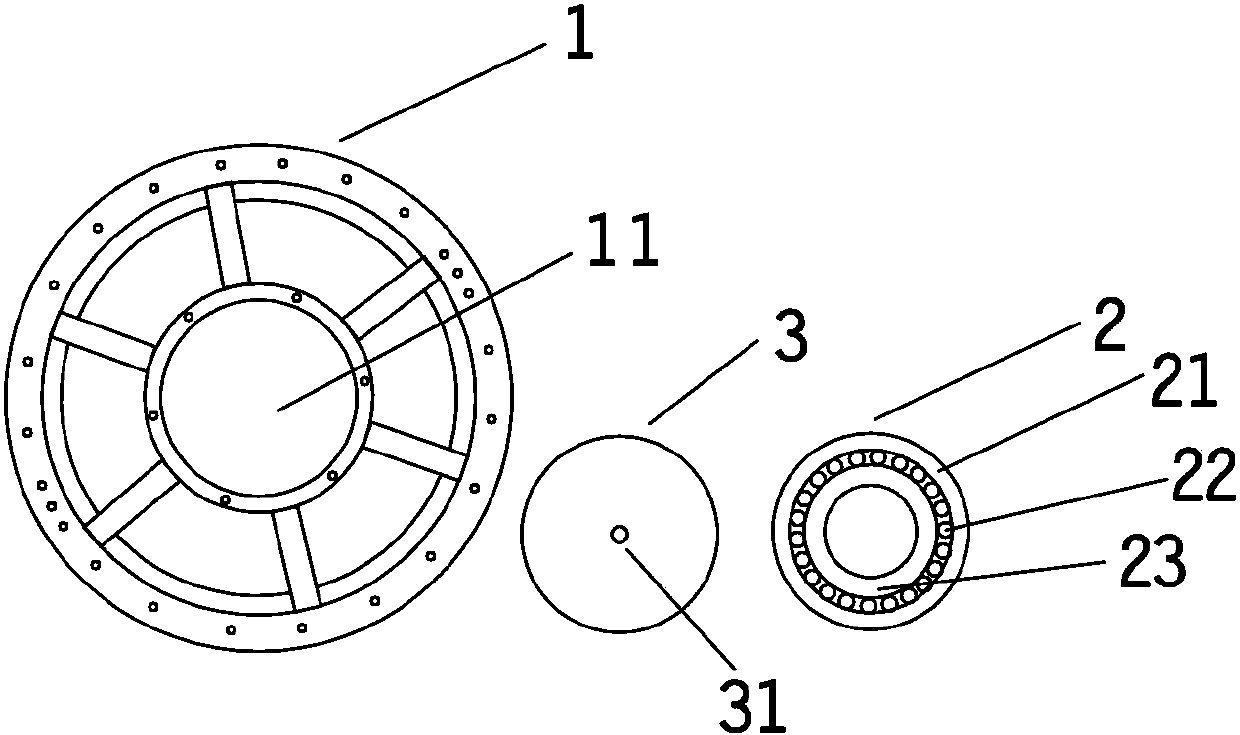

[0019] Embodiment 2: A submersible motor with easy-to-remove angular contact ball bearings, including a bearing support 1 and an angular contact ball bearing 2, the bearing support 1 includes a bearing chamber 11, and the angular contact ball bearing 2 is located in the bearing chamber 11 Inside, the angular contact ball bearing 2 includes an outer ring 21, balls 22, and an inner ring 23. A backing plate 3 is installed between the angular contact ball bearing 2 and the bottom of the bearing chamber 11, and the backing plate 3 is provided with 1 screw hole 31 , the screw hole 31 is located at the center point of the backing plate 3 .

[0020] Another improvement of the technical solution is: the backing plate 3 is provided with at least two screw holes 31, and the screw holes 31 are located on the backing plate 3 corresponding to the inner ring 23 of the angular contact ball bearing 2, and are distributed axially symmetrically.

[0021] When it is necessary to disassemble the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com