Expansion shaft device used for installing refrigeration compressor motor

A refrigeration compressor and shaft expansion technology, which is applied in the field of refrigeration compressors, can solve the problems of reduced production efficiency, high parts processing costs, and high parts scrap rate, and achieve the effects of improving installation speed, ensuring installation accuracy, and ensuring coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

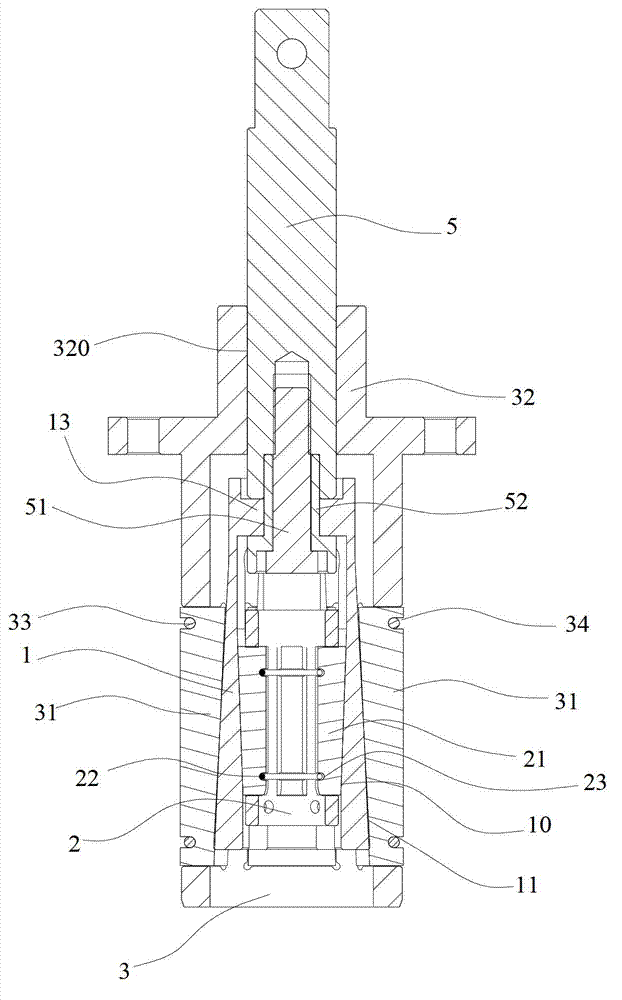

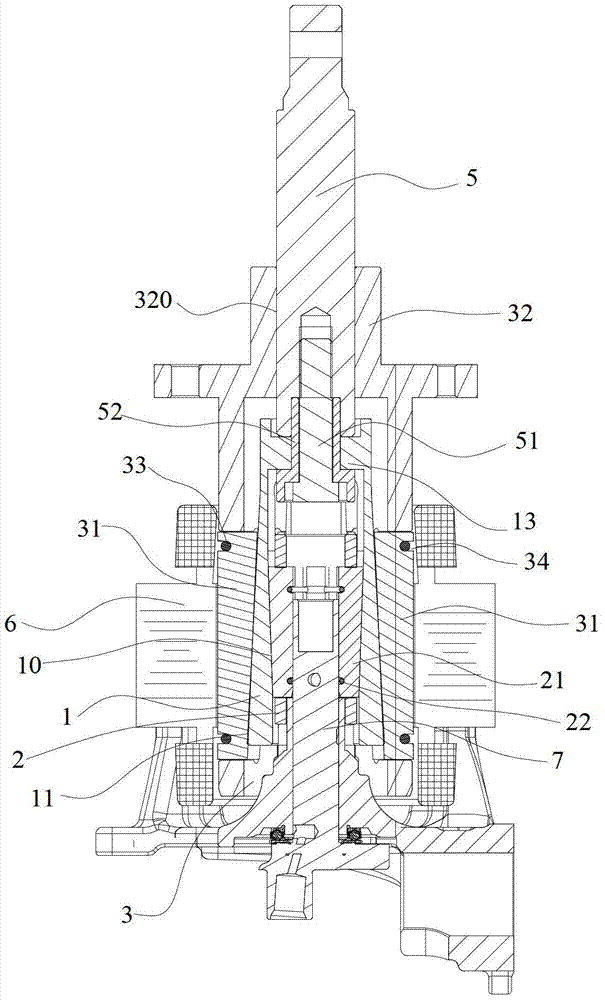

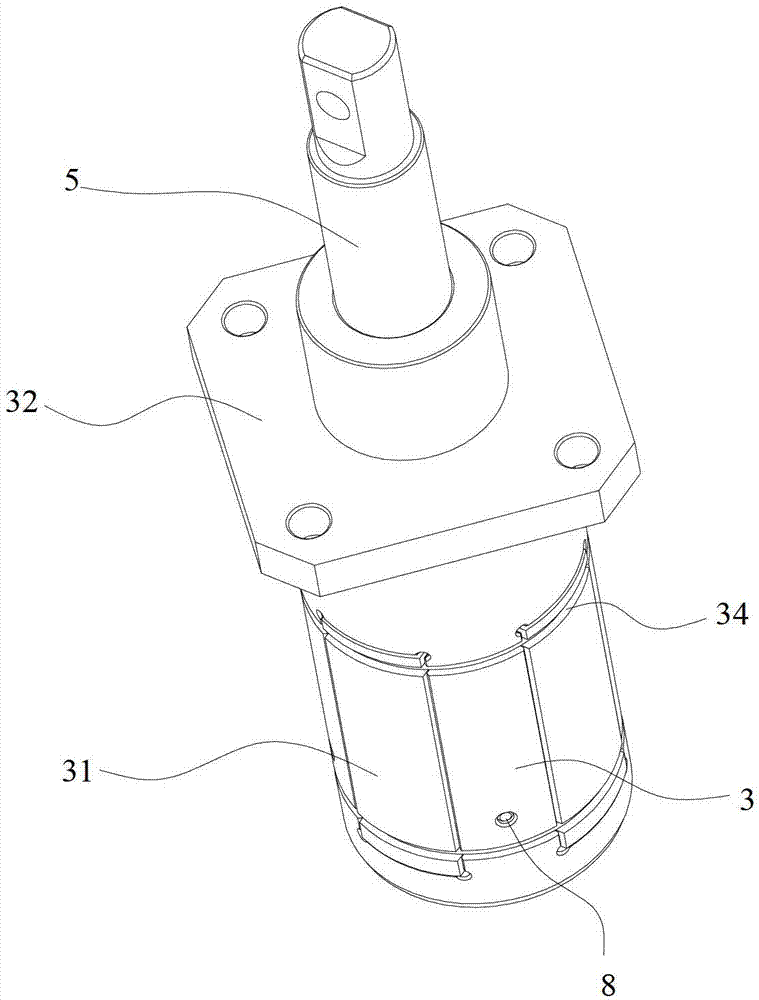

[0020] refer to Figure 1 ~ Figure 4 , the present invention provides an expansion shaft device for the installation of refrigeration compressor motors, including a tubular expansion shaft 1 and an inner expansion sleeve 2 and an outer expansion sleeve 3 coaxially arranged inside and outside the expansion shaft 1, the expansion shaft The inner surface of 1 is an inner cone surface 10 that gradually shrinks from top to bottom in the axial direction, and the outer surface of the expansion shaft 1 is an outer cone surface 11 that gradually expands from top to bottom in the axial direction. The inner expansion sleeve 2 and the outer expansion sleeve The side walls of the 3 are provided with a number of through holes 4 uniformly distributed along the circumferential direction, and the internal expansion sleeve 2 is provided with an inner slider 21 whose outer end fits with the inner tapered surface 10 in each through hole 4, and the outer expansion sleeve 3 Each through hole 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com