Exhaust gas turbocharger with cooled turbine housing

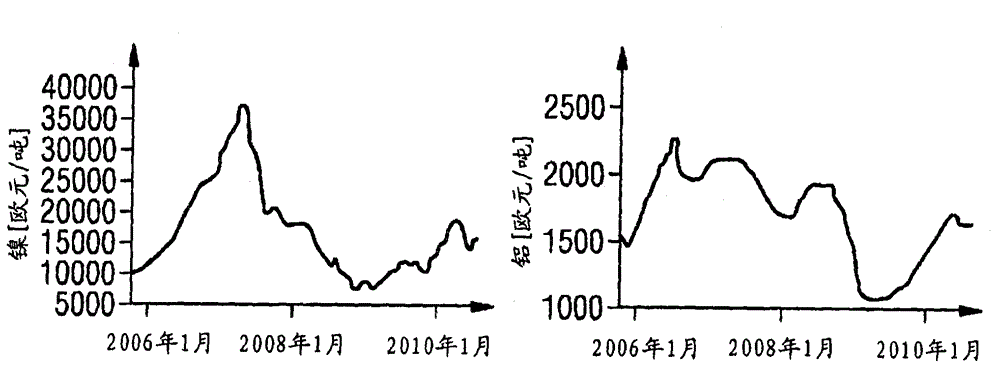

A technology for turbine casings and exhaust gas turbines, applied in the direction of machines/engines, gas turbine devices, components of pumping devices for elastic fluids, etc., can solve the problem of huge cost factors of nickel alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

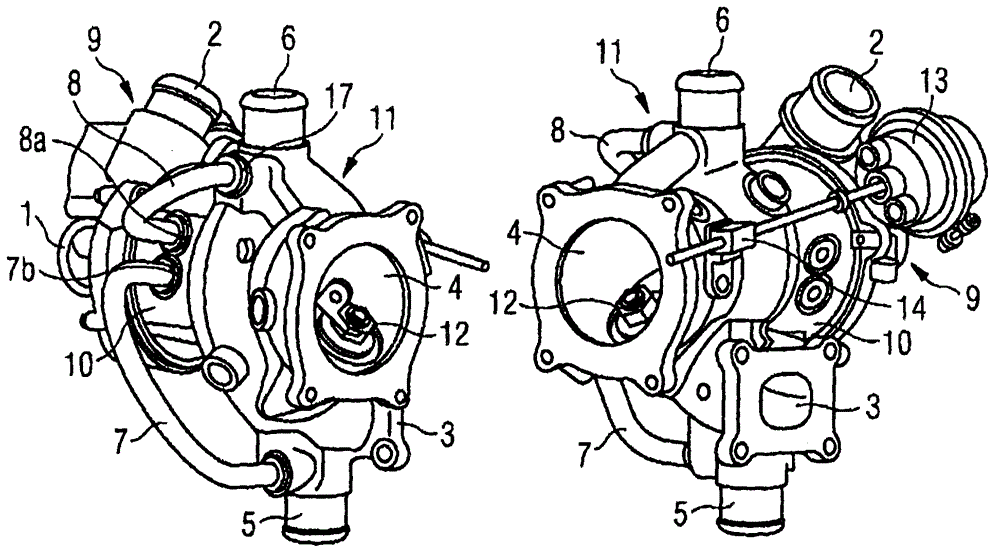

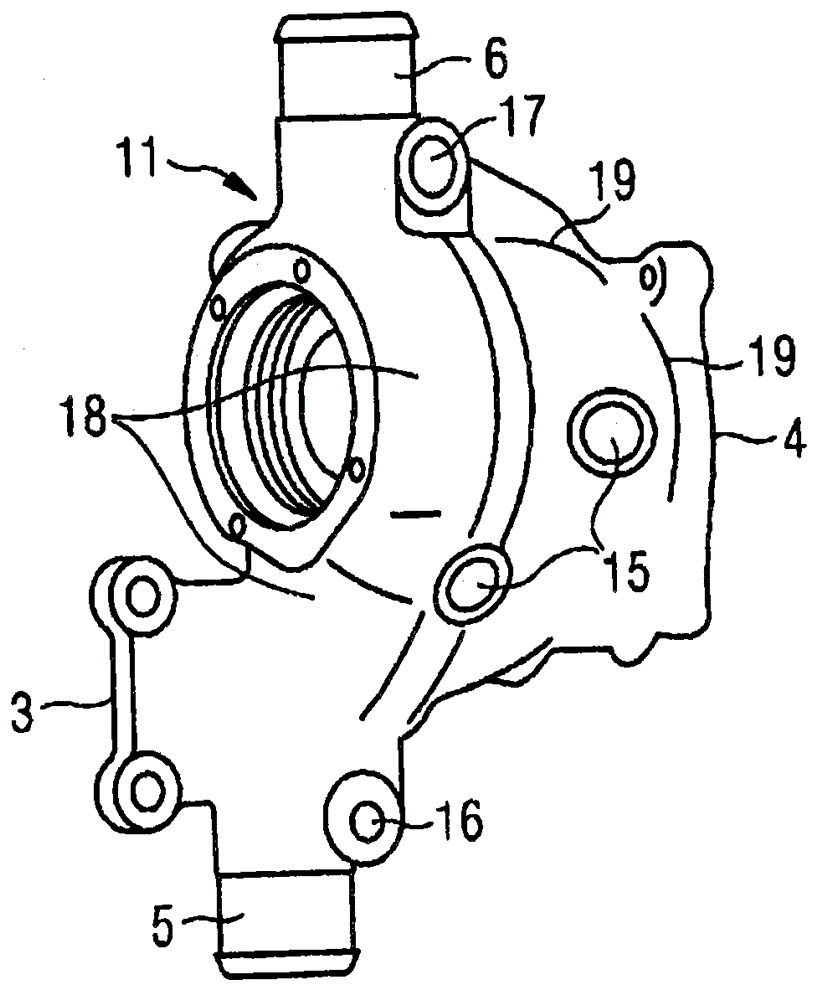

[0018] An exhaust gas turbocharger with a turbine housing, a bearing housing and a compressor housing is described below, wherein the turbine housing has a coolant inlet, a cooling water jacket arranged inside the turbine housing and a cooling agent outlet, and the cooling jacket is divided into two sub-areas.

[0019] from figure 2 It can be seen that the exhaust gas turbocharger shown there has a compressor housing 9 , a bearing housing 10 and a turbine housing 11 .

[0020] Compressor wheels arranged on a common shaft are arranged in the compressor housing 9 in a conventional manner. The turbines are arranged conventionally on a common shaft in the turbine housing 11 . The common shaft is mounted in a bearing housing 10 which is positioned between the compressor housing 9 and the turbine housing 11 . During operation of the exhaust gas turbocharger, the turbine is driven by the exhaust gas mass flow of the connected internal combustion engine and itself drives the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com