Cooling cover of welding equipment

A welding equipment and connection position technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of ineffective heat dissipation of the welding machine, and achieve convenient hoisting, uniform cooling, and balanced intake and exhaust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

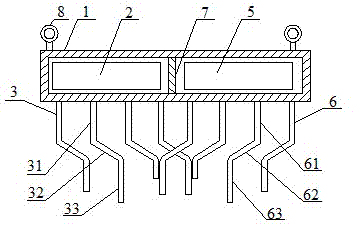

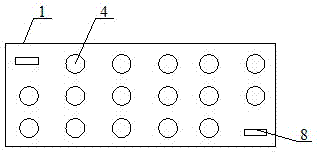

[0031] Such as figure 1 with figure 2 The cooling cover of the welding equipment shown includes a cover body 1, a first fan 2 and a plurality of exhaust pipes 3, the first fan 2 is arranged in the cover body 1, and the exhaust pipe 3 is arranged at the bottom of the cover body 1 and connected to the inside of the cover body 1 The space is connected, the connection position between the air extraction pipe 3 and the cover body 1 is located within the range of the first fan 2, the top of the cover body 1 is provided with an air hole 4, and the lengths of the plurality of air extraction pipes 3 are different.

[0032] When in use, this embodiment is arranged on the top of the welding machine. The exhaust pipe 3 extends into the inside of the welding machine, and the high-temperature air inside the welding machine is extracted by the first fan 2 to achieve the purpose of cooling the welding machine. The exhaust pipes 3 with different lengths can extend into positions of differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com