Plate-type capillary column, capillary column unit, and chromatography using same

一种毛细管柱、平板型的技术,应用在仪器、科学仪器、化学仪器和方法等方向,能够解决无法适用测定方法、难以实现、提高生产成本等问题,达到赋予扩展性、提高分辨率、减少制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

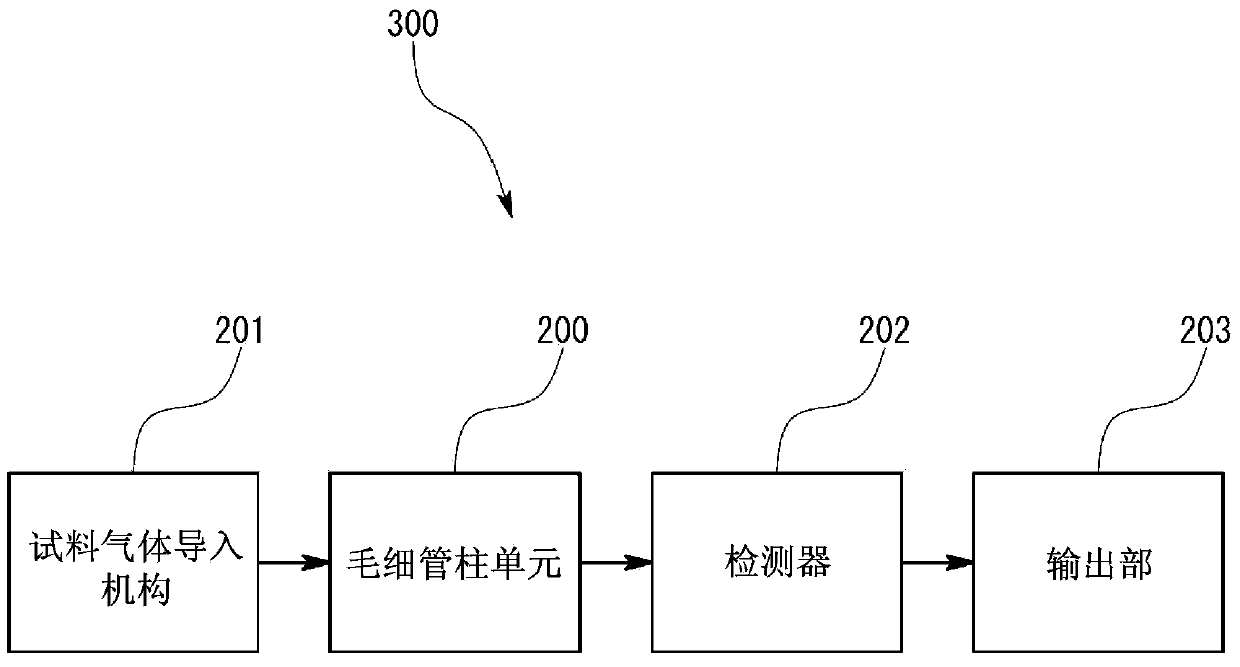

[0081] The capillary column unit 200 is configured by stacking a plurality of flat-shaped capillary columns 100 of the same shape in the thickness direction and communicating the capillaries 6 formed inside the flat-shaped capillary tubes 100 with each other.

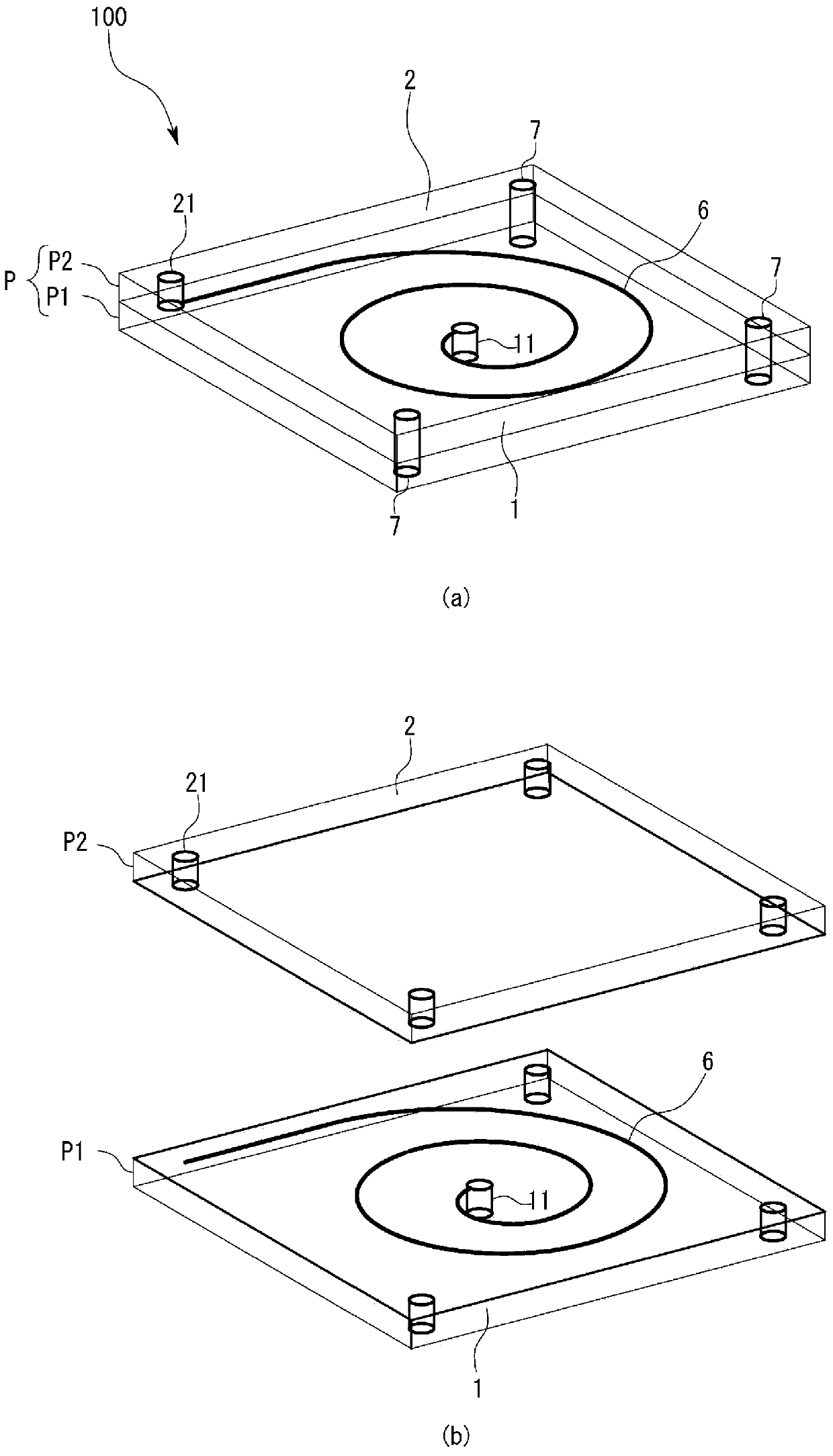

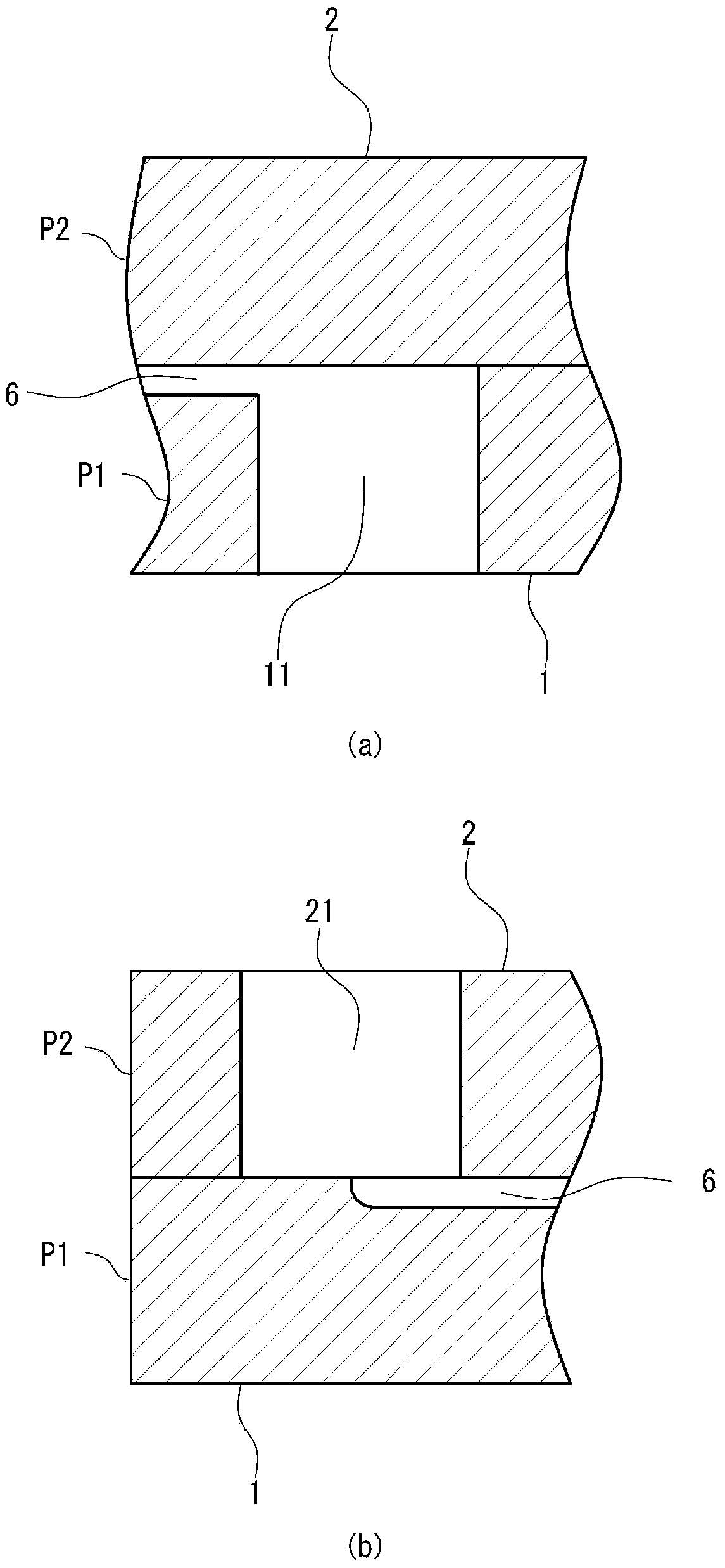

[0082] Such as figure 2 As shown in (a), the panel part of the flat capillary 100 is formed in a square shape, which is formed in a thin plate shape as a whole, and includes a flat plate P having a first panel part 1 and a second panel part 2 facing each other, forming Capillary 6 inside the flat plate P, blind holes 11, 21 and through holes 7 opened in the respective panel portions 1, 2 of the flat plate P in a direction perpendicular to the respective panel portions 1, 2. That is, the capillary 6 is a flow path formed in the plate P, and has no external opening except for the connected blind holes 11 and 21 . Therefore, the capillary 6 is formed so that it does not come into contact with the outside air except for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com