Switch with arcing chamber

A switch and arc technology, applied in the field of switches with arc extinguishing chamber, to achieve reliable and fast arc extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

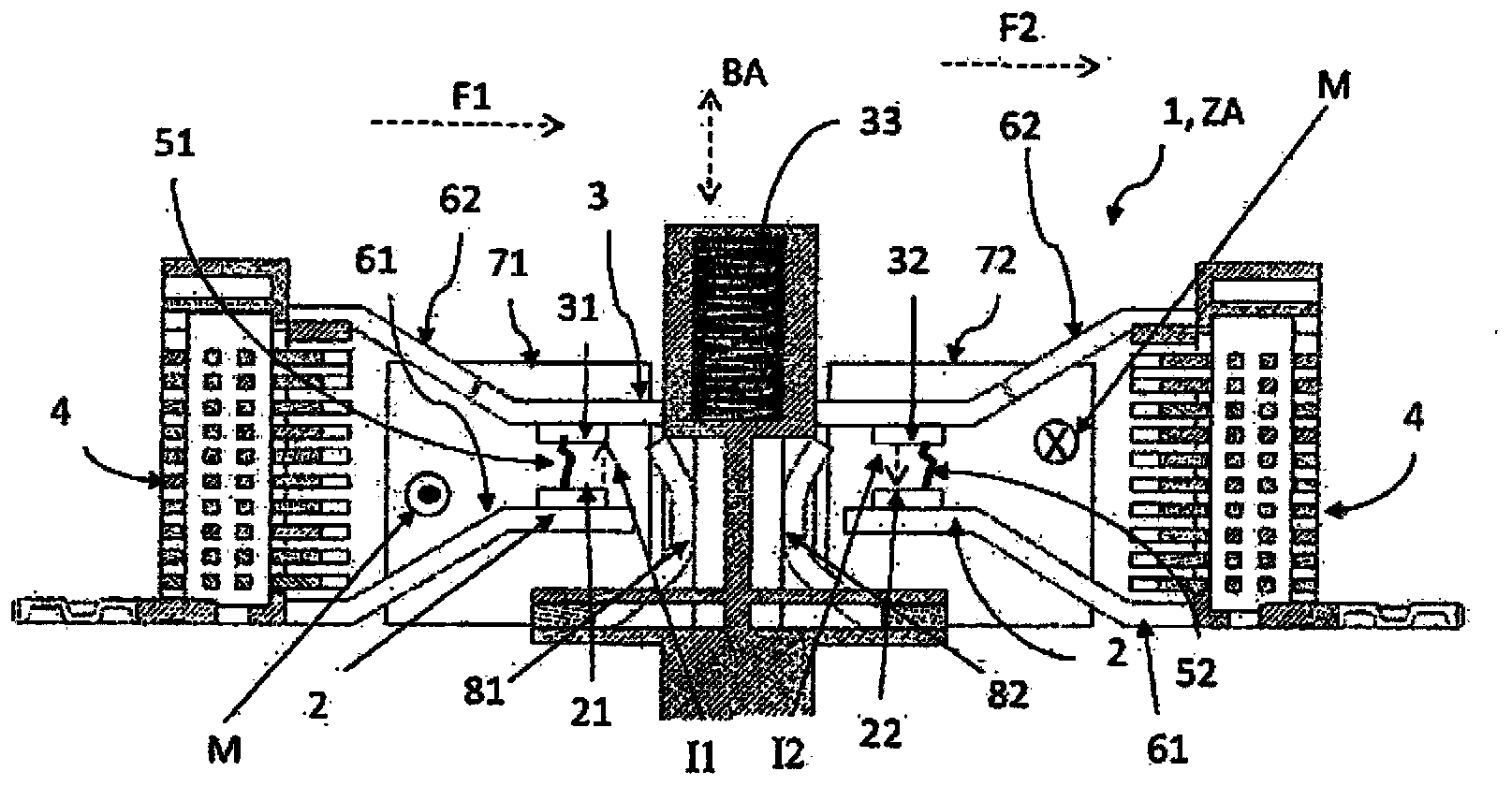

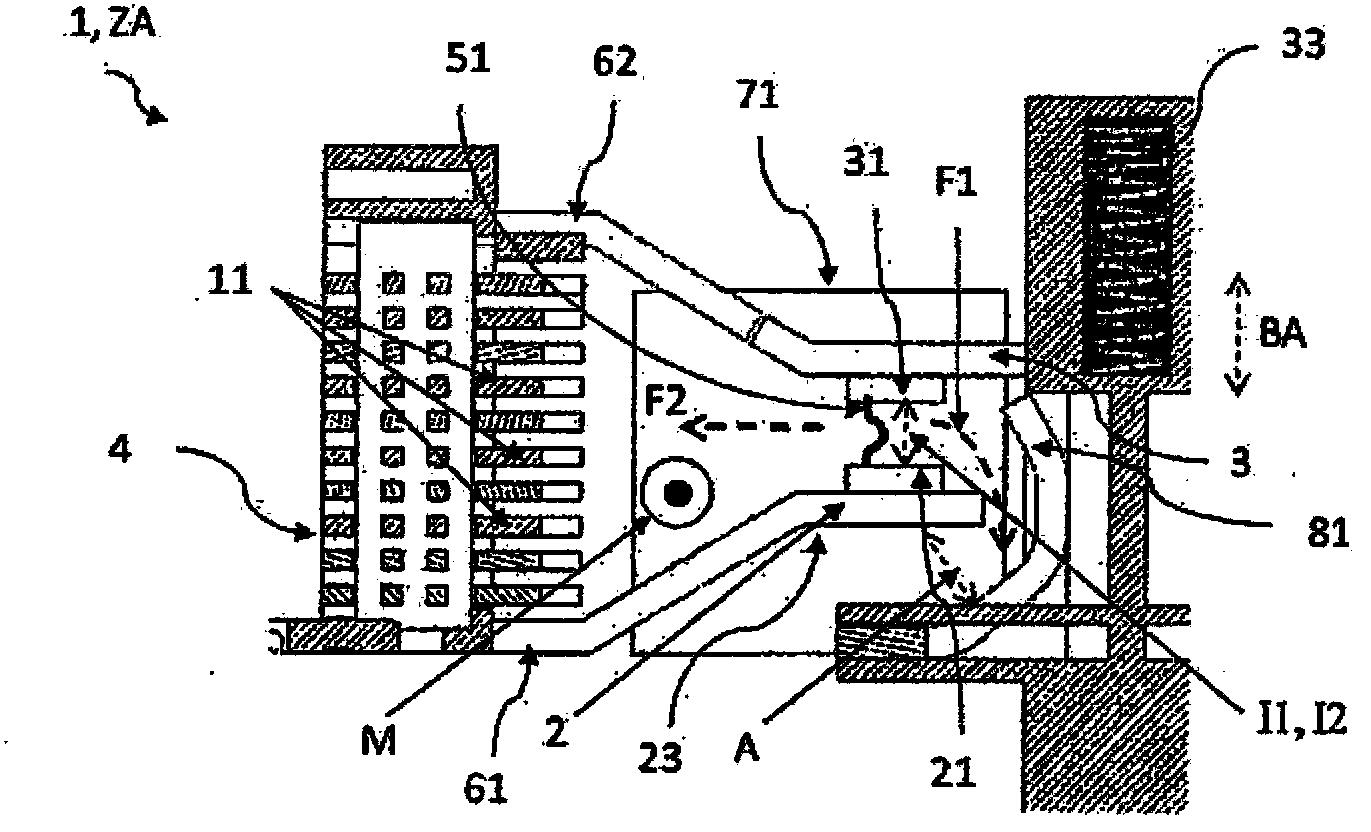

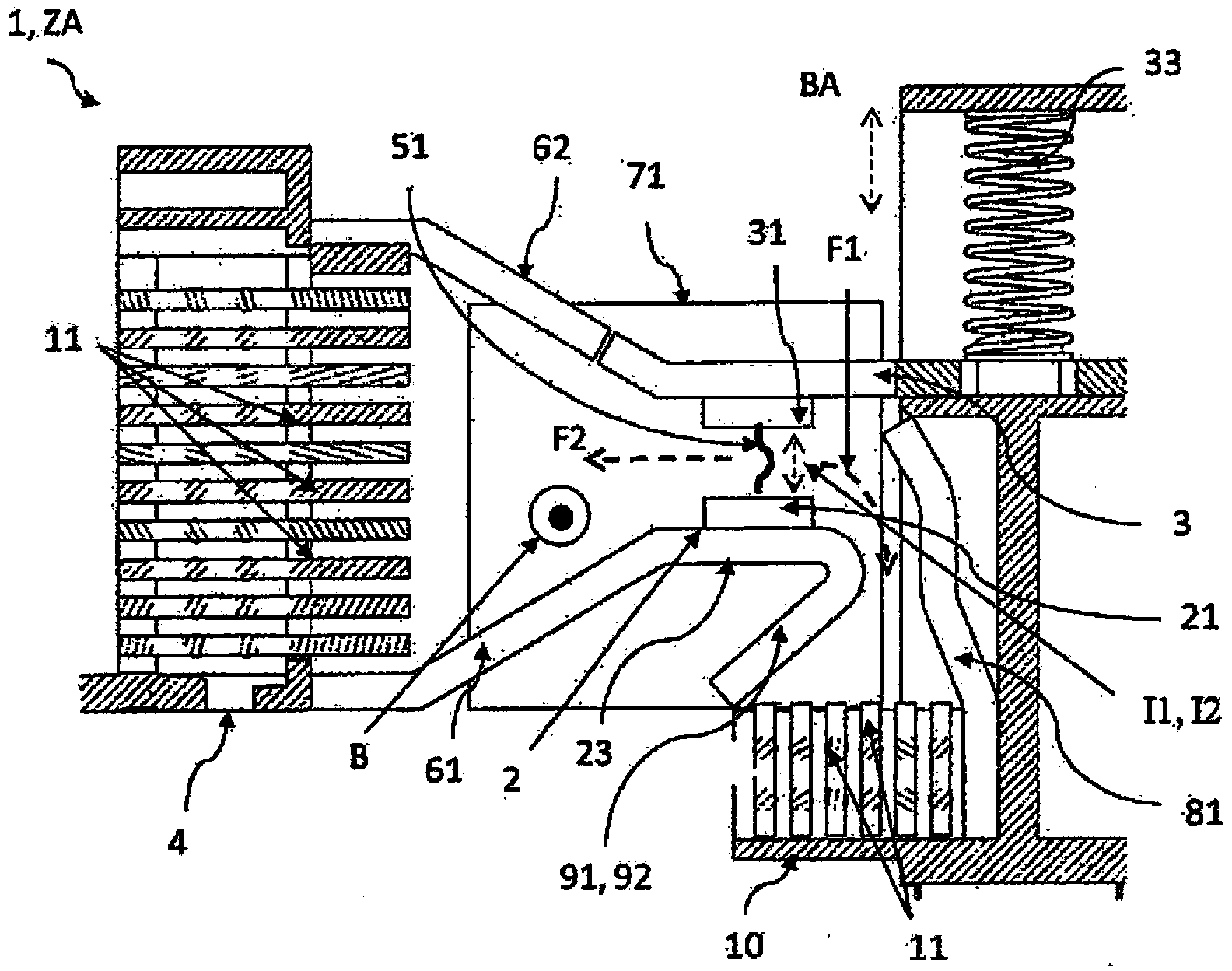

[0025] figure 1 with figure 2 A cross-section of an embodiment of a switch chamber of a switch 1 according to the invention is shown. For the sake of clarity, the drawing is limited to the switch chamber of the switch. It is well known to those skilled in the art that besides the switch chamber, the switch must have other components. Switch 1 is polarity independent due to its construction for DC operation. The entire switch is shown in a symmetrical embodiment in figure 1 in, while figure 2 For better understanding, show figure 1 A magnified view of the left portion of the switch. To this end, the switch 1 comprises: two separate fixed contacts 2 each having a first contact area 21; and a movable conductive bridge contact 3 having second contact areas 31, 32 which The points contact each other along the axis of movement BA of the bridge contact to create an electrically conductive connection between the first contact area 21 , 22 and the second contact area 31 , 32 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com