Engine cylinder head end face drilling and milling method

A technology of engine cylinder head and processing method, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of engine cylinder head structure complexity, influence of cylinder head processing efficiency, large flatness of positioning surface, etc. Achieve the effects of reducing excessive flatness, precise clamping, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

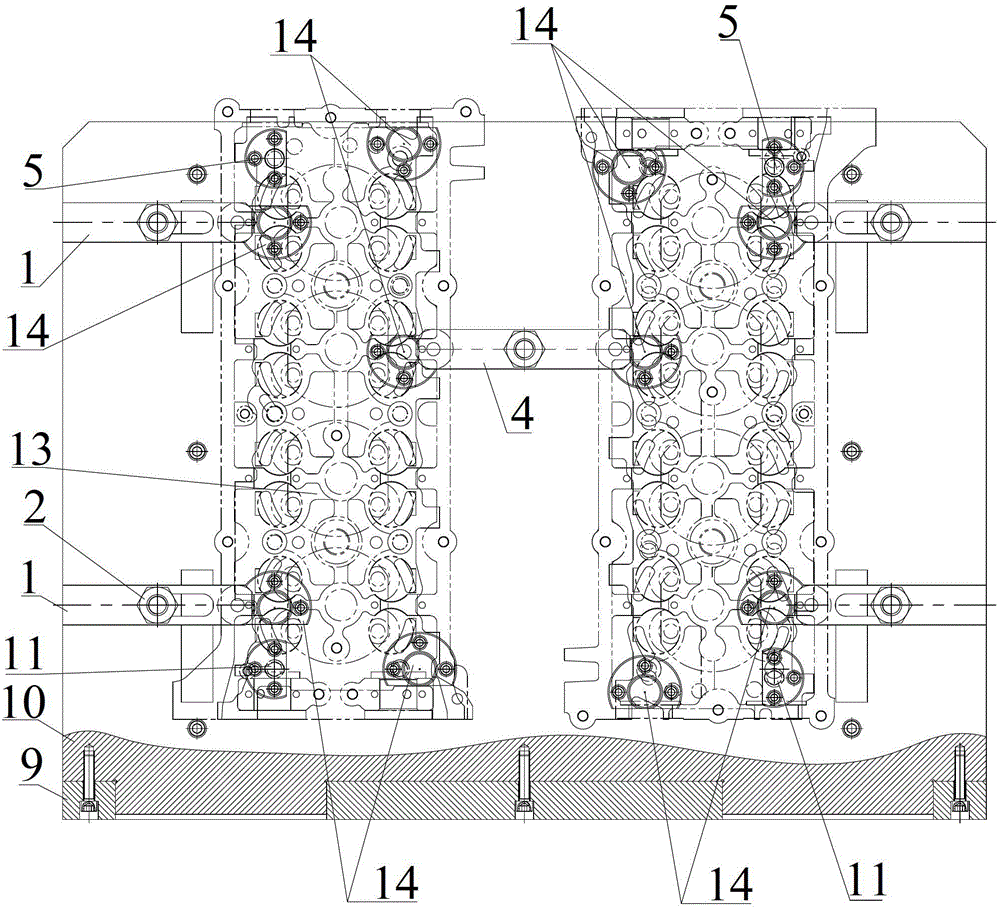

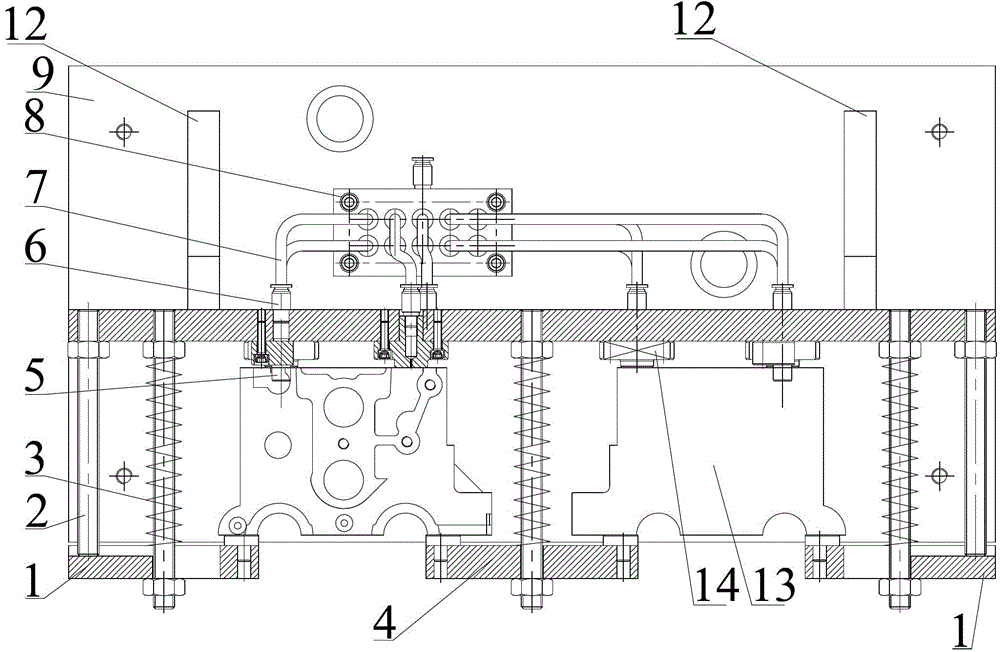

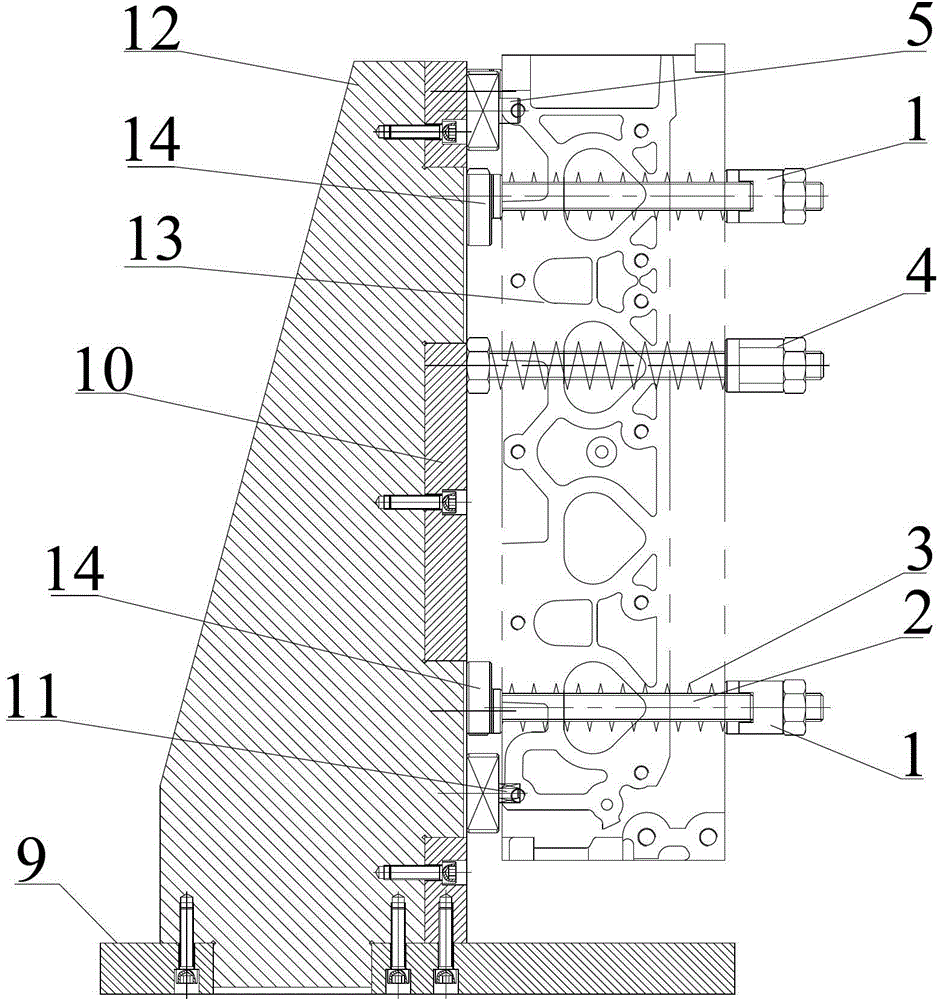

[0022] The invention relates to a drilling and milling processing method for an end face of an engine cylinder cover, which comprises a clamping process for clamping the cylinder cover, a subsequent drilling and milling process, and the like. The main inventive point of the present invention lies in the improvement of the clamping process, and other processes are similar to the traditional processing method. In the clamping process of this drilling and milling processing method, a special fixture is used. The fixture is as follows: figure 1 , figure 2 with image 3 As shown, the fixture includes a base and a panel 10 for placing the cylinder head 13 on the base. The panel 10 is provided with a pressing mechanism for pressing the cylinder head 13 and a positioning mechanism for positioning the cylinder head 13. The positioning mechanism includes Several top surfaces are planar supporting nails 14, and the cylinder head 13 is placed on the supporting plane formed jointly by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com