Compound micro-nano three-dimensional printing system

A three-dimensional printing, micro-nano technology, applied in the innovative technology field of composite micro-nano three-dimensional printing system, can solve the problems that have not been commercialized, and achieve the effect of effective utilization, ingenious design and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

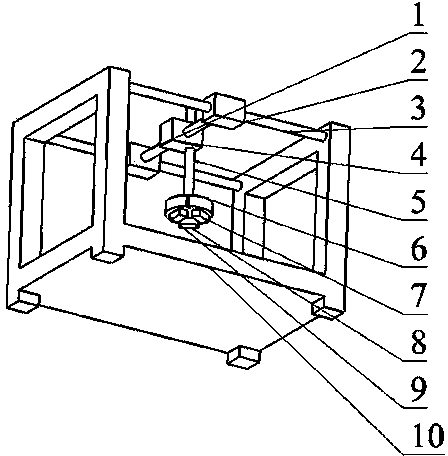

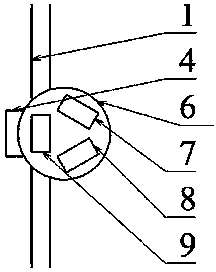

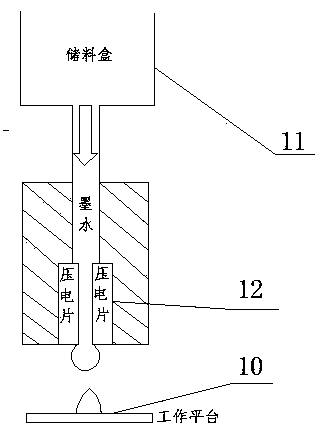

[0020] The structure diagram of the present invention is as figure 1 , 2 , 3, and 4, including a working platform 10, an X-axis guide rail 1 for adjusting the relative position of the working nozzle and the working plane in the X direction, and a Y-axis guide rail 3 for adjusting the relative position of the working nozzle and the working plane in the Y direction , the Z-axis guide rail 5 that realizes the adjustment of the relative position of the working nozzle and the working plane in the Z direction, the first guide rail bearing platform 2 and the second guide rail bearing platform 4 that are used to carry the nozzle and slide on the guide rail correspondingly, and are used for rotation adjustment The disc fixture 6 at the position of the working nozzle, the disc fixture 6 is equipped with a piezoelectric printing nozzle 7 for traditional two-dimensional printing, a piezoelectric three-dimensional printing nozzle 8 for low-precision three-dimensional printing, and a piezoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com