Automatic leveling control device

A control device and leveling technology, applied in the directions of transportation, packaging, elevators, etc., can solve the problems of insufficient precision, inaccurate leveling, time-consuming and labor-intensive, etc., and achieve the effect of eliminating accumulated errors and improving precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

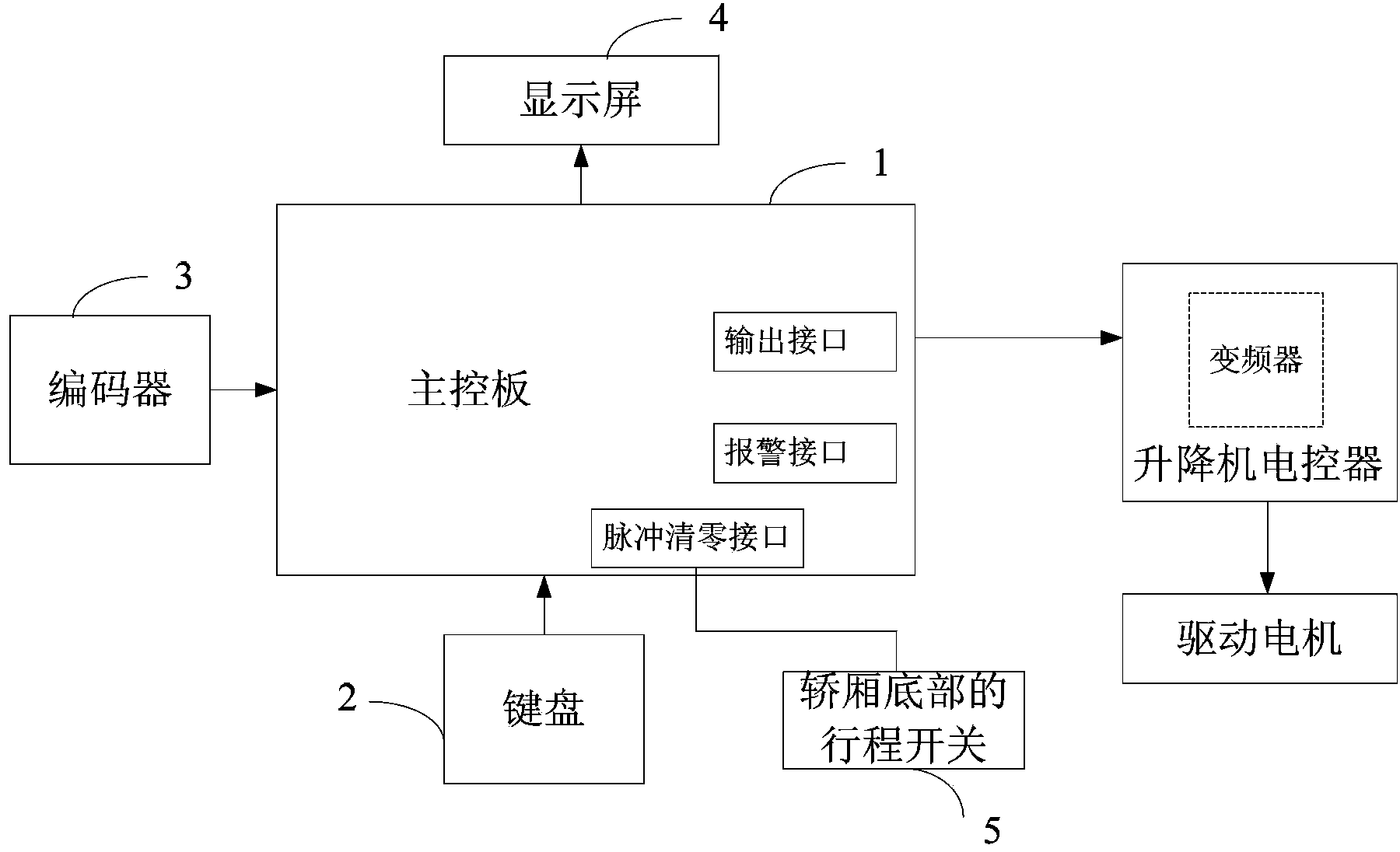

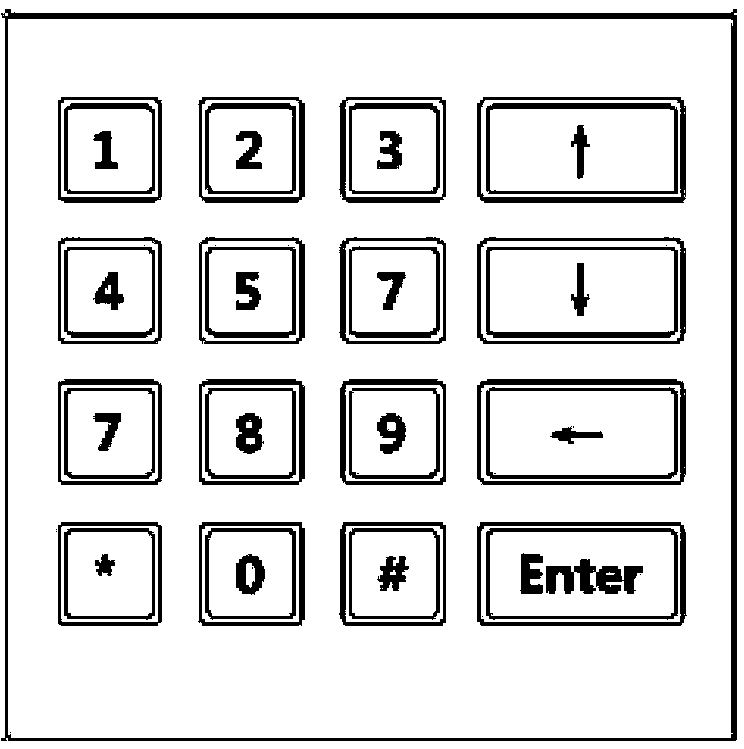

[0019] Such as figure 1 Shown: an automatic leveling control device, including a main control board 1, a keyboard 2, an encoder 3 installed on the gear shaft of the elevator, and a display screen 4 installed in the elevator car; the main control board 1 is connected to the The display screen 4, keyboard 2 and encoder 3; the main control board 1 is also connected to the electric controller of the elevator through the output interface on the main control board 1.

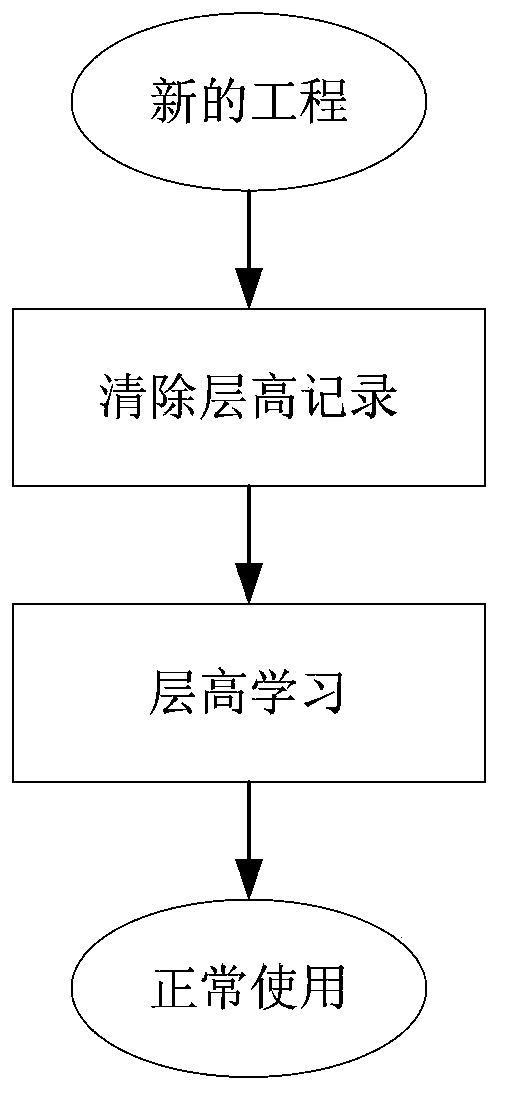

[0020] The working principle of the present invention is as follows: the improvement of the present invention lies in the added encoder 3, the encoder 3 is installed on the gear shaft of the elevator, and as the gear shaft rotates, the encoder 3 turns according to the number of turns of the gear shaft and angle, output the number of pulses corresponding to the lift car's rising or falling height. For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com