Drum washing machine

A technology for drum washing machines and washing tubs, which is applied to other washing machines, washing devices, textiles and papermaking, etc. It can solve the problems of affecting the washing effect, poor washing effect, and small friction between clothes, and achieve the effect of optimizing the washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

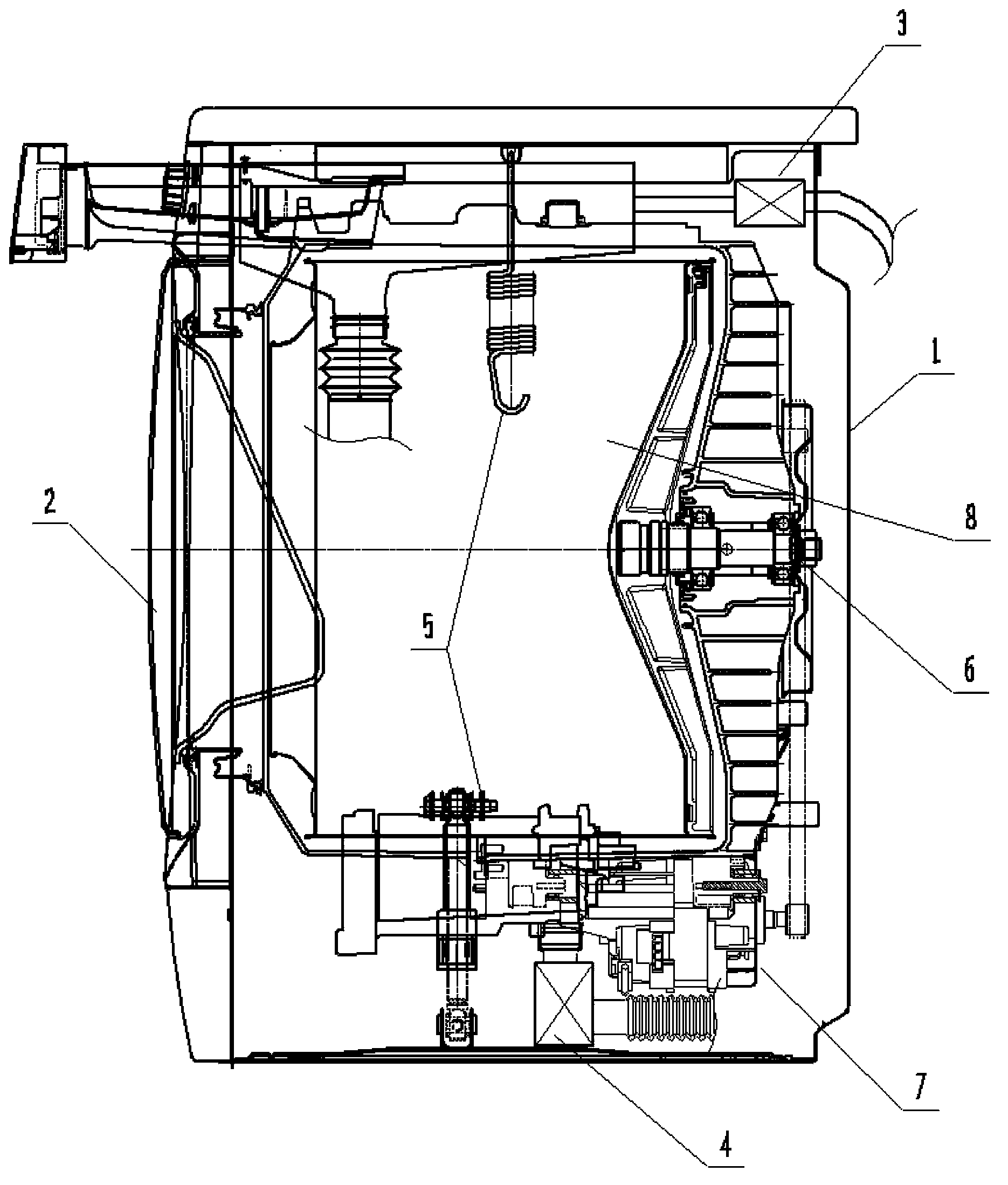

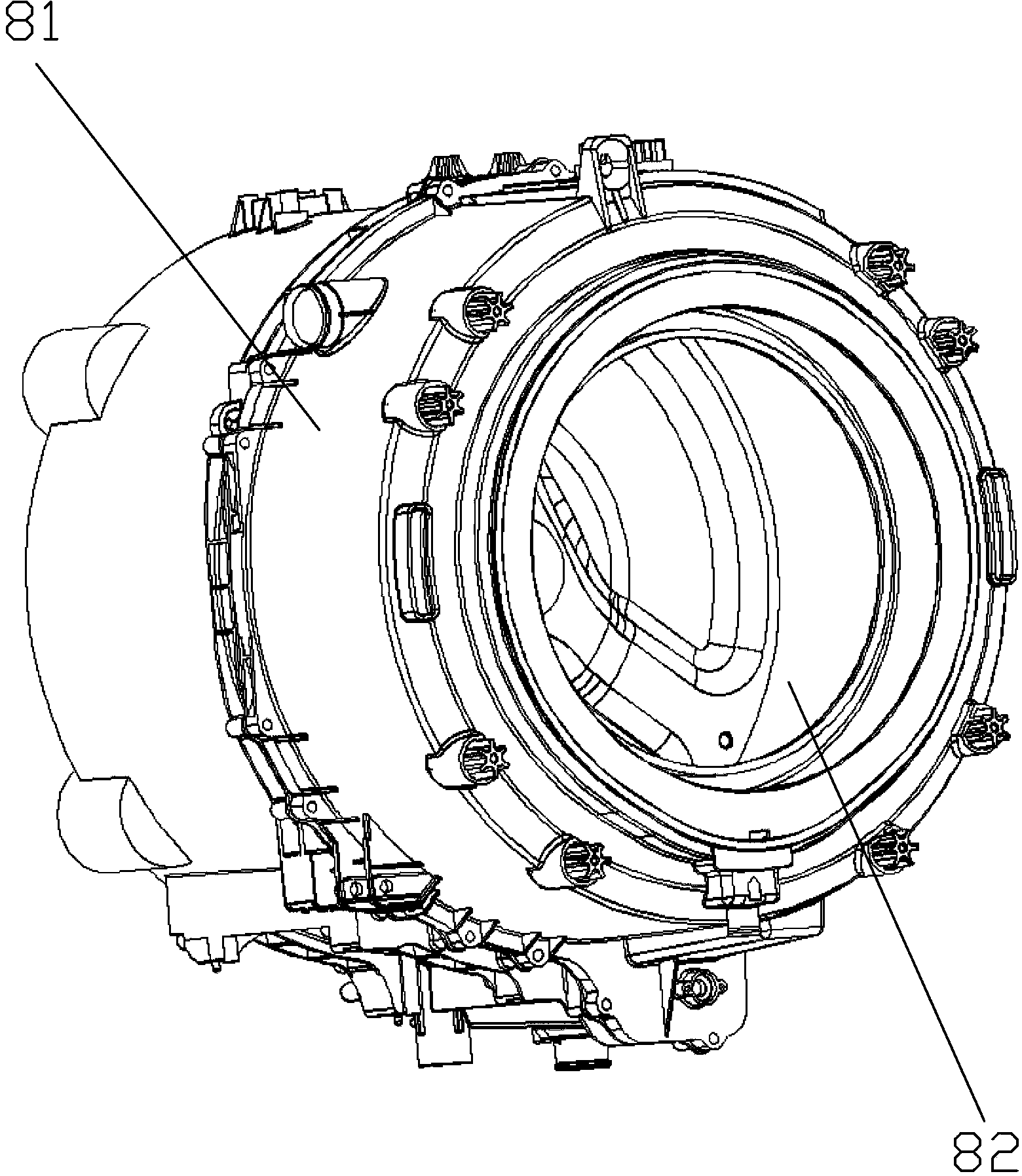

[0029] refer to Figure 2 to Figure 5 , is a drum washing machine of the present invention, comprising a box body, a water tub 81 and a washing tub 82, the water tub 81 is installed in the box body, the washing tub 82 is rotatably installed in the water tub 81, the Wash tub 82 is a resin molding. In the field, the water tub 81 is also called an outer tub, and the washing tub 82 is also called an inner tub, and the water tub 81 and the washing tub 82 together constitute a washing tub.

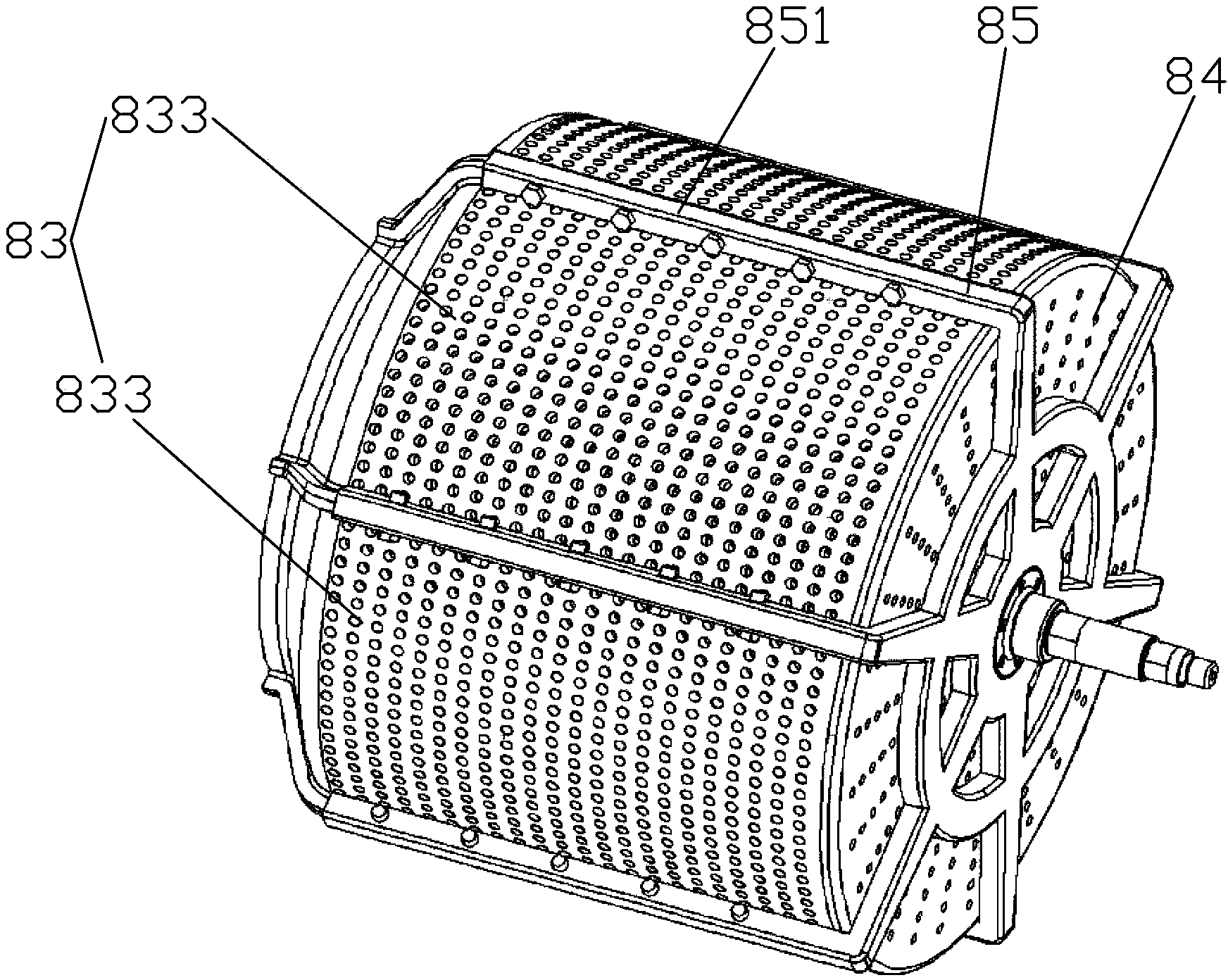

[0030] The washing bucket 82 includes a resin bucket body 83 and a resin back cover 84. The resin back cover 84 is mounted on one end of the resin bucket body 83. In this embodiment, the resin bucket body 83 is in an assembled form, and the resin bucket body 83 is formed by assembling circumferentially of several arc-shaped resin plates 833 .

[0031] Flanges 834 are provided at the joints of the arc-shaped resin plates 833 , and adjacent arc-shaped resin plates 833 are fixed together through ...

Embodiment 2

[0037] Please refer to Figure 7 The difference of this embodiment is that: the inner wall of the washing bucket 82 is provided with a friction bump 10, and the shape of the friction bump 10 can be semicircular, elliptical, wavy, etc., which is used for clothing friction and improves cleaning. degree. The friction bumps 10 are evenly distributed on the resin barrel body 83 . The axial lifting ribs 9 in the first embodiment and the friction bumps 10 in this embodiment can also be provided on the resin barrel 83 at the same time.

Embodiment 3

[0039] Please refer to Figure 8 , The difference of this embodiment is that: the inner wall of the washing tub 82 is provided with several guiding ribs 11, and the length direction of the guiding ribs 11 forms an angle with the axial direction of the washing tub. This angle is 30° to 60°. The guide rib 11 is conducive to the movement of the water flow, so that the water flow moves along the axial direction of the washing bucket,

[0040] The guide ribs 11 are parallel to each other, and the ends of the adjacent guide ribs 11 are not aligned with each other. Compared with the case where the ends are aligned, the unaligned arrangement can make the water flow have greater kinetic energy, which is beneficial to washing clothes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com