Hollow oil pumping device for fluid producing profile tests

A liquid-producing profile and hollow technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of logging cable winding, size limitation of running instruments, and low oil well production, so as to ensure firmness , prevent the effect of reverse sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

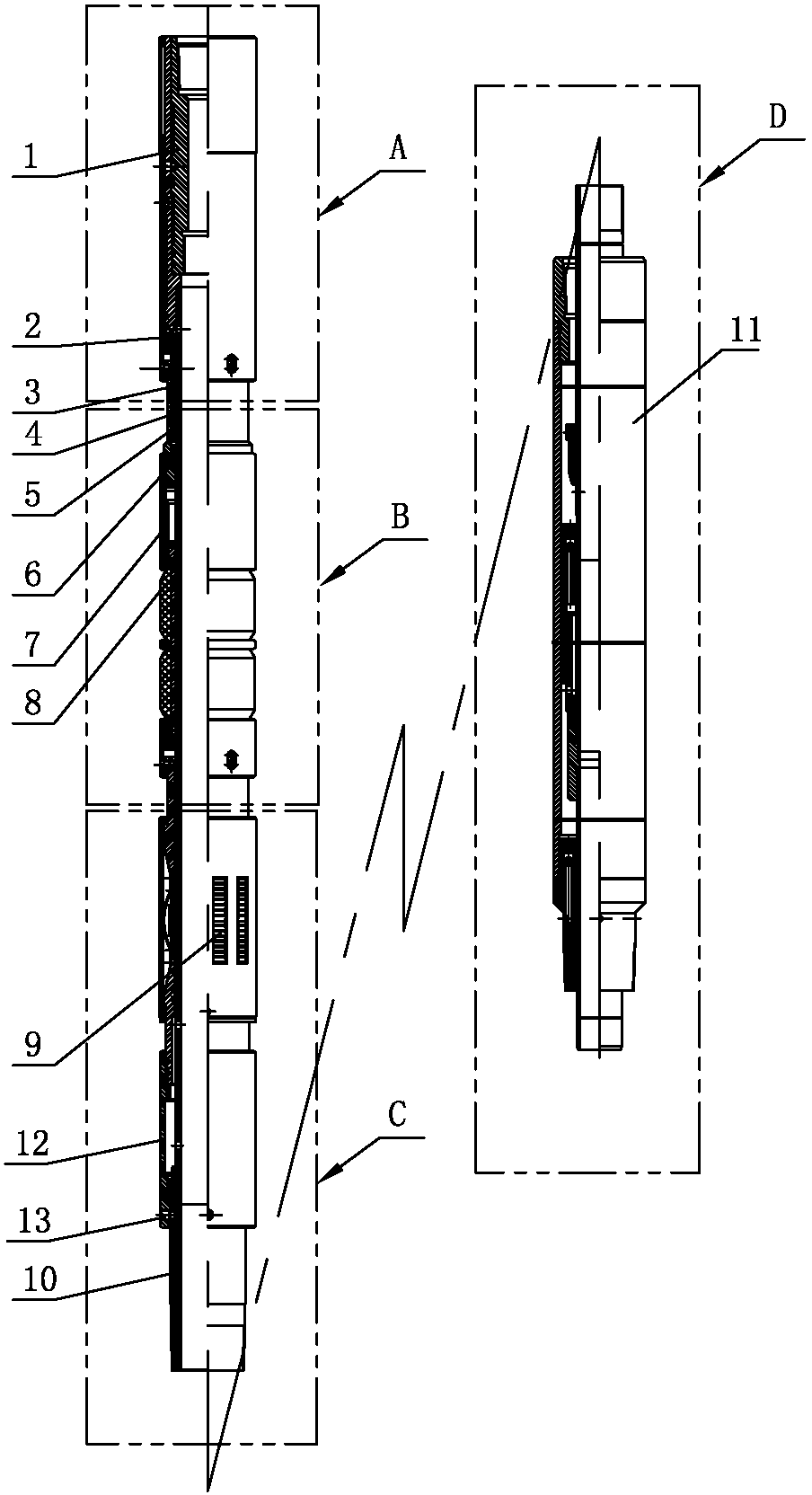

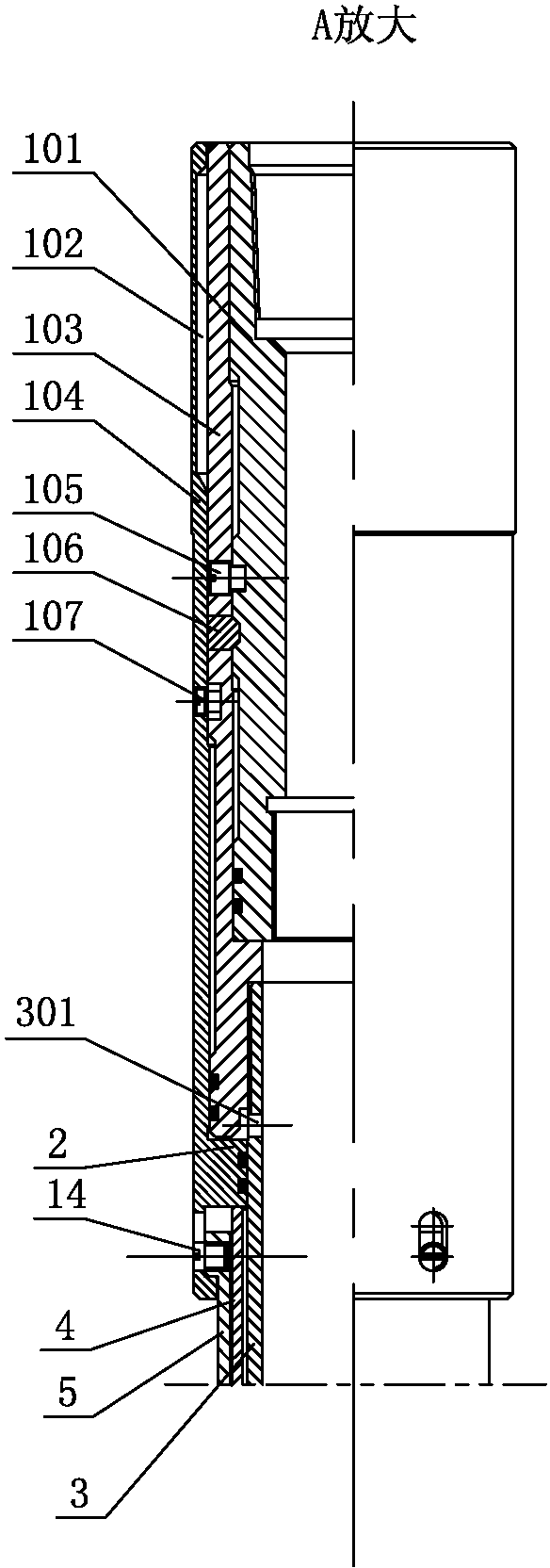

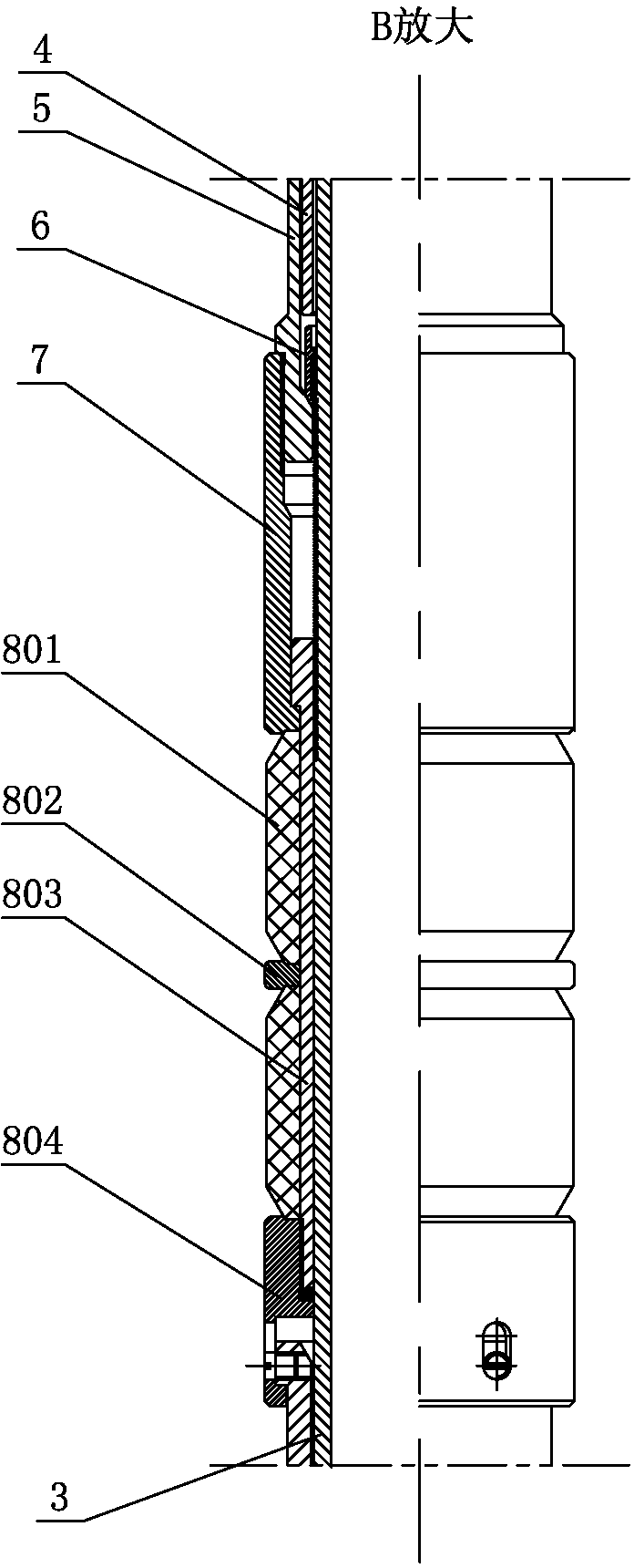

[0019] Such as figure 1 — Figure 6 Shown is the hollow oil pumping device for liquid production profile test of the present invention, which includes a central pipe 3, the upper end of the central pipe 3 is threaded to the hand joint 1, the lower end of the central pipe 3 is threaded to the lower joint 10, and the lower end of the lower joint 10 is connected to a hollow rod Oil well pump 11, the outer wall of the center pipe 3 on the lower side of the hand-off joint 1 is slid sequentially covered with an upper inner ferrule 4 and a lock ring 6, the upper inner ferrule 4 and the lock ring 6 are covered with a lock ring sleeve 5, and the inner wall of the lock ring 6 is in contact with the The outer wall of the center tube 3 on the lower side of the lock ring 6 is respectively provided with one-way locking teeth that engage with each other, the outer wall of the lower end of the lock ring sleeve 5 is threadedly connected to the thrust sleeve 7, and the outer periphery of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com