Compression type shock absorption sleeve

A shock-absorbing sleeve and compression technology, which is applied in the direction of springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve problems such as damage to elastic bodies, and achieve high life, good buffering effect, and good carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

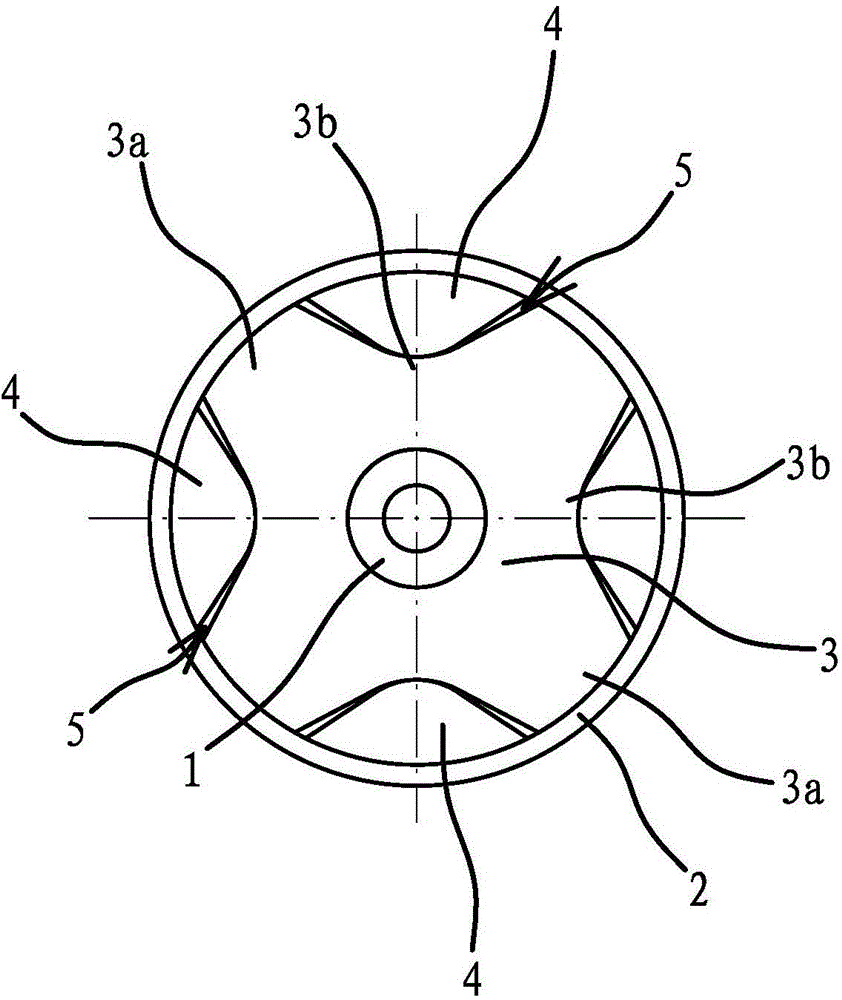

[0025] Such as figure 1 As shown, the compression shock absorbing sleeve includes a rigid inner cylinder 1 and a rigid outer cylinder 2 sleeved outside the inner cylinder 1, and an elastic body 3 made of rubber is adhered between the inner cylinder 1 and the outer cylinder 2 The outer side of the elastic body 3 includes a connecting portion 3a that is vulcanized and adhered to the inner wall of the outer cylinder 2 and a depressed pressure receiving portion 3b. The elastic body 3 is made of rubber and is vulcanized and adhered to the inner cylinder 1. It has high elasticity and high corrosion resistance. Strong, and at the same time make the inner cylinder 1 and the outer cylinder 2 have a better connection effect. As ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com