An anti-shaking device for preventing the wall of a flame boiler from shaking

A boiler furnace wall and flame technology, which is applied in the combustion method, combustion chamber, cover/lining, etc., can solve the problems of anti-slosh failure, fatigue damage of furnace wall, and being pulled off, and achieve effective anti-slosh and reduce the amplitude of sloshing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

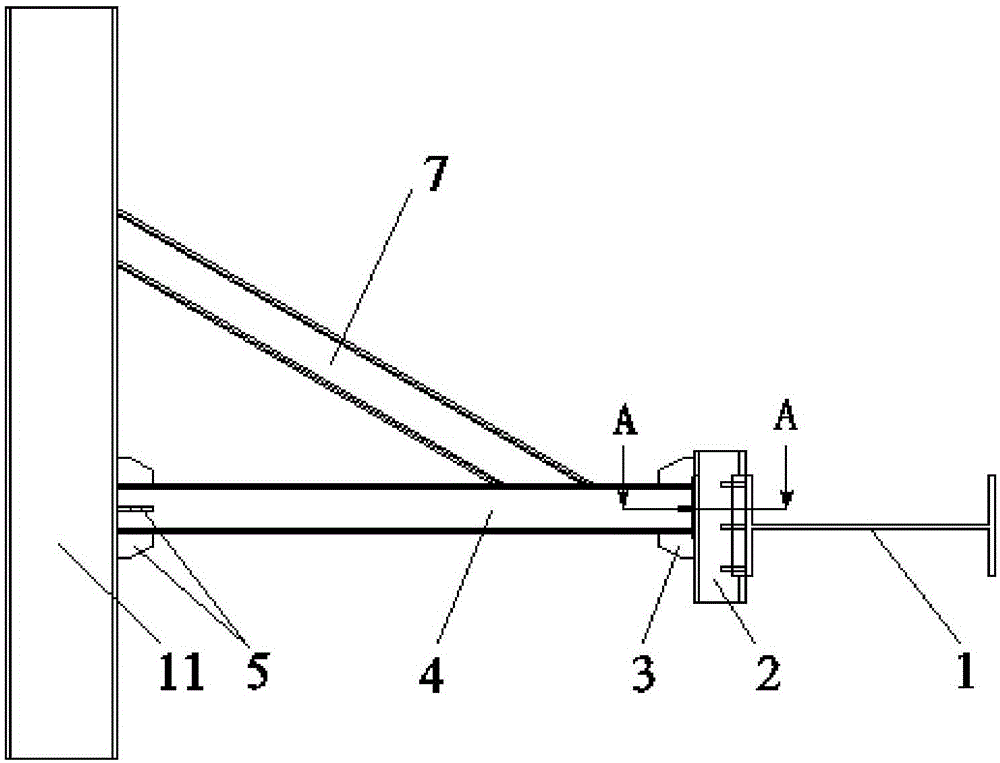

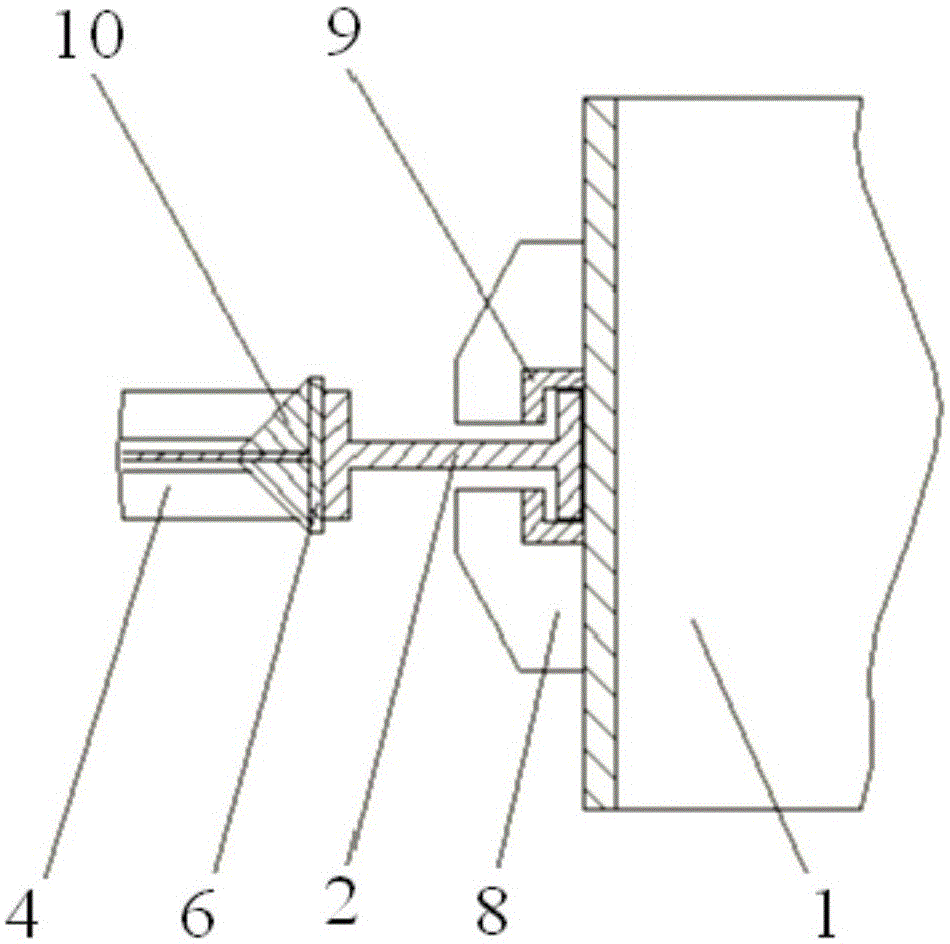

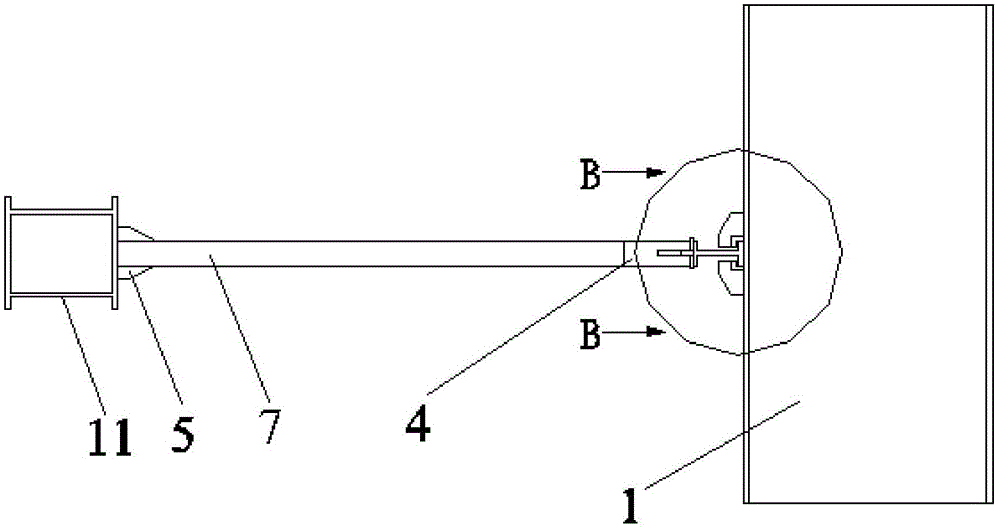

[0018] see Figure 1-5 , the present invention is an anti-sway device 14 for preventing the furnace wall of a flame boiler from shaking, which is connected between the horizontal rigid beam 1 on the water wall of the boiler furnace wall 12 and the vertical column 11 of the supporting steel frame of the boiler . The boiler furnace wall 12 is originally designed with multi-layer horizontal rigid beams 1 , which are spaced apart from each other by a certain height, and are used to reinforce and restrain the furnace wall 12 . The horizontal rigid beam 1 is the place where the anti-sway device 14 takes root on the furnace wall, and the vertical column 11 is the place where the anti-sway device 14 takes root on the steel frame of the boiler (the vertical column 11 belongs to the important part of the steel frame supporting the boiler. According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com