Diesel engine four-cylinder crankshaft capable of preventing shaking

A diesel engine and crankshaft technology, which is applied to the crankshaft, engine components, engine lubrication, etc., can solve the problems of reducing the transmission accuracy of the four-cylinder crankshaft, affecting the service life of the four-cylinder crankshaft, and increasing the vibration of the four-cylinder crankshaft, so as to reduce cylinder movement Stuck, improved kinetic energy transmission efficiency, and reduced transmission wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

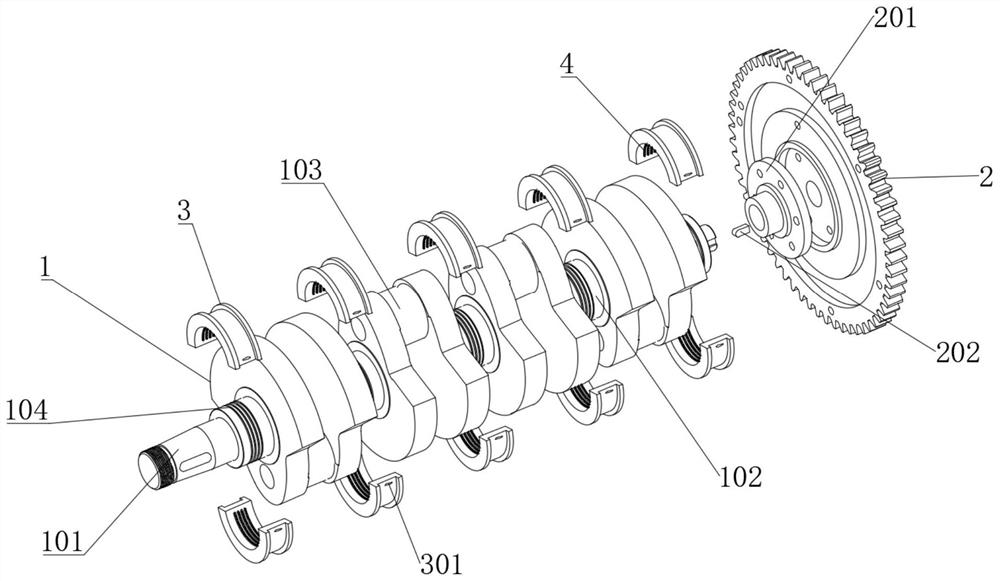

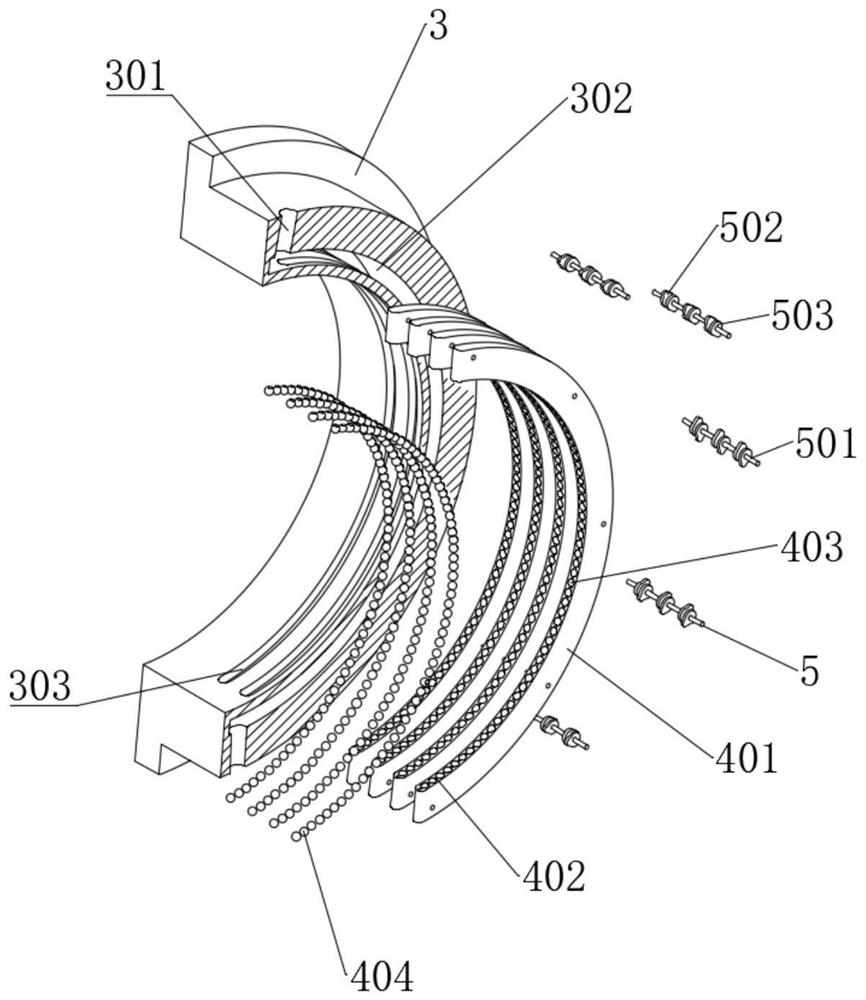

[0052] see Figure 1-10 , a four-cylinder diesel engine crankshaft for preventing shaking, comprising a crankshaft body 1, the crankshaft body 1 includes a main shaft 102, a plurality of eccentrically arranged connecting rod shafts 103 are fixedly connected to the main shaft 102, and the outer ends of the main shaft 102 are fitted with multiple Two main force shaft half sets 3 arranged in pairs, and a plurality of main force shaft half sets 3 arranged in pairs are respectively arranged at intervals with the connecting rod shaft 103, and the inner wall of the main force shaft half sets 3 is equipped with a plurality of anti-shake lubrication components 4, anti-vibration The outer side of the shaking lubrication assembly 4 is connected with a plurality of damage induction assemblies 5 distributed in circular arcs. The anti-shaking lubrication assembly 4 includes an anti-shaking buffer arc bar 401, and the inner wall of the main shaft half sleeve 3 is provided with a plurality of ...

Embodiment 2

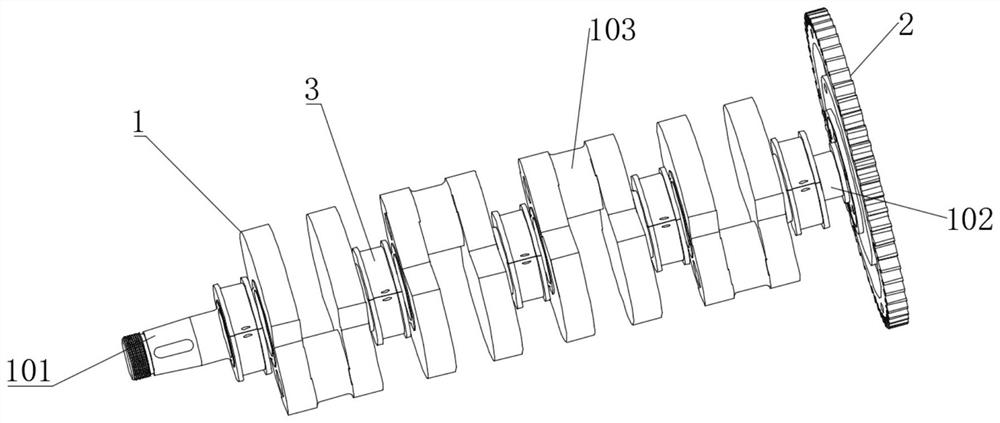

[0065] see Figure 1-11 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 11 , the installation method of crankshaft body 1 comprises the following steps:

[0066] S1. Pre-install the main shaft half sleeve 3 located on the lower side to the crankshaft installation place of the fuel engine casing;

[0067] S2. Then install the crankshaft body 1 into the fuel engine casing, and make the main shaft 102 correspond to the main shaft half sleeve 3 located on the lower side, so that the anti-shake buffer arc 401 snaps into the anti-shake groove 104 of the main shaft;

[0068] S3. Finally, install the upper main shaft half sleeve 3 on the main shaft 102 so that the anti-shake buffer arc 401 snaps into the corresponding main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com