Vertical air-cooled condenser

A condenser and vertical wind technology, applied in the field of wine making, can solve the problems of waste of water resources, uncontrollable wine temperature, and low cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

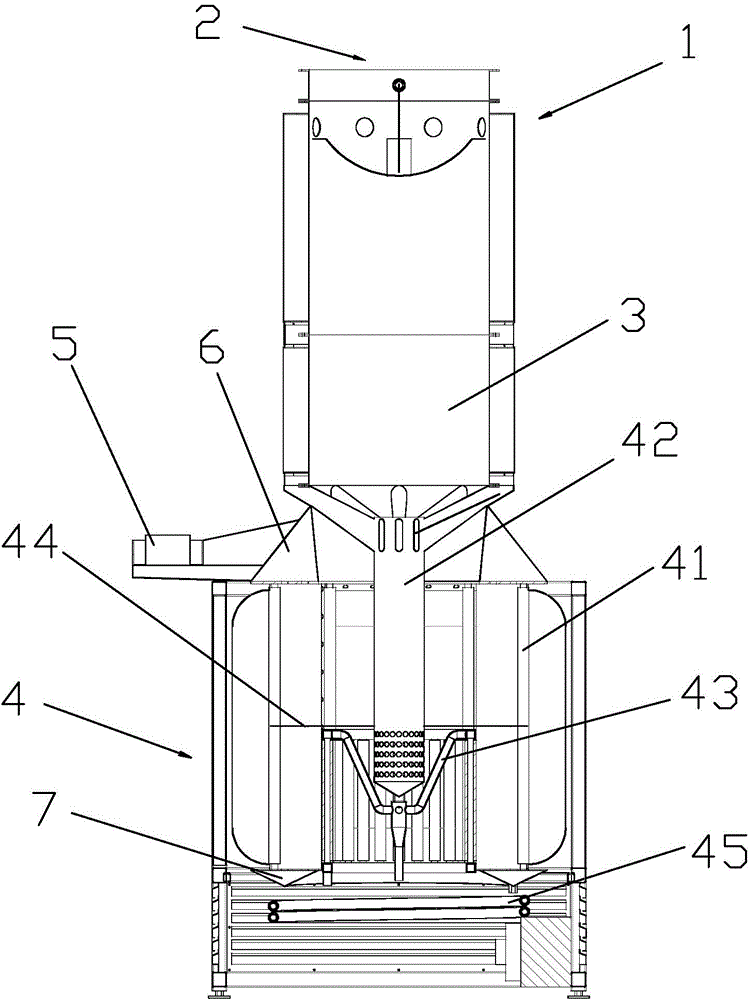

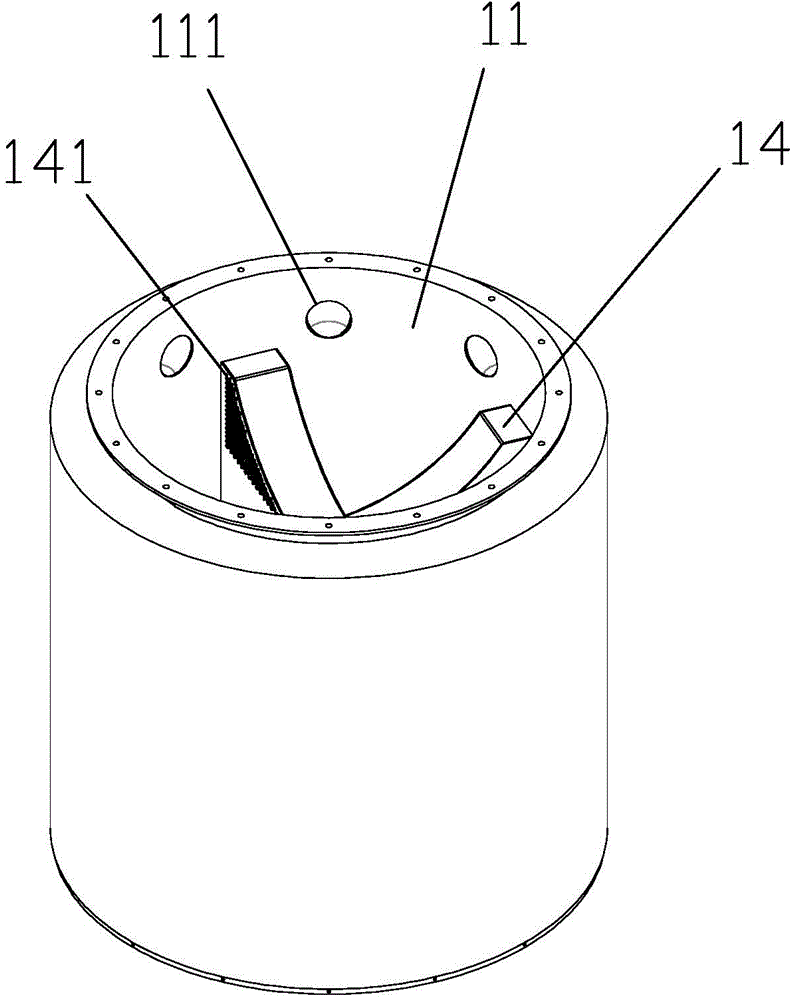

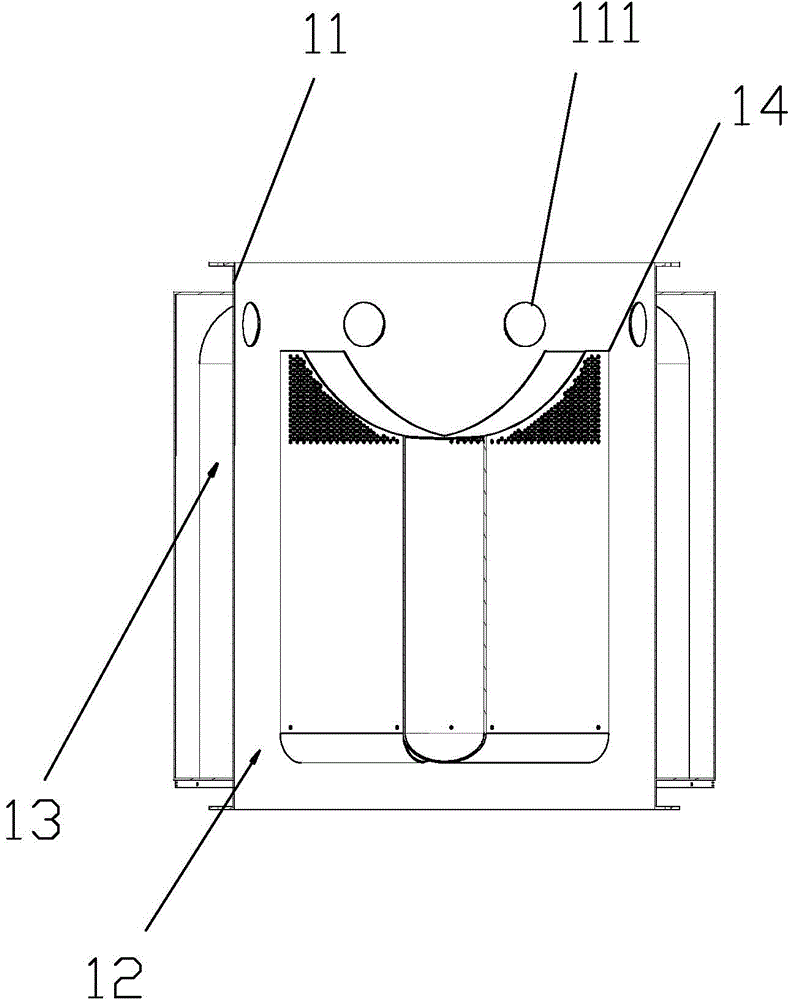

[0027] As shown in the figure, a vertical air-cooled condenser disclosed by the present invention includes a muffler 1, a fan 3, a cooling chamber 4, and a condensation system composed of a wine gas condensation pipe 41. The muffler 1 is arranged on the fan 3, The fan 3 is located above the cooling chamber 4, and when the fan 3 is activated, air can be blown out from the upper opening of the muffler 1, thereby forming an air flow inside the condenser.

[0028] Wherein cooling chamber 4 tops are provided with air inlet 5, and air inlet 5 is communicated with wine gas buffer chamber 6 on cooling chamber 4 top, and wine gas buffer chamber 6 is communicated with wine gas condensation pipe 41 in cooling chamber 4, and wine gas condenses The lower end of the pipe 41 is the effusion chamber 7, which will fall into the effusion chamber 7 after being co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com