A vehicle heat exchange system

A technology of heat exchange system and heat exchange box, which is applied in the direction of machines/engines, generators/motors, mechanical equipment, etc., can solve the problem of insufficient utilization of heat dissipated, and achieve simple structure, large effective output torque, and fuel utilization high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the features and advantages of the present invention more obvious and easy to understand, specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

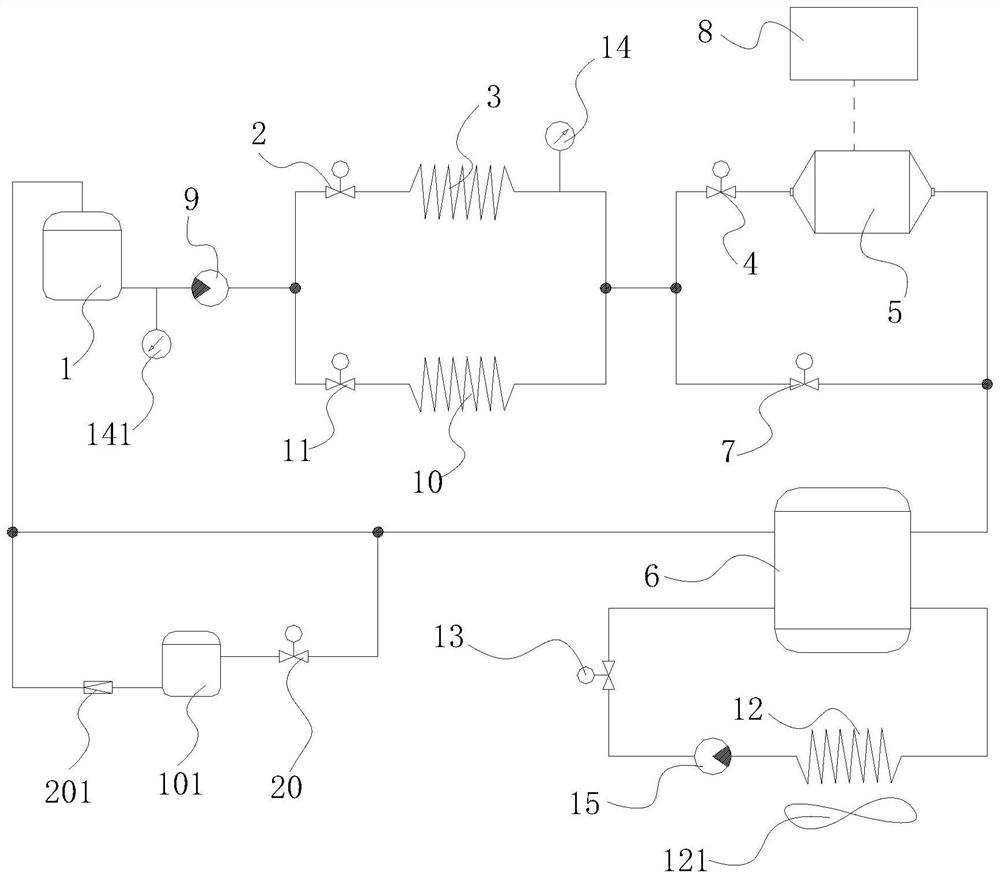

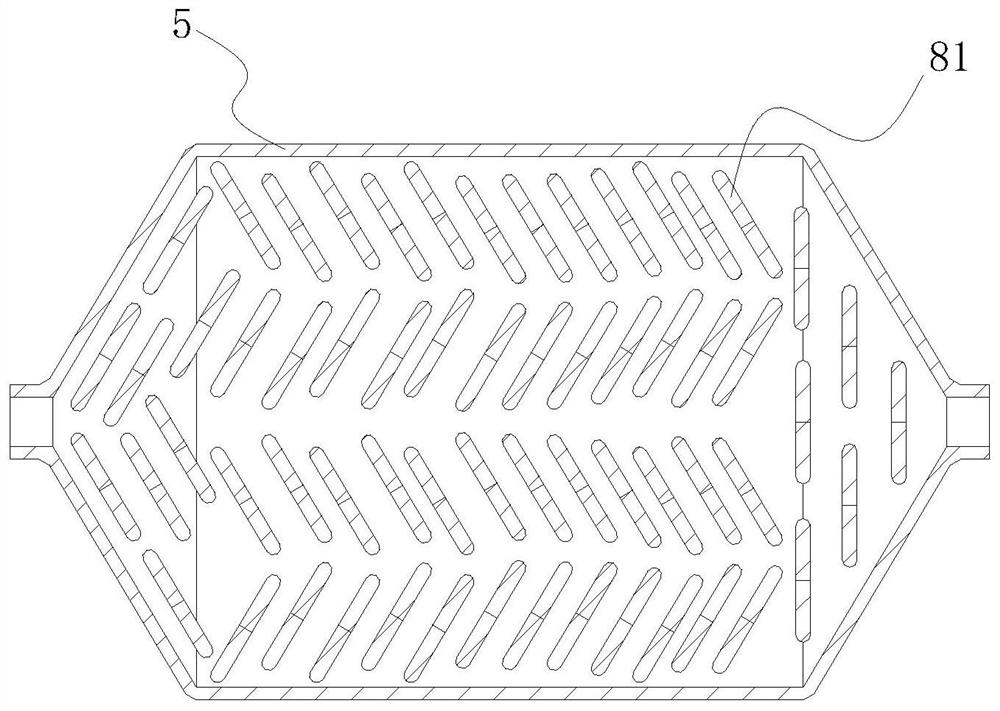

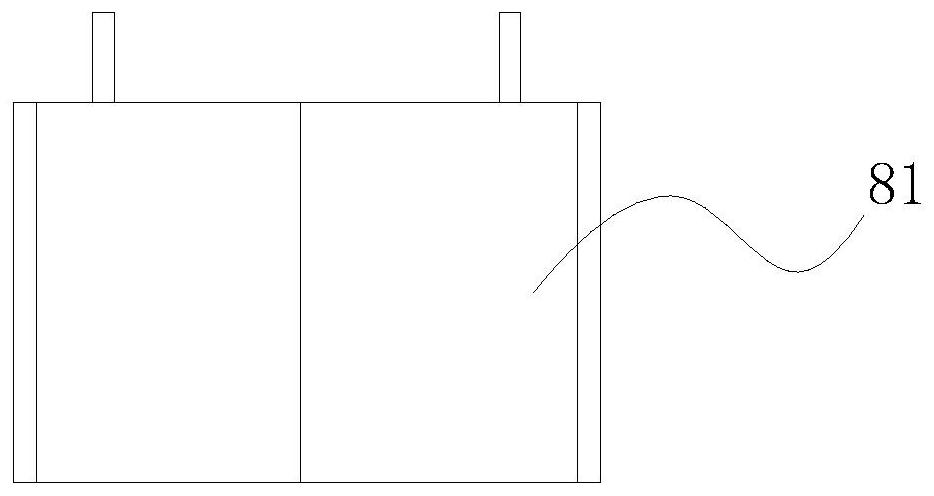

[0021] combine Figures 1 to 3 , a vehicle heat exchange system, comprising a coolant tank 1, a first electrically controlled proportional valve 2 connected to the outlet of the coolant tank 1, the coolant tank 1 is adapted with a circulating pump 9, the first electrically controlled proportional valve 2 The valve 2 is connected with the first cooling line 3 of the engine; the first cooling line 3 is connected with the heat exchange box 5 through the electronic thermometer 14 and the second electronically controlled proportional valve 4 in turn, and the heat exchange box 5 is connected with the heat exchange box 5. The heat accumulator 6 is connected, the outlet of the heat accumulator 6 is connected to the coolant tank 1, the inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com