An oxygen sensor durability test device

A technology of oxygen sensor and testing device, applied in the field of oxygen sensor, can solve problems such as troublesome implementation, distortion of real environment simulation, waste of manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

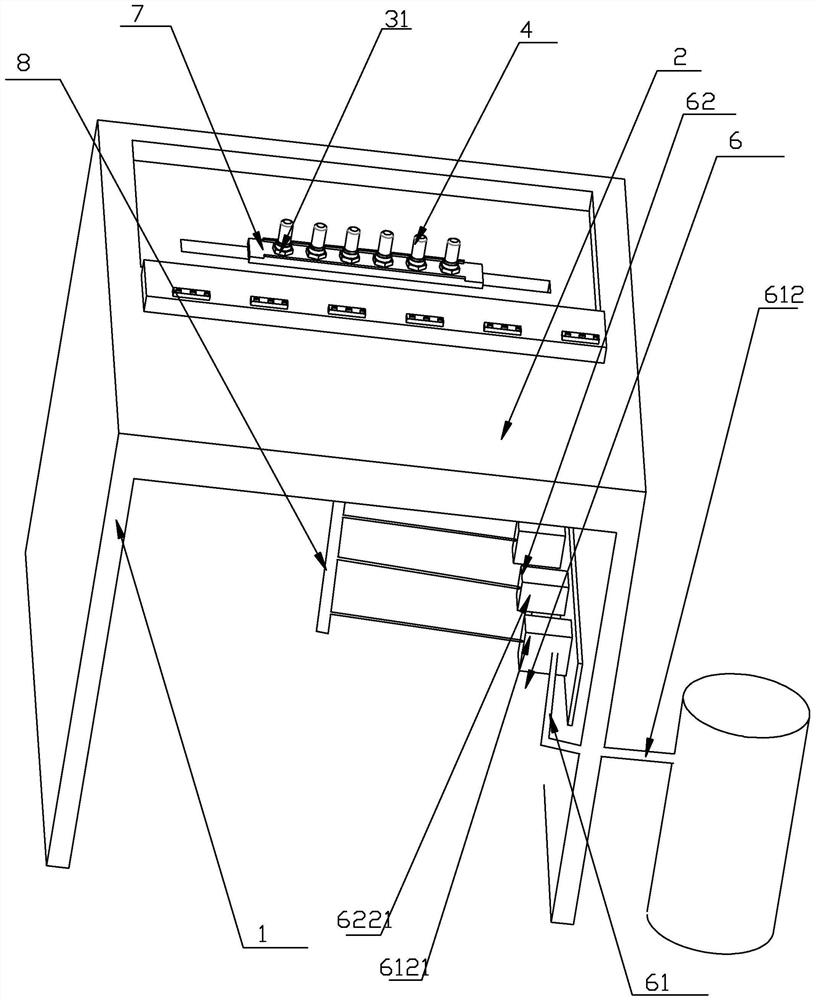

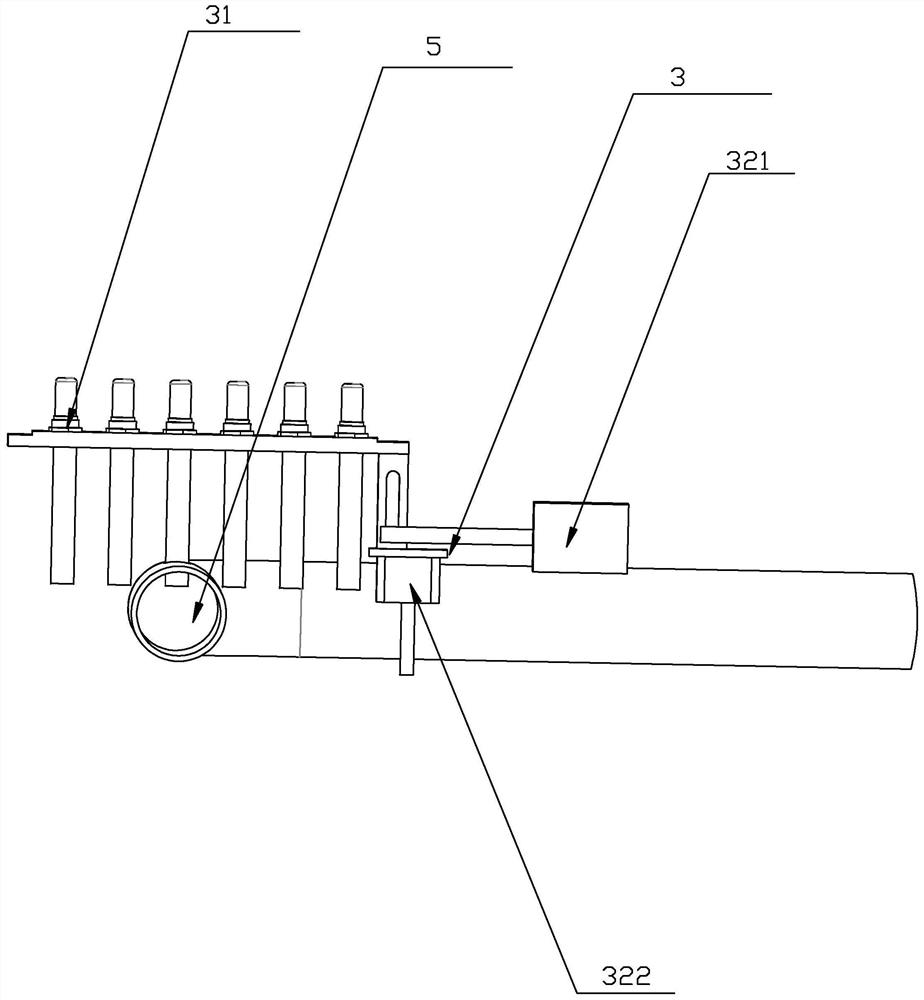

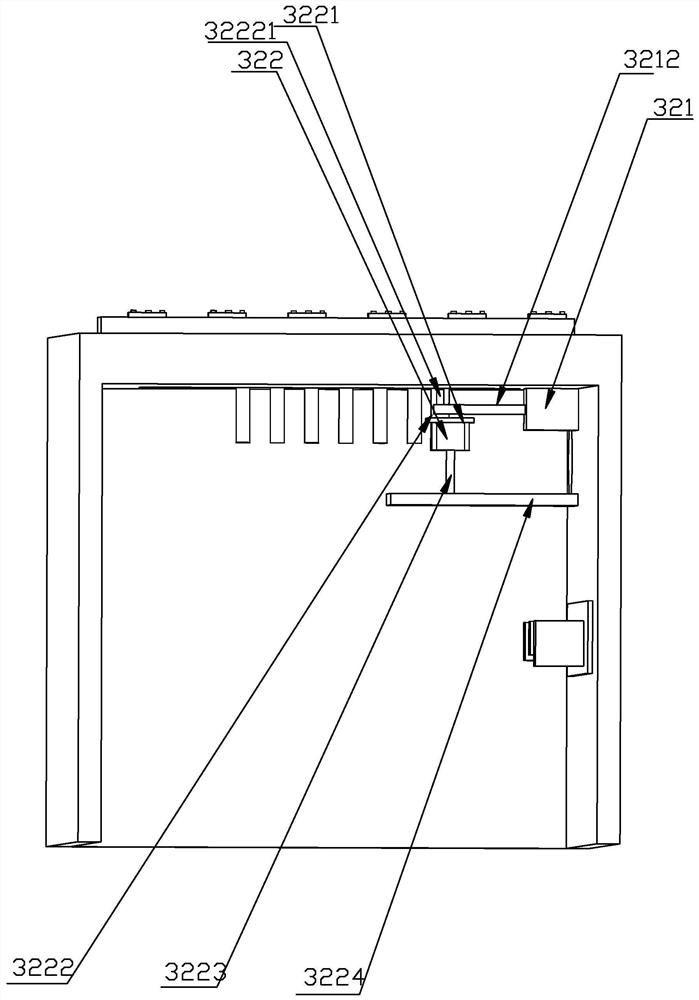

[0020] Such as Figure 1-Figure 3 As shown, it includes a rack 1, a display stand 2 set above the rack 1, a cavity set in the rack 1, and an oxygen sensor environment simulation test system set in the cavity, which drives the oxygen sensor into the oxygen sensor environment simulation The drive system 3 in the test unit and the feedback system 4 that feeds back the test data of the oxygen sensor, the drive system 3 includes an oxygen sensor placement position 31 where the number is greater than one for oxygen sensor placement and drives any oxygen sensor placement position Enter the driver 32 of the oxygen sensor environment simulation test system, and the oxygen sensor environment simulation test system includes a test chamber 5, an ignition assembly that ignites and heats the test chamber 5, a heating unit that heats the oxygen sensor, and controls the temperature in the test chamber. Gas-fuel ratio gas injection unit 6 , the gas injection unit 6 includes a gas intake contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com