Clamping tool tray used for automatic verification line of transformer

A technology for clamping tooling and calibration lines, applied to instruments, measuring devices, measuring electrical variables, etc., can solve problems such as transformer shaking or dumping, and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

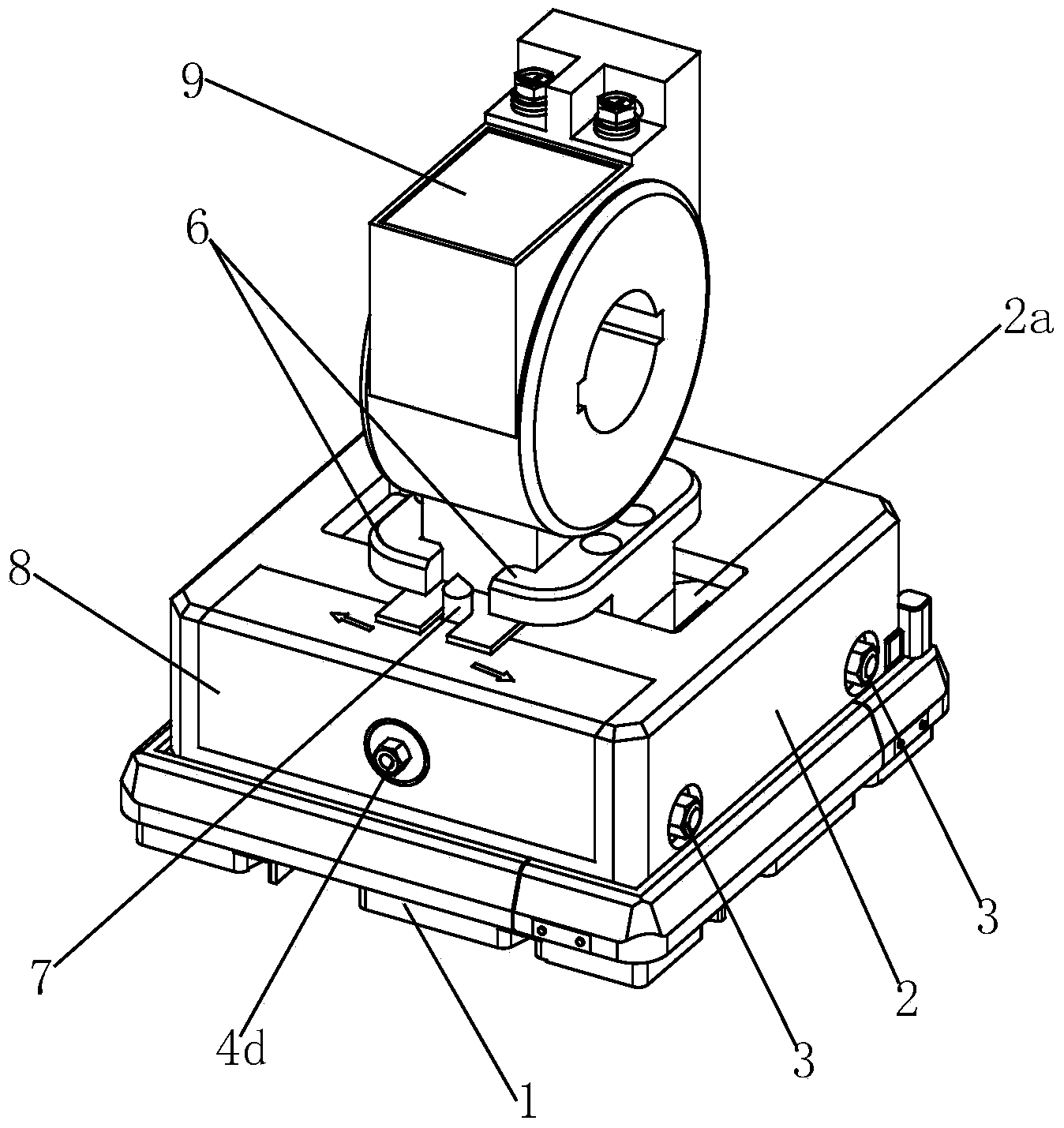

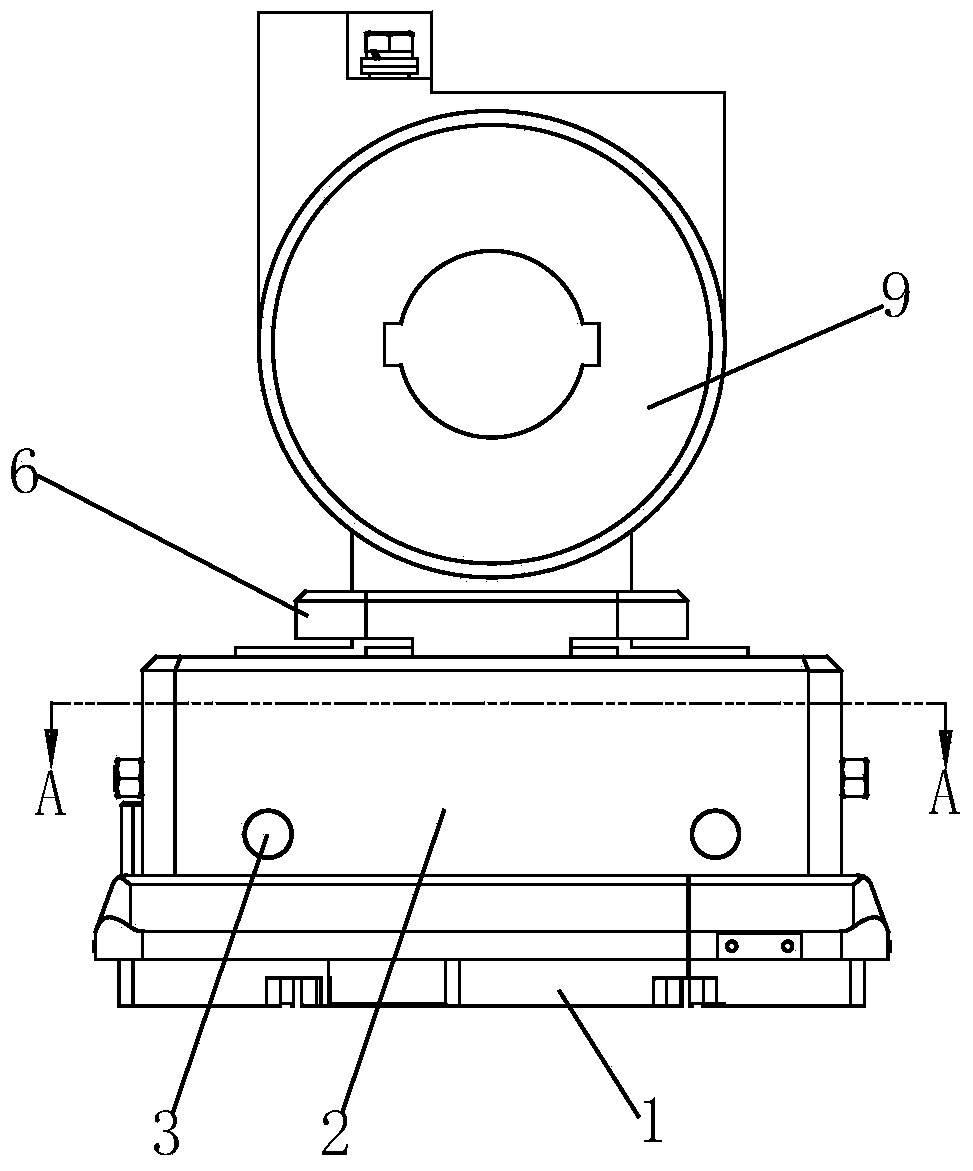

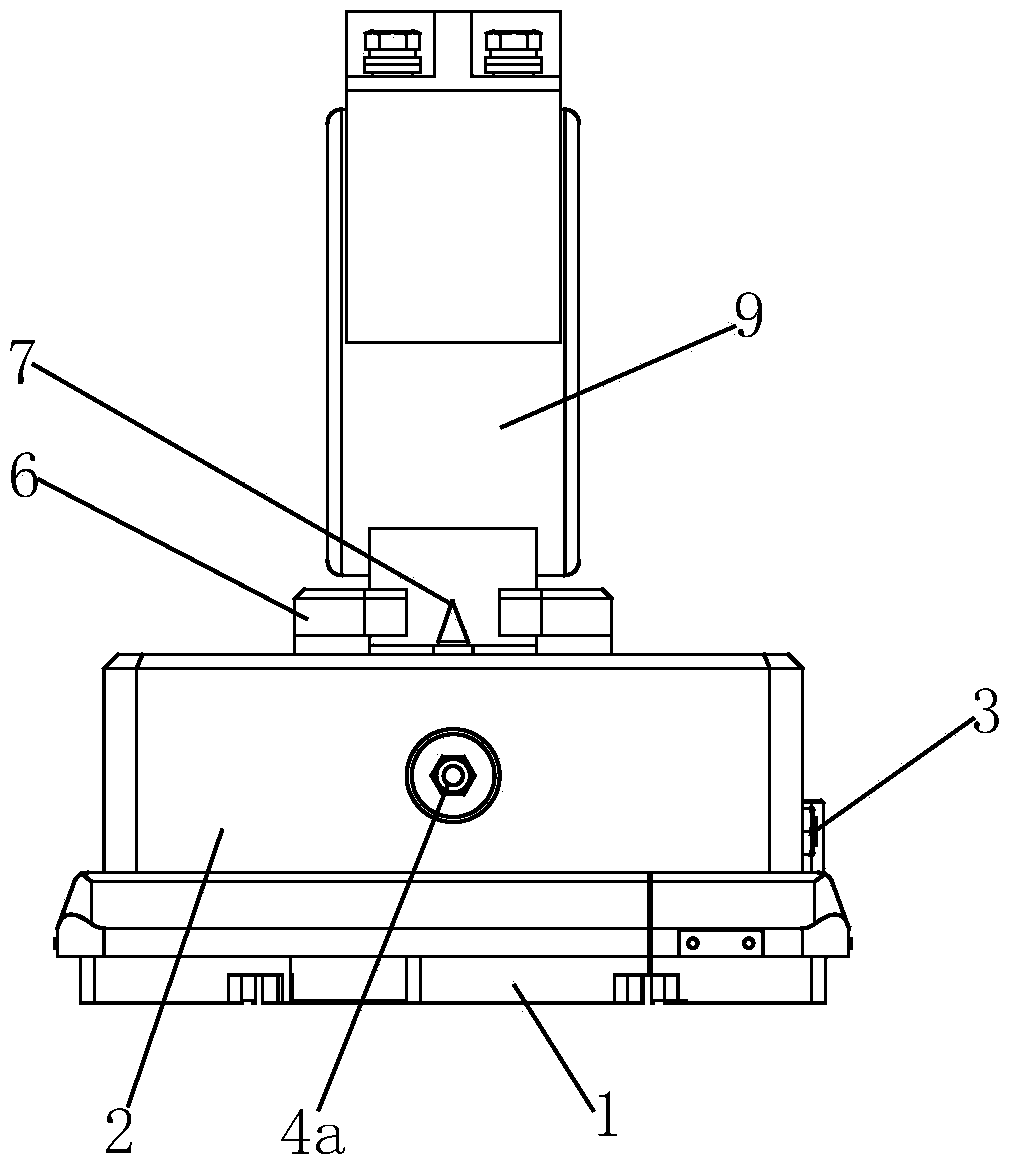

[0024] Such as figure 1 As shown, the present embodiment provides a clamping tooling pallet for transformer automatic test line, including an insulating base 1, and the insulating base 1 is provided with a housing 2 with a through hole 2a on the top, and the housing 2 is provided with a horizontal slide bar 3, on which two sliders 5 with a clamping mechanism 4 are slidably installed, and on the two sliders 5 are installed a clamp for clamping the neck of the transformer 9 Movable clip 6, the insulating base 1 is provided with an opening 1a for the air claw on the automatic verification line to extend into the housing 2. By adopting the technical solution of adding a movable clamp 6 with a clamping mechanism 4 on the insulating base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com