Ultrasonic molecular beam injection device

An injection device and molecular beam technology, applied in the field of nuclear fusion, can solve the problems of plasma feeding efficiency lower than 20%, poor confinement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

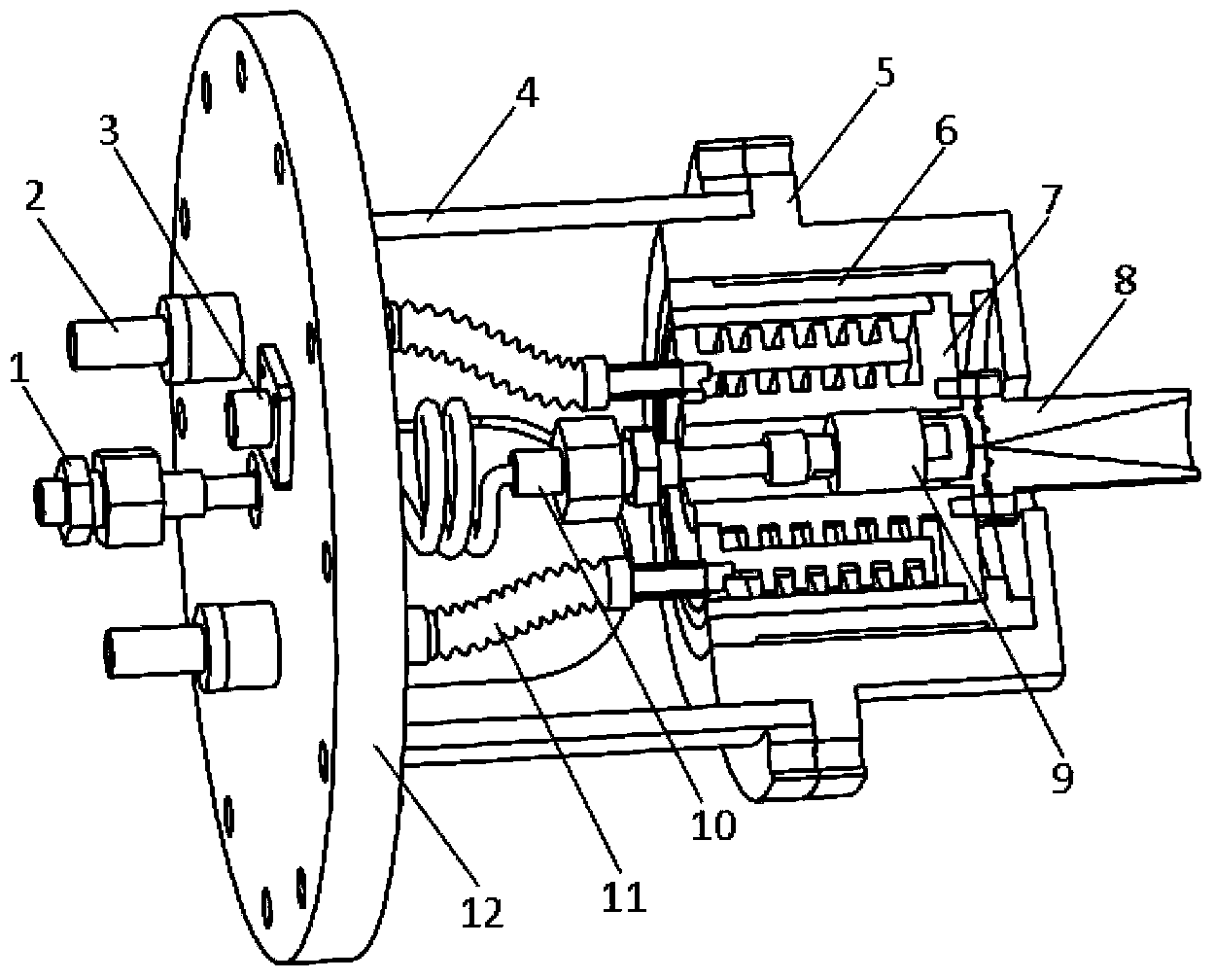

[0027] Such as figure 1 As shown, the ultrasonic molecular beam injection device of the present invention includes: a molecular beam valve 9 , a cold / hot trap heat sink 7 and a magnetic shielding cylinder 5 . Among them, the outlet of the molecular beam valve 9 is provided with an extended Laval nozzle 8, and the molecular beam valve 9 is sequentially nested in the cold / hot sink heat sink 7 and the magnetic shielding tube 5 from the inside to the outside, and is fixed in the fusion On the flange 12 connected to the vacuum chamber of the device.

[0028] The air inlet of the molecular beam valve 9 is connected with the high-pressure gas source through a high-pressure sealing joint; its outlet is provided with an extended Laval nozzle 8, and the aperture of the molecular beam valve 9 outlet is equal to the aperture of the extended Laval nozzle 8 , and are on the same axis. In this embodiment, the outlet aperture of the molecular beam valve 9 has various specifications, ranging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com