Assembly technology for intelligent battery

A smart battery and assembly process technology, which is applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as loss, easy to be corroded by acid, easy to damage chips, etc., to save costs, Good for heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

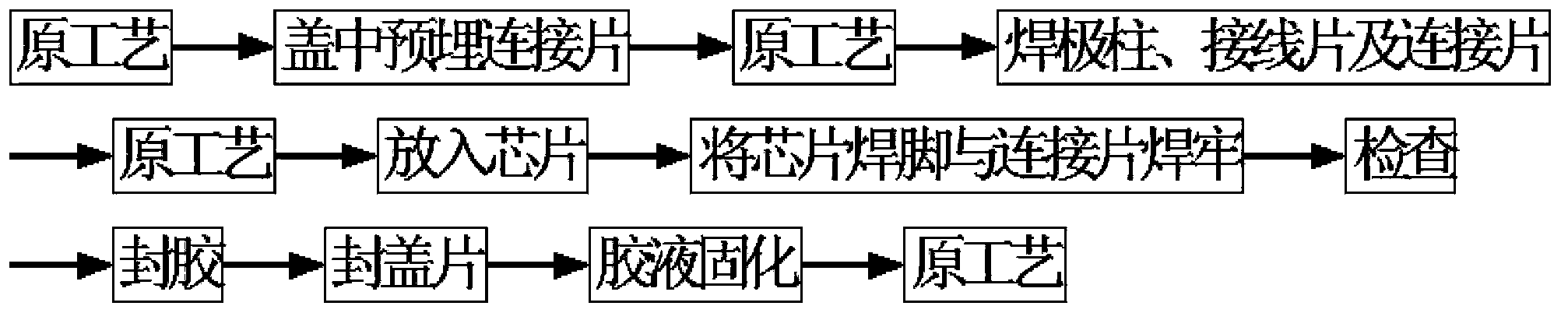

[0017] Combine below figure 1 The smart battery assembly process of the present invention is specifically described.

[0018] The smart battery includes a cover body, and a chip installation groove for installing a smart chip is reserved in the middle of the cover body; in the present invention, the chip is installed on the upper surface of the battery cover, and the chip is welded and glued after the battery is formed and charged and before the cover sheet. Seal it, and the specific process is as follows: Manufacture the plastic casing and plastic cover according to the original process and pre-embed the connecting piece in the cover → produce the plate according to the original process, put the electrode group into the groove → connect the terminal and lug when welding One end of the chip is welded firmly with the pole terminal → capping, acid injection, chemical formation according to the original process → put in the chip (there are three-point positioning and error-proof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com