Handheld Cotton Pickers

A cotton picker and hand-held technology, applied in the field of hand-held cotton pickers, can solve the problems of affecting work efficiency, manual removal and high cost, and achieve the effects of reducing the probability of entanglement, improving efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

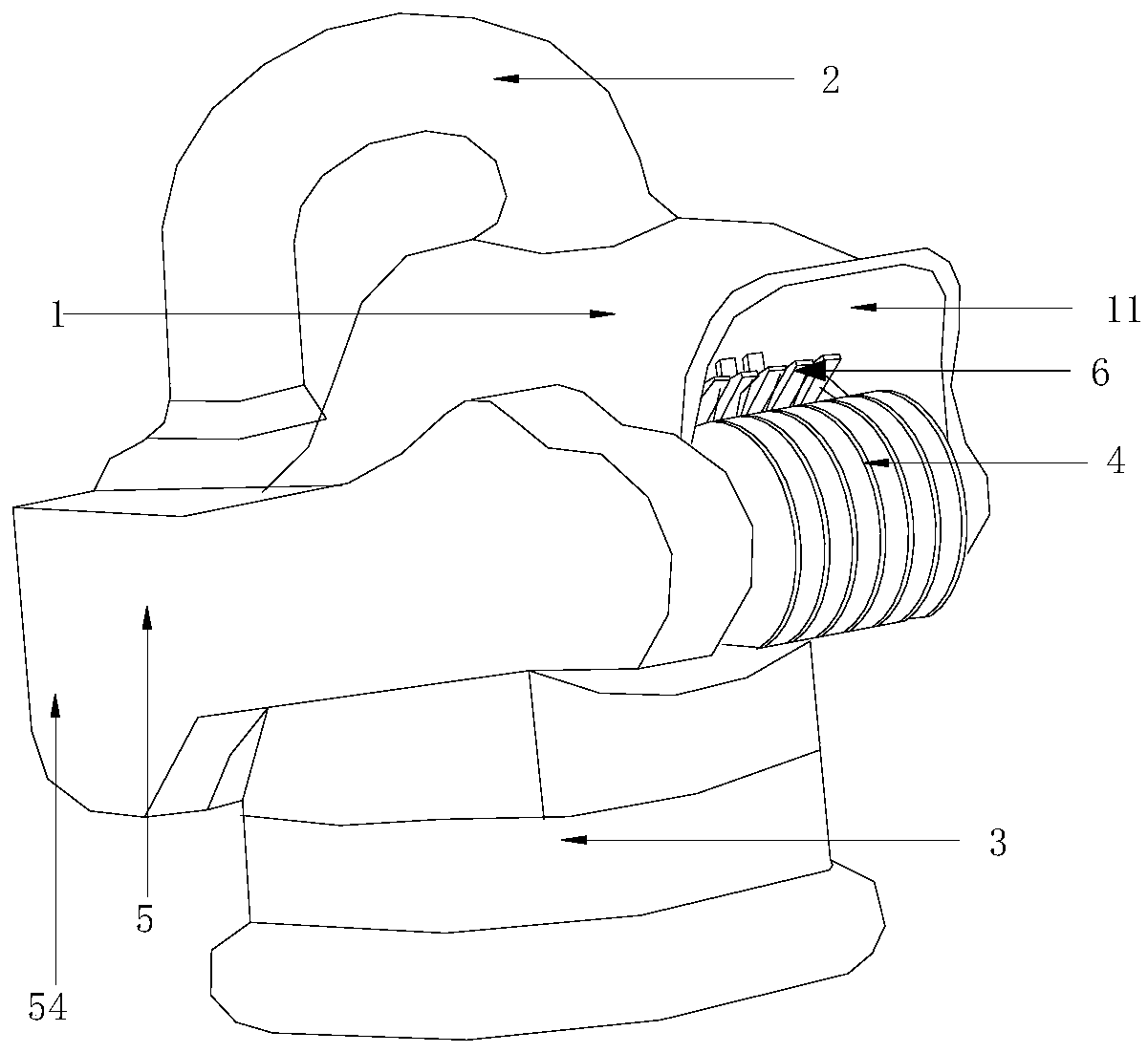

Embodiment 1

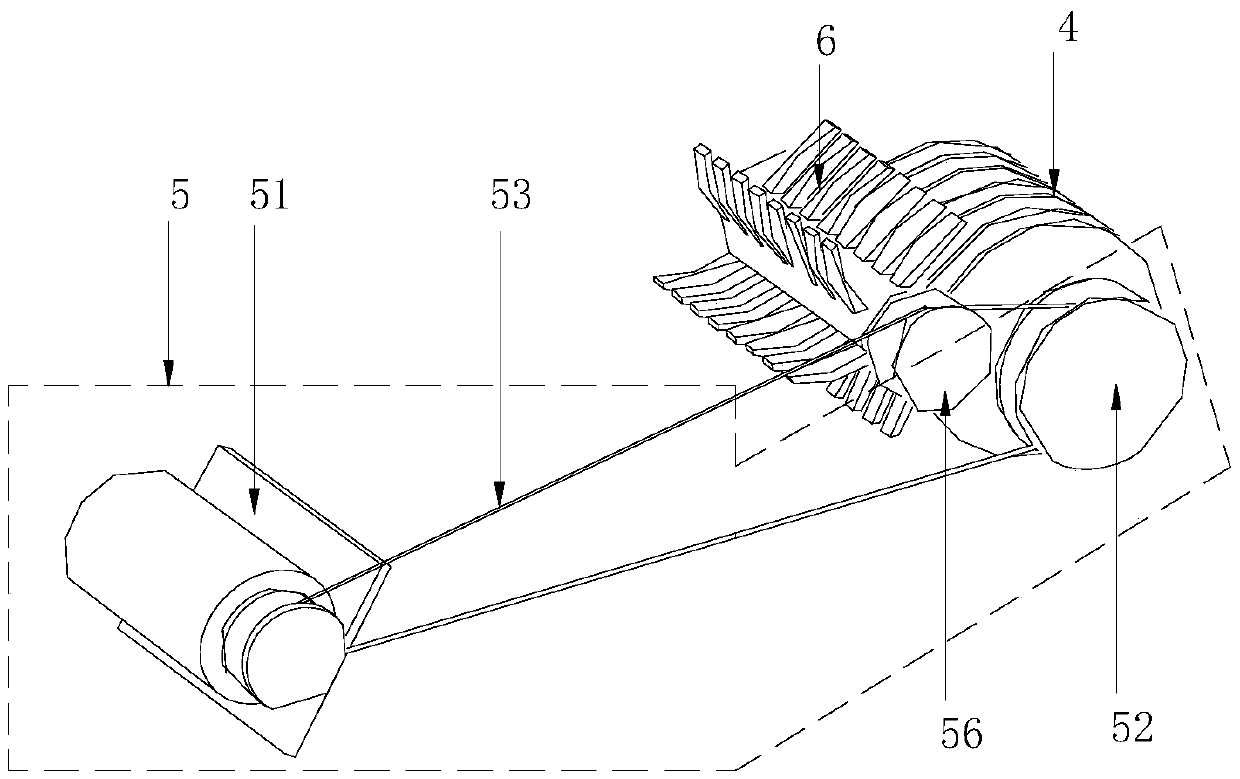

[0063] The collection head 4 includes 4 groups of hooking sheets, and each group of hooking sheets is provided with 9 sawtooths on the outer edge, that is, m'=4, m=9;

[0064] The separator 6 is 5 groups of separation wheels, each group of separation wheels is provided with 5 blades, that is, n'=5, n=5;

[0065] The speed of the separator is twice the speed of the collection head, that is, k=2.

[0066] Figure 6 The separator shape of a preferred embodiment of the present invention is shown.

[0067] Such as Figure 6 As shown, the blades 62 of the separator 6 are arranged in an arc shape bent in a direction opposite to the direction of rotation of the separator. The blades 62 of the separator 6 are arranged in a curved arc shape, so that the cotton fibers on the blades can be better shaken off by the action of centrifugal force, and the probability of silk entanglement in the separator is greatly reduced.

Embodiment 2

[0069] The collection head includes 6 sets of cotton hooks, and each set of cotton hooks has 6 sawtooths on the outer edge, that is, m'=6, m=6;

[0070] The separator is 7 sets of separation wheels, each set of separation wheels is provided with 3 or 4 blades, that is, n'=7, n=3 or 4, and the blades are arranged in a straight line;

[0071] The rotating speed of the separator is 3 times of the collecting head rotating speed, namely k=3.

Embodiment 3

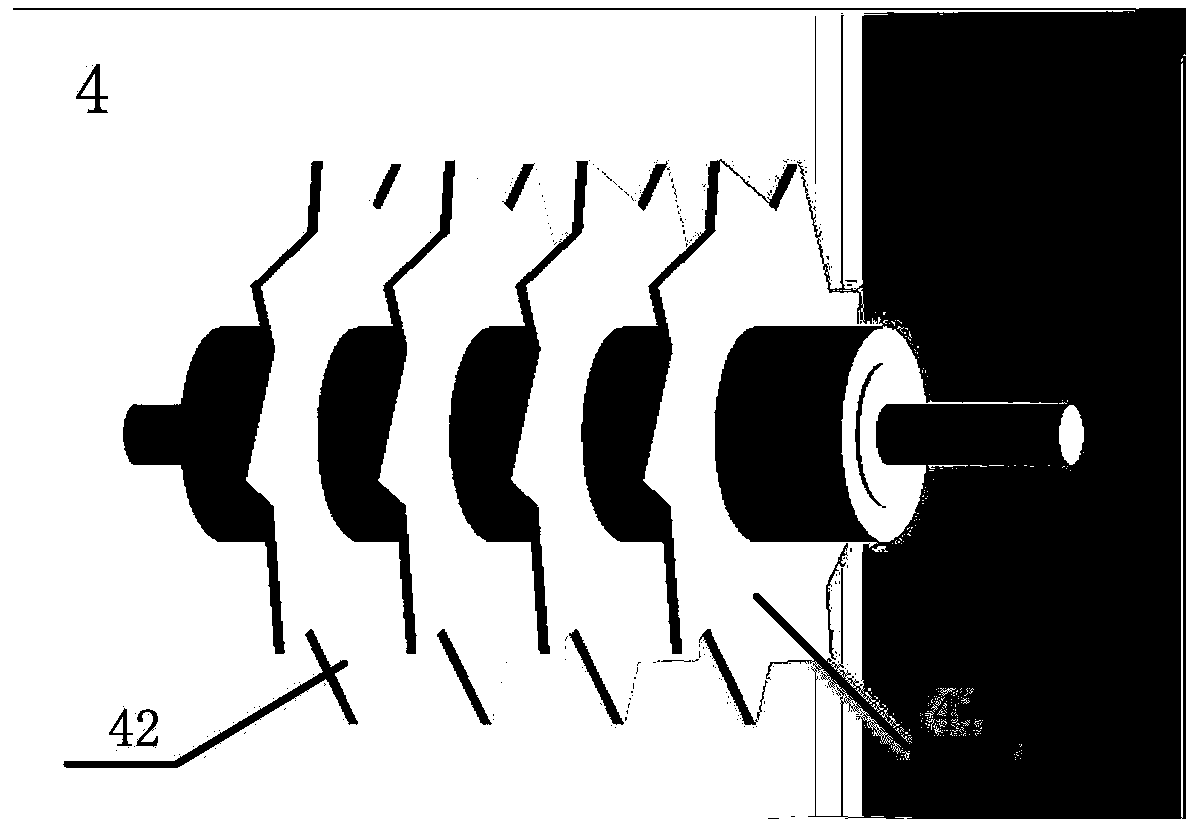

[0073] Figure 7 It shows the shape of the hooking sheet of the collection head in a preferred embodiment of the present invention.

[0074] Such as Figure 7 As shown, the shape of the sawtooth 42 on the snagging piece 41 of the collection head 4 in this embodiment is preferably formed approximately at a right angle, and the angle range of the right angle is 90±5°.

[0075] More preferably, the right-angled sawtooth is a right angle inclined towards the rotation direction of the collection head, as shown in the figure, that is, the short side of the right angle is on the side facing the rotation direction of the collection head, and the short side of the right angle is adjacent to the previous right angle The long side is also formed as an approximate right angle, and the angle range of the right angle is 90±5°.

[0076] Such a configuration of the sawtooth can make it easier for the hook piece of the collection head to hook the cotton, significantly improve the success rat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap