Tea-frying machine

A tea frying machine and frame technology, applied in the field of tea making tools, can solve the problems of low degree of mechanization, improve efficiency, low precision, etc., achieve the effect of coordinating working relationship and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

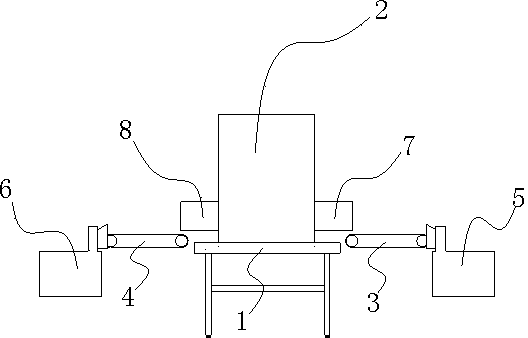

[0010] according to figure 1 As shown, the tea frying machine in the present invention includes a frame 1, a drum type fixing pot 2 arranged on the frame 1, a first conveyor belt 3, a second conveyor belt 4, a first hui pot 5 and a second conveyor belt Erhui Pot6.

[0011] Wherein, the bottom of the drum-type fixing pot 2 is provided with a first discharge port 7 and a second discharge port 8, and each of the first and second discharge ports 7 and 8 is provided with a discharge valve. The feed section of a conveyor belt 3 is located at the first discharge port 7, the discharge section of the first conveyor belt 3 is connected to the feed port of the first boiler 5, and the second conveyor The feed section of the belt 4 is located at the second discharge port 8 , and the discharge section of the second conveyor belt 4 is connected to the feed port of the second boiler 6 .

[0012] The first and second Hui pots 5 and 6 are respectively provided with outlets, and the finished t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com