Thrust runner collar grinding platform

A technology for grinding platforms and mirror plates, which is applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems that mirror plate grinding devices cannot be ground and the grinding efficiency is low, and achieve the goals of improving grinding efficiency, simple structure, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

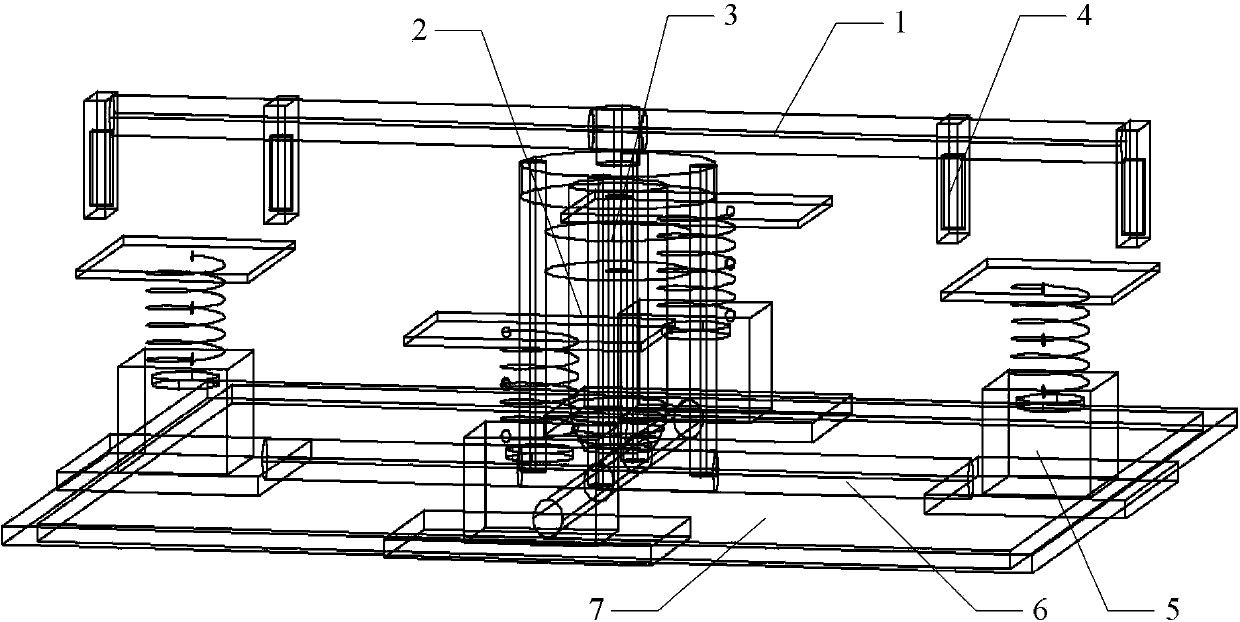

[0010] Specific implementation mode 1. Combination figure 1 Illustrate this specific embodiment, a mirror plate grinding platform, which includes a rotating rod 1, a motor 2, a transmission 3, four fixed plates 4, four support platforms 5, a connecting frame 6 and a platform base 7, the motor 2 The stator is fixed at the center of the platform base 7, and four support platforms 5 are fixedly installed on the platform base 7. The height of each support platform 5 is the same, and every two support platforms 5 are symmetrical about the central axis of the rotor of the motor 2. Each support The distances between platform 5 and the central axis of the rotor of motor 2 are equal, and each supporting platform 5 is connected to the stator of motor 2 through a connecting frame 6. The center of rotating rod 1 is fixed on the output shaft of motor 2, and rotating rod 1 is connected to The platform base 7 is parallel, and the transmission 3 is used to control the speed of the motor 2. Ev...

specific Embodiment approach 2

[0014] Embodiment 2. The difference between this embodiment and the mirror plate grinding platform described in Embodiment 1 is that the support platform 5 includes a support platform, a support spring and a support base, and the support platform and the support base are fixed by the support spring connect.

[0015] In this embodiment, the support table 5 has a good adjustment function and adjustment range, which can ensure that the mirror plate can always be kept in a horizontal state at the construction site, and ensure the normal progress of the grinding work of the mirror plate.

[0016] In this embodiment, the support table 5 can ensure that the mirror plate is in a horizontal state all the time during the grinding process, so as to ensure the smooth completion of the mirror plate grinding.

specific Embodiment approach 3

[0017] Embodiment 3. The difference between this embodiment and the mirror plate grinding platform described in Embodiment 2 is that the width of each set of fixing plates 4 is equal to or smaller than the width of the support platform.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap