Illuminating system and engineering machinery

A lighting system and engineering machinery technology, which is applied in the fields of earthmoving machines/shovels, construction, optical signals, etc., can solve problems such as hidden dangers of safe operation of excavators, inconvenient work at night, collisions, etc., to improve operation safety, eliminate The effect of lighting blind spots and expanding lighting areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

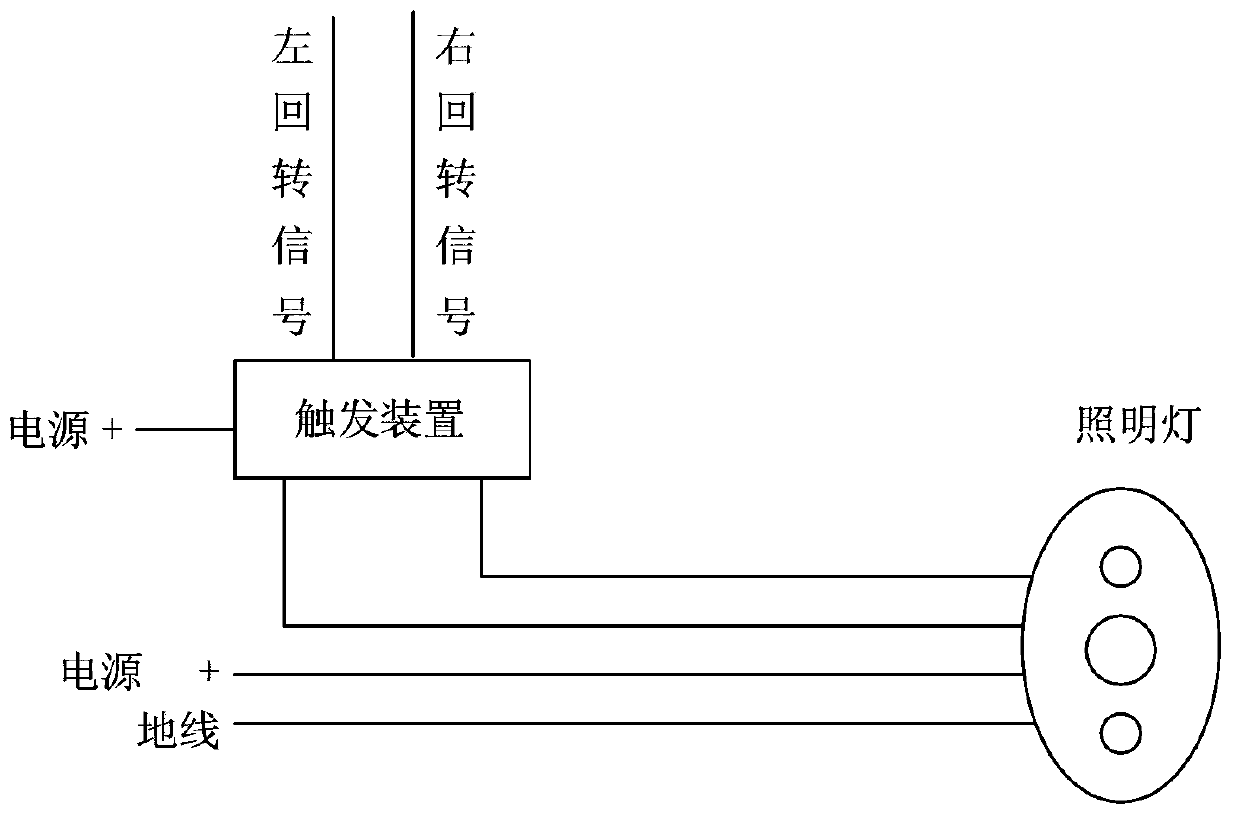

[0027] refer to figure 1 , shows the lighting system of this embodiment, and the lighting system includes: a power supply device, a signal acquisition device for collecting rotation signals, a trigger device, a main lighting lamp and an auxiliary lighting lamp for expanding the lighting area. Wherein, the main lighting lamp and the auxiliary lighting lamp are connected to the power supply device, and the trigger device is arranged on the connection line between the auxiliary lighting lamp and the power supply device. The trigger device is connected with the signal acquisition device, and is used to control the opening and closing of the auxiliary lighting lamp according to the rotation signal.

[0028] In this example, if figure 1 As shown, the lighting includes main lighting and auxiliary lighting. Among them, the main lighting is used to illuminate the area in the same direction as the axle, and the auxiliary lighting can be used to activate the auxiliary lighting function...

no. 2 example

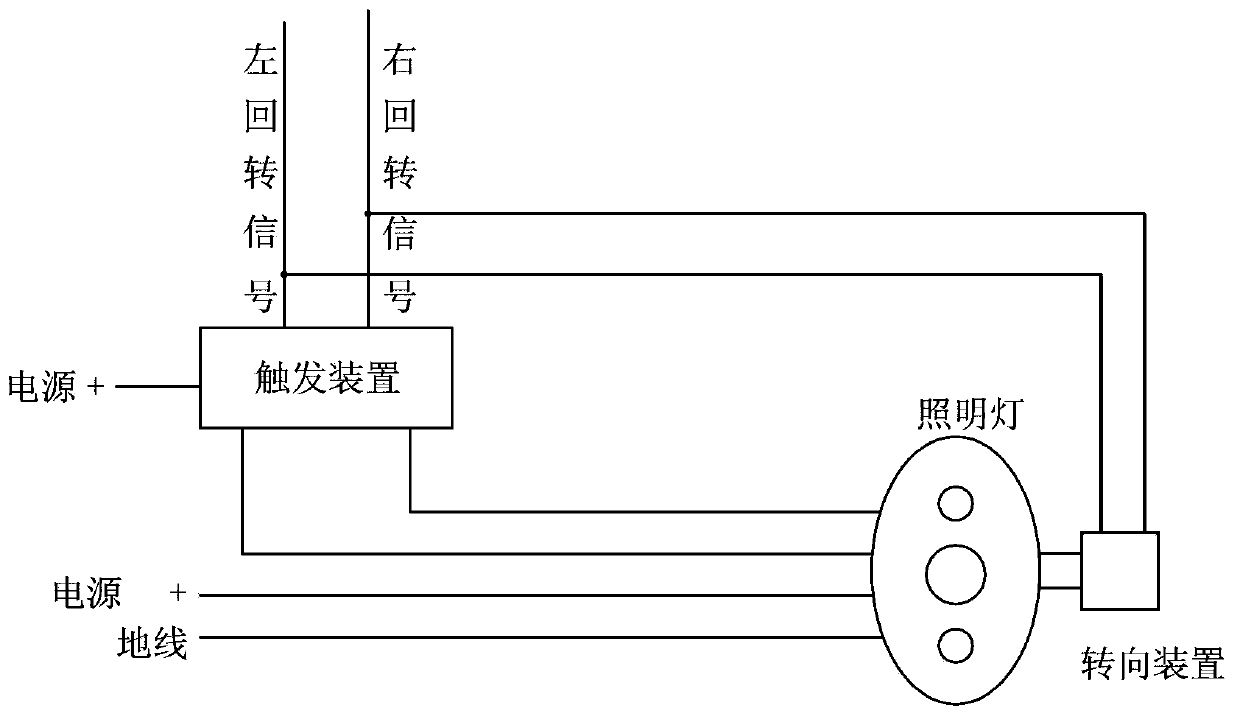

[0036] refer to figure 2 , shows the lighting system of this embodiment, and the lighting system includes: a power supply device, a signal acquisition device for collecting a slewing signal, a trigger device, a main lighting lamp, an auxiliary lighting lamp for expanding the lighting area, and a A turn signal that changes the direction of the lighting. Wherein, the main lighting lamp and the auxiliary lighting lamp are connected to the power supply device, and the trigger device is arranged on the connection line between the auxiliary lighting lamp and the power supply device. The steering unit is connected to the main and auxiliary lights. The trigger device is connected with the signal acquisition device, and is used to control the opening and closing of the auxiliary lighting lamp according to the rotation signal.

[0037] In an optional embodiment, the steering device includes: a first steering device for controlling the lighting direction to turn left, and a second ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com