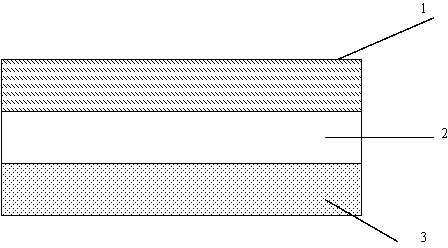

Packaging adhesive film for solar cell module

A solar cell and encapsulation adhesive film technology, which is applied in the direction of electrical components, circuits, adhesives, etc., can solve problems such as the decrease of the interface between EVA and glass, the safety hazard of solar cell components, and the inability to effectively solve the PID phenomenon, etc., to achieve an excellent layer Interadhesion, improved service life, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1 part by weight of silane-grafted LDPE (SX522A: CM401 from AEI Compounds), 65 parts by weight of vinyl POE (EXACT5062 from ExxonMobil, melting peak is 43°C), 35 parts by weight of ethylene-α-olefin Block copolymer (INFUSE9000 of DOW chemical company, the melt flow rate measured under the condition of 190 ℃ 2.16kg is 0.5g / 10min) and the additive of 1.5 parts by weight are fully mixed to form the material of polyolefin adhesive layer; 60 Parts by weight of vinyl POE (TAFMER DF940 from Mitsui Chemicals, melting peak is 77°C), 40 parts by weight of ethylene-α-olefin block copolymer (INFUSE9530 from DOW Chemical Company, measured at 190°C under 2.16kg The melt flow rate is 5g / 10min) and 1.5 parts by weight of additives are fully mixed to form the material of the polyolefin barrier layer; according to the thickness of the polyolefin adhesive layer of 10 μm and the thickness of the polyolefin barrier layer of 180 μm, the material after mixing the two layers Two extruders are ...

Embodiment 2

[0042] 30 parts by weight of silane-grafted MDPE (SX720: CM488 from AEI Compounds), 95 parts by weight of vinyl POE (ENGAGE8401 from DOW Chemical, melting peak is 80°C), 5 parts by weight of ethylene-α-olefin block Copolymer (INFUSE9530 of DOW Chemical Company, the melt flow rate measured under the condition of 190 ℃ 2.16kg is 5g / 10min) and 1.5 parts by weight of additives are fully mixed to form the material of polyolefin adhesive layer; 90 parts by weight of Vinyl POE (EXACT5062 of Exxon Mobil, the melting peak is 43°C), 10 parts by weight of ethylene-α-olefin block copolymer (INFUSE9000 of DOW Chemical Company, the melt flow measured under the condition of 190°C 2.16kg speed is 0.5g / 10min) and 1.5 parts by weight of additives are fully mixed to form the material of the polyolefin barrier layer; according to the thickness of the polyolefin adhesive layer of 50 μm and the thickness of the polyolefin barrier layer of 400 μm, the mixed material of the two layers is used in two ...

Embodiment 3

[0044] 5 parts by weight of silane-grafted LLDPE (LINKLON XLE815N from Mitsubishi Chemical Corporation), 75 parts by weight of vinyl POE (DF710 from Mitsui Chemicals, melting peak at 59°C), and 25 parts by weight of ethylene-α-olefin block copolymerization The material (INFUSE9100 of DOW chemical company, the melt flow rate measured under the condition of 190 ℃ 2.16kg is 1g / 10min) and 1.5 parts by weight of additives are fully mixed to form the material of polyolefin bonding layer; 60 parts by weight of ethylene Based POE (EXACT5062 of Exxon Mobil, the melting peak is 43°C), 40 parts by weight of ethylene-α-olefin block copolymer (INFUSE9000 of DOW Chemical Company, the melt flow rate measured under the condition of 190°C 2.16kg 0.5g / 10min) and 1.5 parts by weight of additives are fully mixed to form the material of the polyolefin barrier layer; according to the thickness of the polyolefin adhesive layer of 10μm and the thickness of the polyolefin barrier layer of 400μm, the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap