A cord steel refining material and its preparation method

A cord steel and equipment technology, which is applied in the field of steelmaking and refining, can solve the problems of increasing the probability of white spot defects in steel, unfavorable cost control, and large energy consumption, so as to improve the unstable composition, hard texture, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

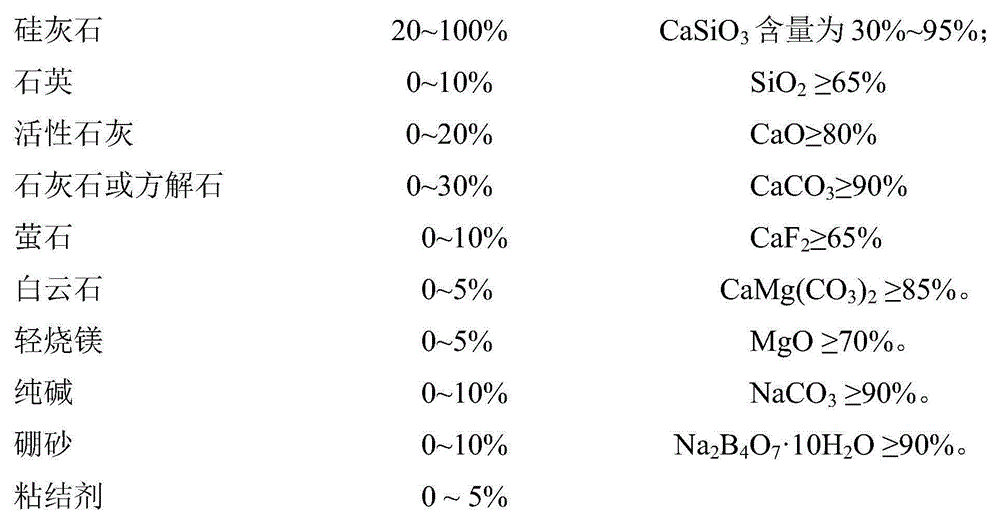

[0024] Weigh CaSiO 3 Content is 90%, 60 mesh wollastonite 2000kg, CaO content is 89%, 100 mesh active lime 200kg, NaCO 3 20kg of industrial soda ash with a content of 90%.

[0025] ②Mix in closed pre-mixing equipment;

[0026] ②Mechanically formed under the pressure of 35MPa, it is a sphere of ∮25~∮40mm.

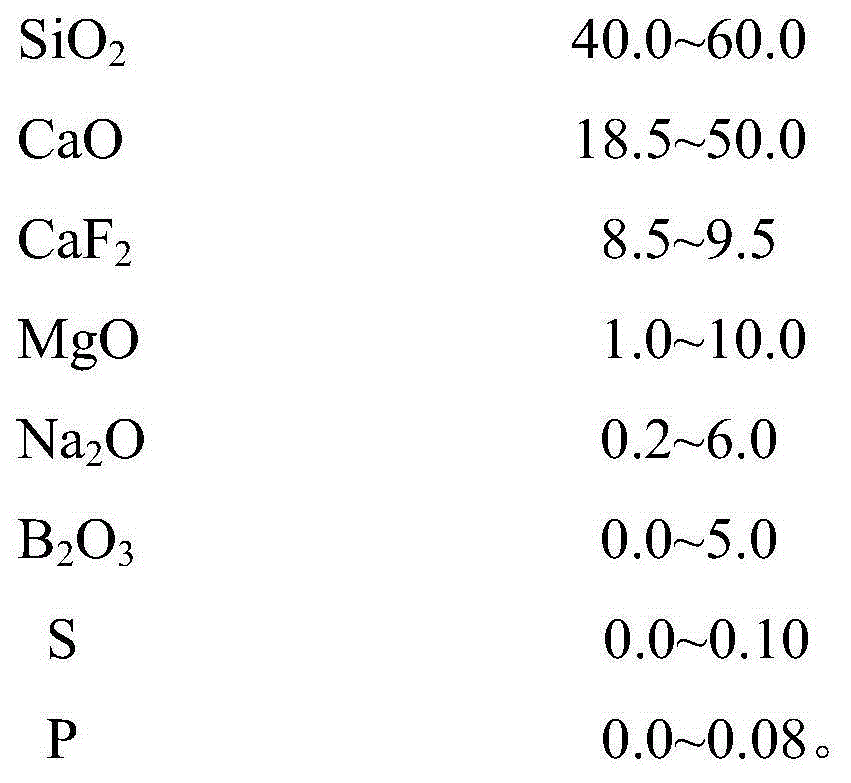

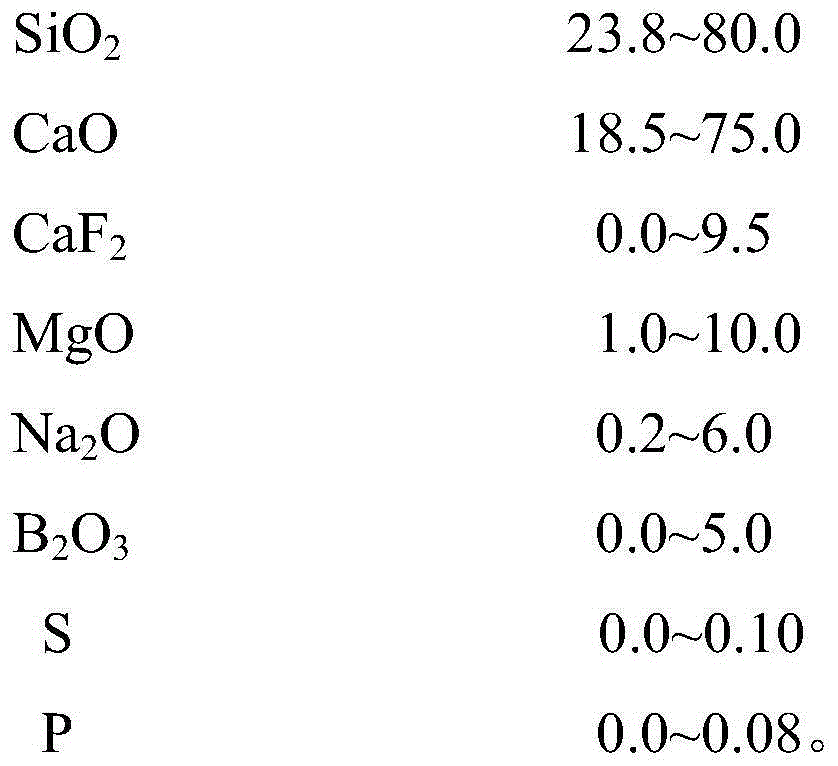

[0027] The detected component content is SiO 2 : 42.3%, CaO: 47.6%, MgO: 1.18%, Na 2 O: 0.48%, trace amount of impurities.

Embodiment 2

[0029] The cleaning agent obtained in Example 1 was tested in the following process: converter tapping-RH-LF-soft argon blowing and stirring-continuous casting-prime rolling-rolling wire rod process. During the tapping process, it is added to molten steel for slag washing, and the addition amount is 6-8kg / t. After tapping, the molten steel is sent to RH for vacuum treatment. After the RH treatment, the molten steel reaches LF refining. Before refining, 6-8kg / t of purifying agent is added. After LF refining is completed for 45 minutes, it enters other processes. The condition of non-metallic inclusions in the steel sample was tested by SEM, which showed that: with this refined material, the number of inclusions decreased and the size became smaller. 1-2um inclusions accounted for 80% of the total, and inclusions larger than 5um were rarely, to 5% of the total. The inclusion composition consists of brittle and hard Al 2 o 3 into CaO-SiO 2 -Al 2 o 3 system, the melting poin...

Embodiment 3

[0031] ① Weighing CaSiO 3 The content is 68%, 60 mesh wollastonite 1500kg, CaO content is 88%, 100 mesh active lime 12g, CaF 2 The content is 85%, 40 mesh fluorite 180kg, mixed in closed pre-mixing equipment;

[0032] ②Mechanically formed under the pressure of 35MPa, it is a sphere of ∮15~∮40.

[0033] The detected component content is SiO 2 : 39.5%, CaO: 47.6%, CaF 2 : 9.2%, MgO: 2.58%, Na 2 O: 0.26%, trace amount of impurities.

[0034] The purifying agent was added to molten steel in 23 furnaces for testing, and the inclusions detected by the metallographic microscope of the steel sample were significantly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com