Multi-layer crossed corrugated steel plate composite component and method for welding detection of same

A corrugated steel plate, multi-layer crossing technology, applied in bridge parts, bridges, buildings, etc., can solve the problem that corrugated plates cannot be laminated to each other, and achieve the effect of expanding the scope of use, stabilizing usability, and ensuring welding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

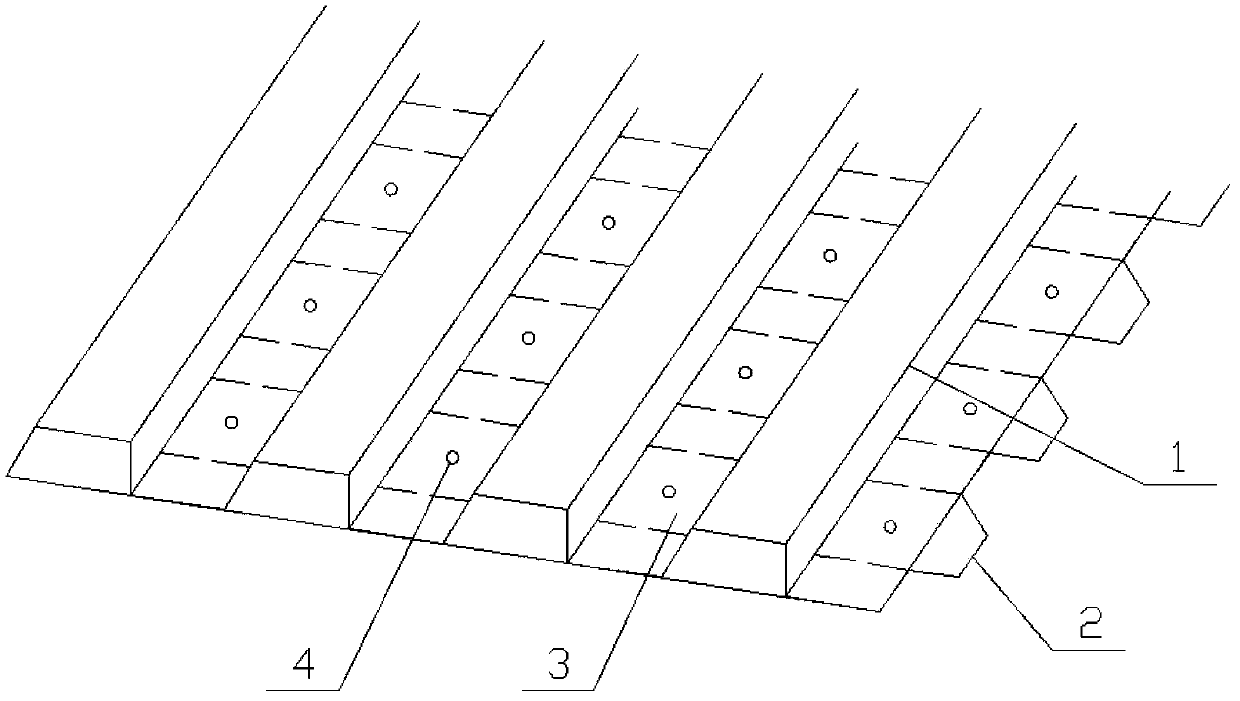

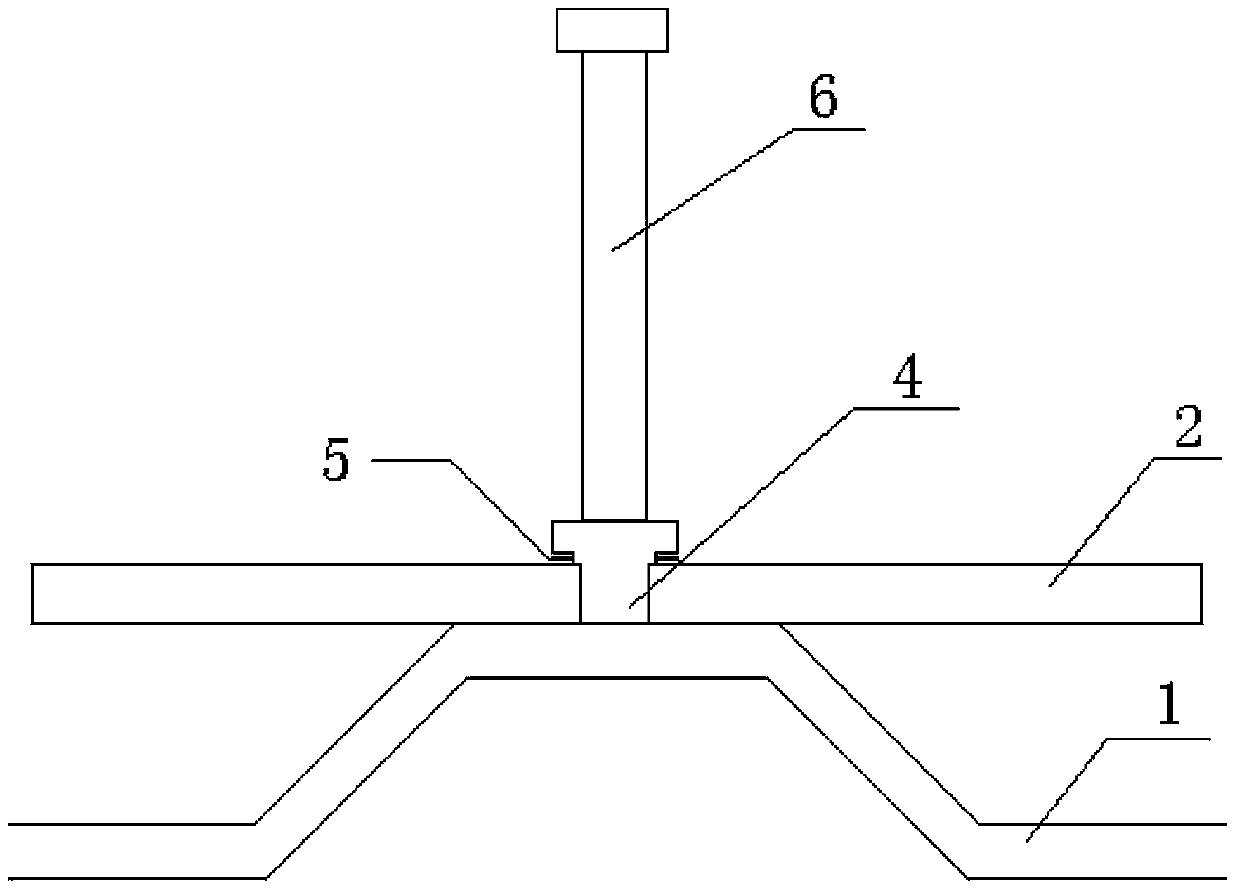

[0020] Multi-layer cross corrugated steel plate composite member, including longitudinal corrugated plate 1, transverse corrugated plate 2, peg 4, longitudinal corrugated plate 1 and transverse corrugated plate 2 intersected, the trough or crest of longitudinal corrugated plate 1 and the crest of transverse corrugated plate 2 Or the troughs intersect and contact each other, and there are holes on the corrugated plate, and the diameter of the holes is greater than or equal to the rod diameter of the peg 4 .

[0021] The net length of the peg 4 is greater than or equal to the thickness of the perforated corrugated plate.

[0022] The stud 4 is welded with a stud machine to the corrugated plate in the other direction through the opening.

[0023] The nail cap of the stud 4 is located outside the perforated corrugated plate, and the inner side of the cap is in contact with the perforated corrugated plate, and an insulating isolation ring 5 is provided between the stud cap and the ...

Embodiment 2

[0029] A welding detection method for a multi-layer cross corrugated steel plate composite member, comprising the following steps:

[0030] a. Weld the second stud 6 of the same diameter outside the cap of the welded stud 4;

[0031] b. Cut off the welding section by 3%-20%;

[0032] c. Perform a pull or / and bend test on the outer second peg 6 .

[0033] The detection method is sampling detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com