Connecting device

A connecting device and cylinder technology, applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of deformation and falling off of the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

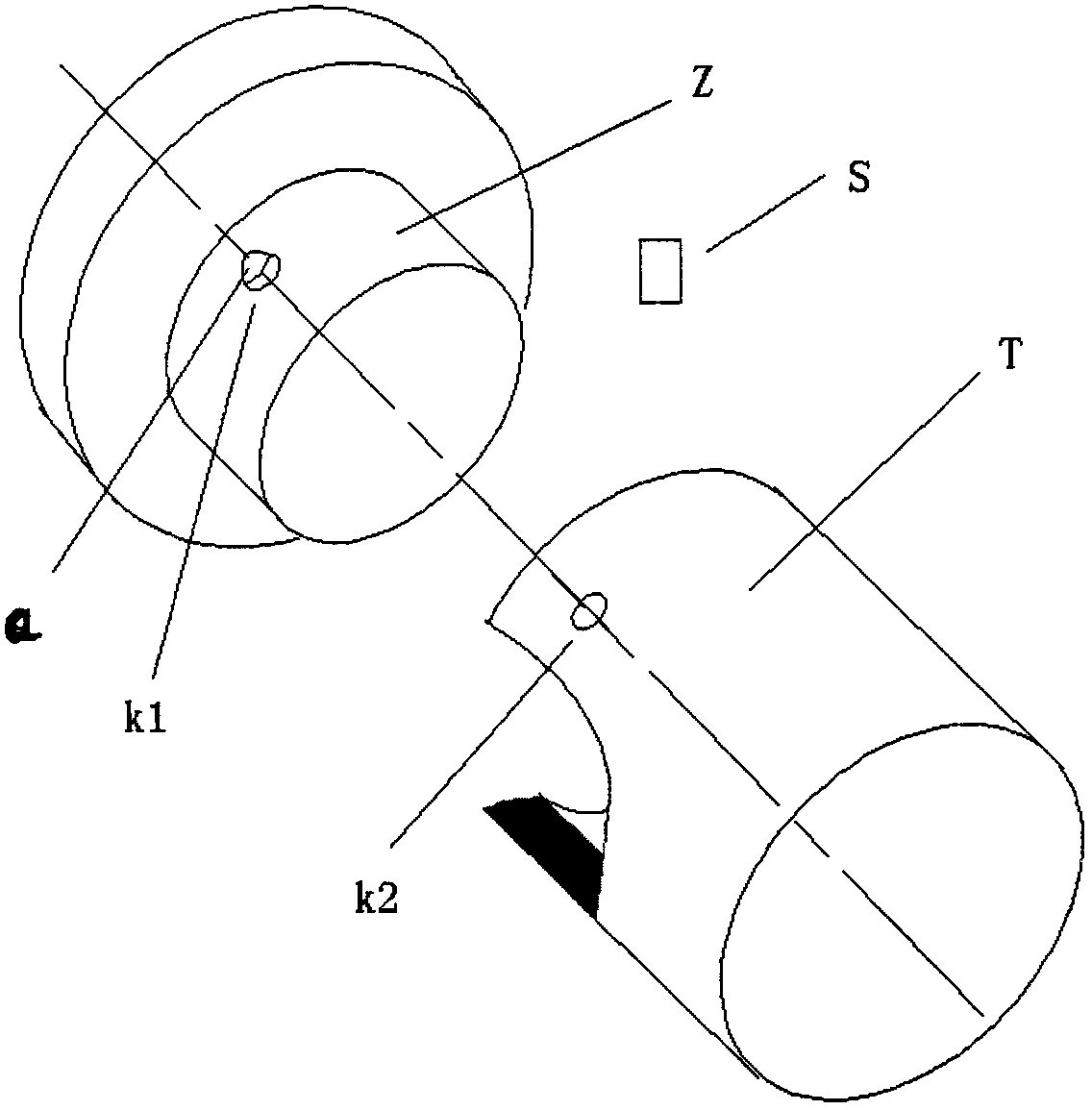

[0008] exist figure 1 Among them, there is a circular hole K1 and a curved surface Q on the connecting device cylinder Z, and a circular hole K2 on the connecting device cylinder T, and the lock pin S is inserted in the circular holes K1 and K2.

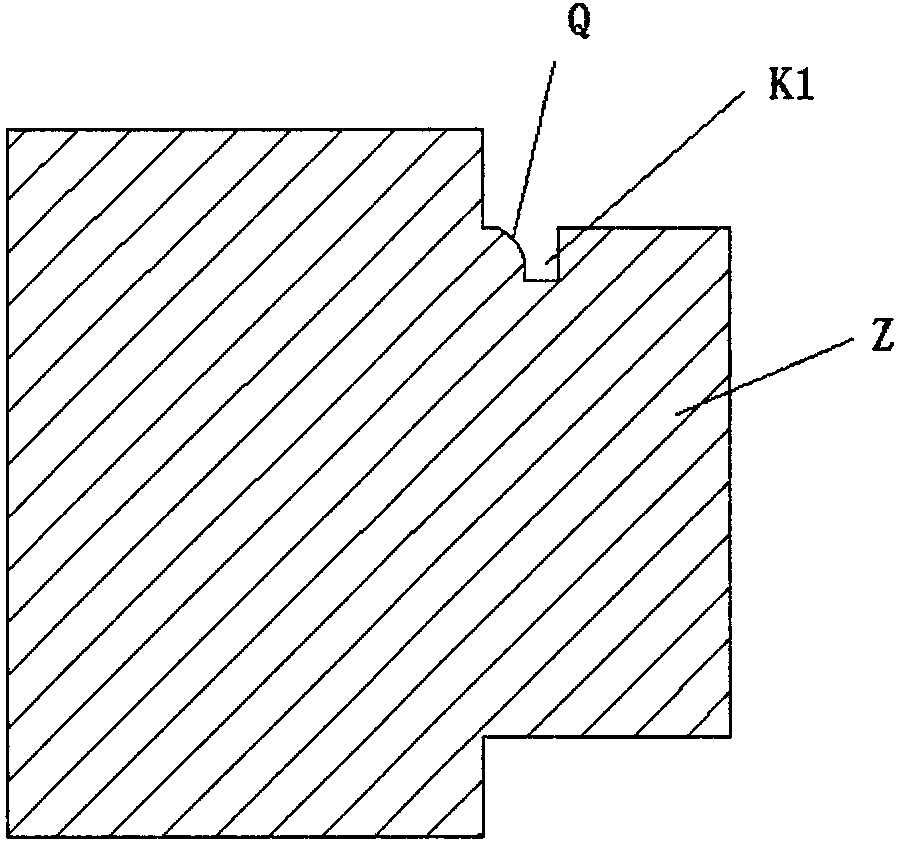

[0009] exist figure 2 Among them, the connecting device cylinder Z has a circular hole K1 perpendicular to the axial direction, and the diameter of the circular hole K1 gradually increases on the side of the cylinder Z close to the part, forming a curved surface Q.

[0010] exist image 3 , the lock pin S is a cylinder.

[0011] exist Figure 4 , the cylinder Z extends into the cylinder T, the round hole K1 on the lock pin cylinder Z is aligned with the round hole K2 on the cylinder T, and the lock pin S is inserted, and the applied opposite force makes the lock pin S The deformation rests on the surface Q.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com